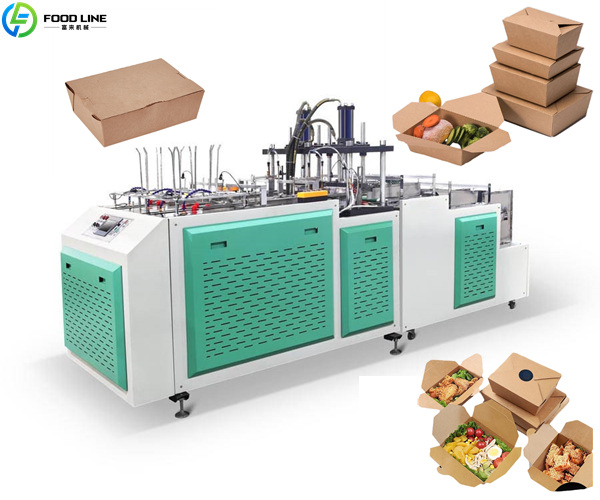

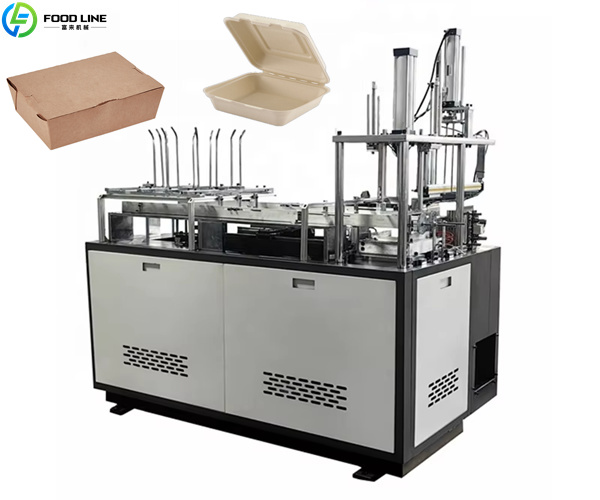

The food box forming machine is a fully automatic paper product forming machine that integrates pneumatic and mechanical motions. Designed specifically for the production of lunch box packaging containers, it can be used for disposable paper lunch boxes with lids, paper lunch boxes, and kraft paper food packaging boxes. This machine integrates automation technology and mechanical design, automating the entire process from paper feeding, forming, to box collection. It is a key piece of equipment for food packaging companies to achieve large-scale, standardized production.

Welcome to consult! WhatsApp/Phone: +86 13838385752.

Specifications of Food Container Making Machine

| Specification | Details |

|---|---|

| Model | FL-400 |

| Production Capacity | 35~45 pcs/min |

| Maximum Paper Size | 480x480mm |

| Suitable Material | 200~400g/m² PE coated paper, etc. |

| Total Power | 5kw |

| Voltage Requirement | 220V 50HZ |

| Total Weight | 350kg |

Working Principle of the Food Box Forming Machine

- The paper feed mechanism precisely delivers raw materials, such as PE-coated paper, to designated workstations.

- Equipment’s heating device heats the paper to the ideal forming temperature.

- The pneumatic and mechanical systems work in tandem to complete the forming processes of the lunch boxes, including pressing, folding, and sealing the bottom.

- Finished lunch boxes are collected by a box collection mechanism, completing the entire production cycle.

Advantages of the Lunch Box Forming Machine

Production Efficiency

The food box forming machine boasts a production speed of 35-45 pieces/minute, several times higher than traditional manual or semi-automated production. For large-scale orders from restaurant chains and food processing companies, it can quickly complete production tasks and shorten delivery cycles.

Product Compatibility

The machine supports coated paper such as PE-coated paper with a weight of 200-400g/㎡, and can produce a wide range of packaging types, including lunch boxes with lids, kraft paper boxes, and two-compartment boxes. Whether it’s fast food boxes or customized kraft paper packaging, the food box forming machine can meet production needs.

Reduced Operating Costs

With fully automated production, the machine can be operated by one person, reducing labor input. Furthermore, the machine’s highly precise mechanical motion control reduces material waste due to operator error, saving companies both labor and material costs.

Stable Quality

Through the coordinated pneumatic and mechanical motions, and the support of a fault monitoring system, the food box forming machine produces lunch boxes with secure bonding and a consistent shape. Stable quality not only enhances brand image, but also reduces the risk of customer complaints and returns due to packaging defects.

Features of Paper Food Container Machine

Pneumatic and Mechanical Fusion

The combination of pneumatic and mechanical motion offers the advantages of high speed, ease of operation, high efficiency, and environmental friendliness. The pneumatic system ensures flexible movement, while the mechanical structure ensures precision and stability. The two work together to ensure a more reliable lunch box forming process.

Intelligent Control System

Equipped with a touchscreen intelligent control system, the operator can intuitively set production parameters, enabling precise control of paper feeding, heating, forming, and box collection. Furthermore, the equipment features fault monitoring, providing timely warnings of any anomalies, facilitating troubleshooting and resolution.

Structure

The equipment features a modular design, with each functional unit independently connected and tightly interconnected. Routine maintenance allows for inspection and repair of specific modules without disassembling the entire machine. Functional expansion or capacity upgrades can also be achieved through module replacement.

Environmental Protection

The materials used, such as PE-coated paper, meet environmentally friendly food packaging requirements. The equipment boasts high production efficiency and excellent energy efficiency, reducing carbon emissions during production. This food box forming machine helps companies implement environmental protection principles and enhance their brand image.

Free Quote! WhatsApp/Tel: +86 13838385752.

FAQ

The machine weighs 350kg and must be placed on a flat surface. The power supply must be 220V 50Hz, and ventilation must be maintained to facilitate heat dissipation and daily operation.

Yes. By replacing the mold with the corresponding specifications, the food box forming machine can produce lunch boxes of different sizes. The mold replacement process is simple.

About Foodline Equipment

- Rich export experience

- Professional technical team

- CE certification

- After-sales service

Choosing our equipment will give you reliable equipment and a reliable partner. We also have food sterilizers. Welcome to consult us for more information!