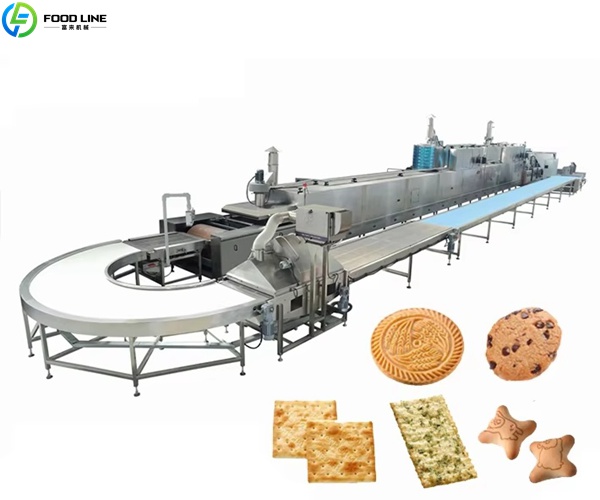

Whether you produce soft-baked cookies or crispy cookies, Foodline Machinery’s automatic biscuit production line can help you simplify your operation process, reduce labor costs, and ensure product quality. Would you like to know more about this line? Contact us for a free consultation and quote! WhatsApp/Phone: +86 13838385752.

Machines of Biscuit Production Line

| Equipment | Specifications | Voltage | Power | Dimensions (mm) | Weight |

|---|---|---|---|---|---|

| Dough Mixer | Best mixing capacity: 10 bags/flour per batch | 380V | 28kW (mixing), 0.75kW (tipping) | 2400×1550×1996 | 2200kg |

| Dough Slicer | Slice width: 600mm, Thickness: 10-100mm (adjustable), Hydraulic pressure: 6.3MPa | 24V/220V/380V | 4.1kW | 2600×1060×1200 | 620kg |

| Dough Lift Conveyor | Lift height: 2000mm, Conveyor width: 1000mm | 220V/380V | 1.5kW | 5200×1060×2000 | – |

| Three-Roll Dough Sheeter | Sheeting width: 800mm, Thickness: 10-20mm, 3 refrigerated rollers | – | – | 1600×1810×1250 | 1280kg |

| Two-Roll Dough Sheeter | Sheeting width: 1000mm, Thickness: 2-10mm, 2 refrigerated rollers | – | 6.36kW (total) | 1600×1610×1250 (×2 units) | 1280kg |

| Tough Biscuit Forming Machine | Sheeting width: 1000mm, Thickness: 0.7-20mm | – | 1.85kW | 2200×1810×1250 | 1100kg |

| Dough Separation Machine | PU belt width: 1000mm, Return belt width: 1000mm | 380V | 2.2kW | 1950×1810×1450 | – |

| Two-Stage Feeder | Conveyor PU width: 1000mm | – | 1.1kW (×2 units) | Upper: 9600×1050×1900, Lower: 8200×1050×1700 | – |

| Biscuit Spraying Machine | Conveyor width: 1020mm, Air pressure: 0.1-0.25Pa | 380V/24V | 0.55kW | 1200×1300×600 | – |

| Biscuit Transition Machine | Conveyor width: 820mm, Arm length: 1500mm | – | 1.1kW | 2140×1610×1020 | – |

| Pre-Oven Conveyor | Air pressure: 8-10kgf/m² | – | – | 1800×1930×1100 | 850kg |

| Electric Tunnel Oven (40m) | Production: 1350kg/h (crisp), 900kg/h (tough), Heating zones: 3, Width: 1200mm | – | 20kW (burners), 3.75kW (fans), 1.1kW (slag removal) | 40000×2040×1400 | 22000kg |

| Oven Control Cabinet | – | – | – | 1000×300×1700 | 120kg |

| Post-Oven Conveyor | – | 380V | 3kW | 1800×1930×1100 | 800kg |

| Crumb Separator | – | 380V | 0.75kW | 1200×1280×900 | 180kg |

| 90° Turning Machine | Heating power: 2kW | 380V | – | 2100×2100×850 | 250kg |

| Biscuit Oil Sprayer | Heating power: 16kW | 380V | – | 2000×1280×1400 | 580kg |

| Oil Drain Cooling Line | – | 380V | 1.1kW | 6000×1220×800 | 280kg |

| Lift Conveyor (10m) + 3-Tier Cooling Line (10m×3) | – | 380V | 6kW | 10000×820×1800 (lift), 10000×820×1800×3 (cooling) | 3500kg |

| Biscuit Arranger | – | 380V | 3.75kW | 3500×1300×1000 | 450kg |

| Biscuit Sorting Table | – | 380V | 2kW | 10000×1220×780 | 350kg |

| Biscuit Molds | Roller length: 1000mm, Diameter: 250mm | – | – | – | 30kg |

| Vibrating Biscuit Dropper | – | 220V | 0.25kW | 2000×350×1000 | – |

| High-Speed Pillow Packager | Speed: 100-300 packs/min, Film width: <360mm | 220V | 4.8kW | 3900×800×1550 | 500kg |

| 10kW Air Compressor | – | – | 10kW | – | – |

Biscuit Line Features

- Multi-dough compatibility: supports the production of both crisp and hard dough biscuits. And equipped with adjustable equipment modules.

- Precision forming system: equipped with customizable rotary molds that can be replaced or adjusted according to different biscuit shapes and sizes.

- High-efficiency oven: 40-meter tunnel oven with independent temperature zones, insulation and digital control to ensure uniform baking.

- Integrated recycling system: Dough scraps are recycled through the return conveyor to improve raw material utilization and reduce waste.

- Advanced conveyor: From the 90° turn conveyor to the three-layer cooling system. Each conveying stage adopts a stainless steel frame and an automatic correction function to ensure stable biscuit handling.

- Automatic oiling: Our crisp biscuit equipment is equipped with a centrifugal oiling system to ensure uniform oiling.

Each function is carefully designed to increase production and improve energy efficiency.

Advantages of Automatic Biscuit Production Line

- Reduce labor costs

- Ensure product size, color and texture quality

- Customizable modules to achieve product diversification

- Dough recycling, high material utilization

- Support electric, gas or diesel heating

- Modular structure, easy to clean and maintain

Workflow Overview: Two Processes for Two Biscuit Types

Our production line is suitable for both crisp and hard biscuit types. Here’s how each process flows:

Crisp Biscuit Workflow:

- Dough Mixing

- Dough Cutting

- Lifting Conveying

- Rotary Molding

- Scrap Separation

- Scrap Return Conveyor

- Water Spraying

- Oven Infeed

- Baking (Tunnel Oven)

- Oven Output

- Crumb Separation

- Turning Conveyor

- Cooling Conveyor

- Biscuit Alignment

- Packaging

Hard Biscuit Workflow:

- Dough Mixing

- Dough Cutting

- Lifting Conveyor

- Four-stage Rolling Compression

- Rotary Cutting & Molding

- Biscuit Scrap Recycling

- Water Spraying

- Oven Loading

- Baking

- Post-Bake Transfer

- Crumb Separation

- Oil Spraying

- Oil Draining & Cooling

- Multi-Tier Cooling

- Alignment

- Packaging

The two workflows use shared infrastructure, making it easy for one production line to switch between different product types.

Customer Case Study

Case 1: Nguyen Van Duc, CEO of a US snack food company, shared his story: “Before upgrading to the Foodline biscuit line, we relied on manual forming and batch ovens. With the new line, we doubled our production and reduced energy consumption. We now produce two lines simultaneously on one equipment – crispy butter biscuits and coconut-flavored hard biscuits.”

Case 2: Mr. Youssef’s factory originally used a semi-manual method to make crispy biscuits. Although the sales volume of the products was stable, the labor cost was high, and the yield rate was low. So he introduced a complete set of cookie production lines from Foodline Machinery. The modified production line only needs a few operators to maintain an efficient production capacity of more than 600 kilograms per day. More importantly, with the help of this highly automated cookie production line, Youssef met the peak season orders of the local market and successfully expanded the brand to the overseas market, doubling the production and increasing revenue in just one year.

Foodline Machinery-Your Trust Partner

Choose Foodline Machinery. You don’t just buy a machine, you work with a team of engineers, designers, and food production experts with more than 20 years of experience. Here’s why global brands trust us:

- End-to-end service: from layout design, installation, training to after-sales support.

- Excellent manufacturing quality: all materials are food-grade certified.

- Custom engineering: modular systems tailored to customer recipes and factory layout.

Our customers benefit from more than just machines. They get a long-term, successful partner. Whether you are building a new facility or upgrading an old one, our cookie production lines provide the speed, quality, and automation you need to stay ahead in today’s competitive market. In addition, we also have cookie forming machines. Contact us today for a free consultation and customized production line proposal! WhatsApp/Phone: +86 13838385752.