Highly efficient equipment is key to enhancing a company’s competitiveness in the food packaging industry. The food container making machine is the core equipment for forming paper and plastic packaging. Contact us today! WhatsApp/Phone: +86 13838385752.

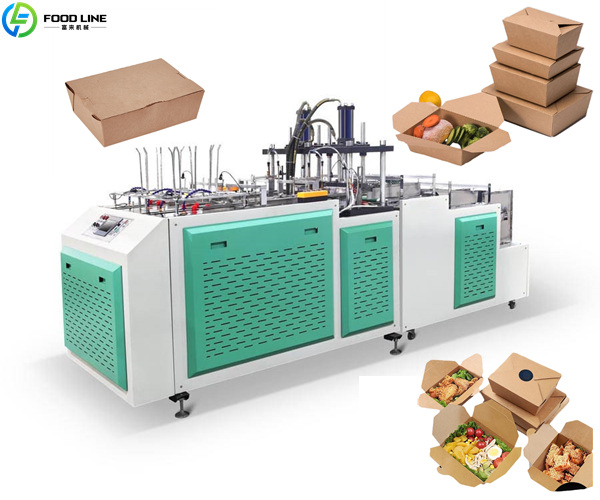

Food Container Making Equipment Overview

This food container making machine is a fully automatic paper product forming machine used in the food packaging industry. It can be used to produce various paper and plastic food trays, lunch boxes, and other packaging containers. Our food tray making machine utilizes aluminum alloy molds, ensuring both precision and durability. It efficiently completes the entire automated production process, from paper feeding, heating, hot pressing, and box collection. This provides an integrated solution for food packaging companies, meeting market demand for high-quality food trays.

Parameters of Food Box Making Machine

| Specification | Details |

|---|---|

| Model | FL-100 |

| Production Capacity | 20~30 pcs/min |

| Maximum Paper Size | 300x270mm |

| Suitable Material | 200~400g/m² PE coated paper, etc. |

| Total Power | 5kw |

| Voltage Requirement | 380V 50HZ |

| Total Weight | 1000kg |

Features of Food Container Making Machine

Intelligent

Equipped with a microcomputer control system and touch-screen interface, operators can intuitively set and adjust production parameters. This allows for control over paper feeding, heating temperature, hot pressing time, and box collection. The simple and easy-to-understand operation process allows even novice operators to quickly master the machine.

Structural Design

The lunch box forming machine’s functional components are strategically arranged, facilitating routine maintenance and troubleshooting. Furthermore, the machine’s compact footprint allows for efficient use of production space.

Material

The aluminum alloy mold combines high precision, light weight, and durability. During high-volume production, the mold is less likely to deform, ensuring product forming accuracy. Furthermore, aluminum alloy facilitates heat dissipation, extending the mold’s lifespan and reducing replacement costs.

Environmental Performance

The laminated paper and other materials used in the production process are recyclable or biodegradable, aligning with the growing trend for green packaging. Furthermore, the machine boasts high production efficiency and energy efficiency, reducing energy consumption and carbon emissions during production.

Free Quote! WhatsApp/Tel: +86 13838385752.

Advantages of Food Box Forming Equipment

Improved Production Efficiency

Traditional manual or semi-automated production methods are inefficient, while the food container making machine fully automates the entire process. With a production speed of 20-30 times per minute, this equipment shortens production cycles, enabling companies to respond to market orders and complete large-scale production tasks in a short period of time, thereby increasing overall production capacity.

Stable Quality

The machine utilizes high-precision aluminum alloy molds, and a microcomputer program controls the paper feeding, heating, and hot pressing processes, ensuring that the food trays produced have excellent bonding and a beautiful appearance. This quality not only enhances the product’s market competitiveness but also reduces customer complaints and rework costs caused by quality fluctuations.

Reduced Labor Costs

The food container making machine is easy to operate, allowing one person to operate multiple units. This saves manpower and reduces labor management costs for companies. It also reduces losses caused by manual errors.

Compatible Materials

It can accommodate coated papers such as laminated paper with a weight of 200-400g/㎡, meeting the material requirements of various food packaging materials. Whether it is an ordinary food tray or a product with special requirements for moisture and oil resistance, it can be produced by this equipment.

Working Principle of Paper Box Forming Machine

The food container making machine’s workflow consists of the following key steps:

- The raw materials, such as laminated paper, are transported to a designated location via a paper feed mechanism.

- A heating device heats the paper to the appropriate forming temperature.

- The heated paper enters the hot press forming area, comprised of aluminum alloy molds. The molds, operated by a hydraulic or pneumatic system, press and form the paper, creating the initial shape of the food tray.

- The formed trays are collected and organized by a box collection mechanism, completing the entire production process.

FAQ

The food container making machine uses high-quality components, resulting in low overall maintenance costs. Troubleshooting is also easy, allowing problems to be quickly identified and resolved.

Yes. By replacing aluminum alloy molds of different specifications, the food container making machine can produce food trays of various sizes and shapes.

The FL-100 has a total power of 5 kW, which is relatively low per unit product. The machine uses an intelligent temperature control system that automatically adjusts the heating power.

Why Choose Foodline Equipment

- Professional technical team

- CE certification

- After-sales service

- Extensive export experience

In addition, we also have food sterilizers. Welcome to consult and get a quote! WhatsApp/Phone: +86 13838385752.