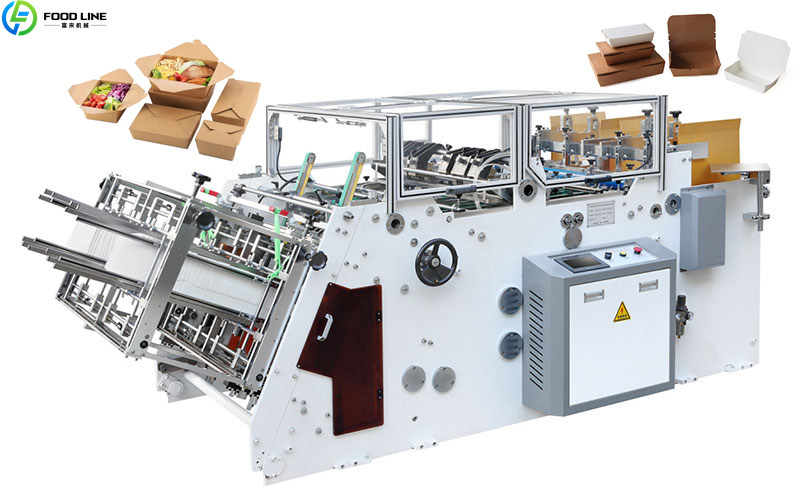

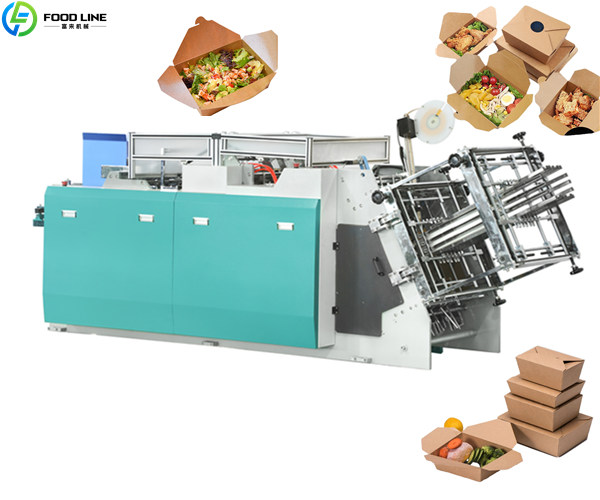

The Lunch box forming machine is an automated machine for producing paper lunch boxes, lunch boxes, food storage boxes, and other containers. This intelligent equipment integrates stamping, servo control, dual-station collaboration, and mold customization. Through fully automated processes, it serves a wide range of fast food chains, central kitchens, food processing companies, and packaging suppliers. Welcome to consult for a quotation! WhatsApp/Phone: +86 13838385752.

Specifications of Paper Box Forming Machine

| Parameter | Specification |

|---|---|

| Model | FL-1600 |

| Paper Weight | 210 – 1000 g |

| Speed | 60 – 360 pcs/min |

| Paper Thickness | 0.3 – 1.5 mm |

| Min. Paper Size | 120 × 120 mm |

| Max. Paper Size | 600 × 500 mm |

| Air Pressure | 0.5 MPa |

| Voltage | 380 V |

| Current | 23 A |

| Total Power | 7.5 kW |

| Frequency | 50 Hz / 60 Hz |

| Machine Weight | 2000 kg |

| Machine Size | 3600×1800×1500 mm |

Paper Food Container Machine Working Principle

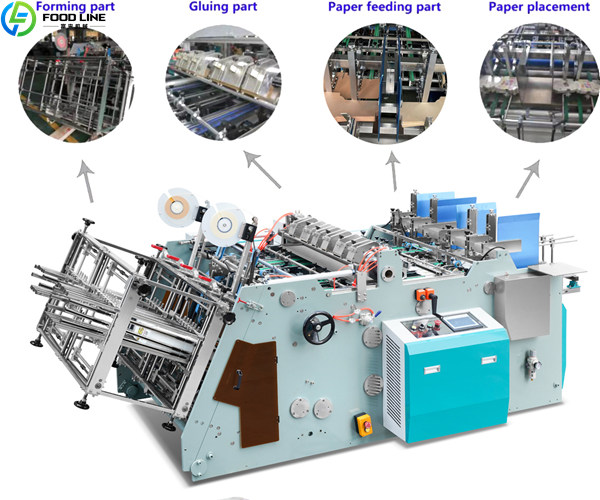

Paper Feed System

The equipment utilizes a vacuum feed mechanism and servo-motor-driven paper feed rollers to feed paper ranging from 210 to 1000g and 0.3 to 1.5mm thick into the processing line.

Dual-Station Stamping Module

The equipment features two independent stamping units, each controlled by a fully servo system. They simultaneously produce the same box shape, with both stations operating simultaneously. No downtime for die changes is required, ensuring continuous production.

Multi-Dimensional Forming

After stamping, the semi-formed box enters the servo-driven folding and shaping module. This module folds, presses, and shapes the sides, bottom, and latch.

Automatic Receiving

After being ejected from the forming station by a pneumatic feeder, the finished lunch box enters a servo-controlled receiving conveyor. This facilitates manual packing and can also be directly connected to an automated packaging line.

Features of Food Box Forming Machine

Dual-station Collaboration

Two sets of stamping and forming units can be pre-configured in the system to accommodate large and small orders, as well as mold changes without stopping the machine. This allows the machine to maintain operation to meet various production needs.

Fully Servo Control

The machine is equipped with servo motors that control core operations such as paper feeding, stamping, folding, and receiving. Each lunch box precisely forms to the desired dimensions, folding angle, and sealing position.

Mold

The paper box forming machine is compatible with a variety of lunch boxes. Molds can change quickly.

Environmentally Friendly

In addition to the optional sealing configuration, the forming process requires no additional adhesives, reducing chemical pollution. Compared to similar equipment, this machine also offers lower energy consumption and quieter noise levels.

Free Quote! WhatsApp/Tel: +86 13838385752.

Food Box Forming Equipment Advantages

Production Capacity

When operating in dual stations, the system can produce 21,600 lunch boxes per hour. Based on an 8-hour day, the daily production capacity exceeds 170,000 boxes. This significantly shortens delivery cycles for peak season orders for chain restaurants or stocking up for major sales on e-commerce platforms, helping customers seize market opportunities.

Cost Reduction

Fully automated production requires only one or two operators. Precision servo press-fitting eliminates the need for pre-opening the boxes, shortening production cycles.

Quality

The lock and folding edges precisely press together by a servo motor, ensuring a high degree of security. Minimal tolerances in length, width, and height are achieved, and the folding angles are uniform, resulting in neat and aesthetically pleasing stacking, enhancing brand image. The optional sealing feature minimizes liquid leakage, meeting the packaging needs of foods such as soups, porridge, and sauces.

FAQ

It supports white cardboard, kraft paper, coated paper, composite paper, etc. Weights range from 210 to 1000g, and thicknesses from 0.3 to 1.5mm.

380V three-phase power and 0.5MPa air pressure are required.

Fully supported. The equipment can integrate with automatic case packers, inkjet printers, shrink wrappers, and other equipment to create a fully automated packaging production line.

The lunch box forming machine has passed CE, ISO9001 and other international certifications.

About Foodline Equipment

- 20 years of industry experience

- After-sales service

- Export experience

- CE certification

Choosing our lunch box forming machine means not only choosing an efficient machine, but also choosing a trustworthy partner. We also offer UV flying laser marking machines. Feel free to contact us for more information! WhatsApp/Phone: +86 13838385752.