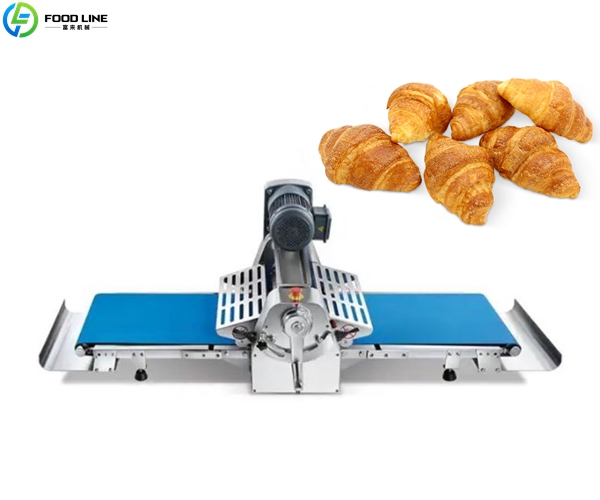

In the baking industry, products such as croissants, Danish pastries, and puff pastry cookies require highly specialized equipment. A puff pastry machine can achieve repeated rolling, even folding, and consistent lamination of the dough. It is an essential piece of equipment for modern bakeries, central kitchens, and food factories.

This equipment is not only suitable for bread lamination processes, but also for the production of biscuits, puff pastries, and frozen dough. It provides businesses with an efficient and stable lamination solution. Contact us to get a quote! WhatsApp/Phone: +86 13838385752.

Industrial Puff Pastry Machine Overview

A puff pastry machine is a specialized food processing machine used for dough rolling and puffing. Multiple rolling and folding processes layer the butter and dough to create a uniform texture. This design results in a crispy exterior and a light interior during baking. Whether it’s a small bakery or a large-scale food processing plant, this equipment can achieve stable mass production. It reduces reliance on manual labor and increases the yield rate of finished products.

Parameters of Puff Pastry Sheeter Machine

| Model | Voltage(v) | Power(kw) | Conveyor(mm) | Nip Roller Spacing(mm) | Rolling Amount(kg) | Dimensions(mm) | Weight(kg) |

| FL-420 | 110/220/380 | 0.75 | 400*1700 | 1-50 | 4 | 855*2020*1285 | 260 |

| FL-520 | 110/220/380 | 0.75 | 500*2000 | 1-50 | 5 | 955*2020*1285 | 300 |

| FL-630 | 110/220/380 | 0.75 | 610*2800 | 1-50 | 6.5 | 1055*3320*1285 | 350 |

| TFL-420 | 110/220/380 | 0.4 | 400*1700 | 1-50 | 4 | 1900*800*700 | 110 |

| TFL-520 | 110/220/380 | 0.75 | 500*2000 | 1-50 | 5 | 2430*880*1230 | 240 |

How a Puff Pastry Machine Works

The working principle of a puff pastry machine is based on continuous rolling and controlled folding. During operation, the dough is fed into the pressing roller system by a conveyor belt, where the rollers stretch the dough to a set thickness. Through repeated rolling, the butter and dough layers gradually form a regular structure. Multiple folds and rollings create a stable multi-layered structure within the dough, providing the foundation for puff pastry in subsequent baking.

Features of Automatic Puff Pastry Making Machine

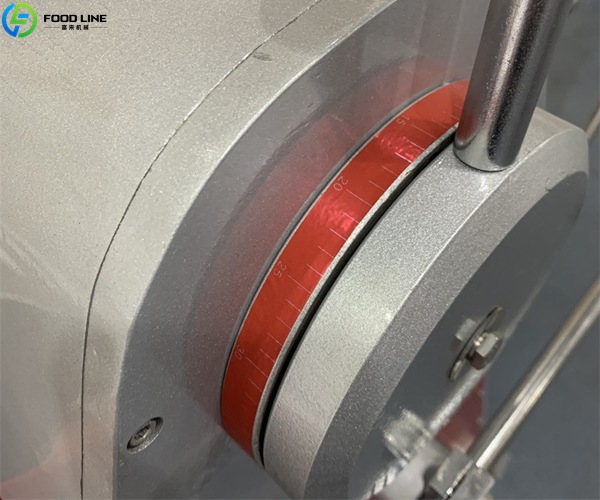

- Rolling Precision: The puff pastry sheeter machine employs a high-precision roller system. The roller spacing is freely adjustable within the range of 1–50mm, ensuring uniform dough thickness and clear puff pastry layers.

- Multiple Models: From tabletop to vertical models, it can meet the diverse production needs of small bakeries, medium-sized central kitchens, and large food factories.

- Conveying System: The extended and widened conveyor belt design ensures smooth dough movement. This design avoids uneven stretching or breakage, improving the success rate of puff pastry.

- Structure: The entire machine features a high-strength structural design. Key components are wear-resistant and durable, suitable for long-term continuous operation.

- Operation: The user-friendly control design allows even novice employees to quickly master the equipment’s operation.

Advantages of Puff Pastry Dough Sheeter

- Efficiency: Puff pastry machines reduce processing time, enable continuous operation, and increase output per unit time.

- Quality: Mechanized production eliminates human error. The equipment ensures consistent dough thickness, weight, and layers, facilitating brand standardization.

- Cost: One puff pastry sheeter machine can replace multiple workers, reducing reliance on manual labor and lowering long-term operating costs.

- Products: Suitable not only for puff pastry but also for puff pastries, Danish pastries, frozen puff pastry dough, and other products.

- Production Line Integration: The equipment can be integrated into existing baking production lines, enhancing overall automation levels.

FAQ

For small stores, the TFL series is recommended. And for medium-sized production, the FL-420 or FL-520 is recommended. For large-capacity needs, the FL-630 is recommended.

Yes. All models support 110V, 220V, and 380V, suitable for use in different countries and regions.

Operators can adjust the roller spacing within a range of 1–50 mm to meet the needs of different puff pastry processes.

Why Choose Foodline Equipment?

- CE Certification

- R&D Team

- After-sales Service

- Export Experience

In addition, you can click to view our bread production line. Puff pastry machines can be integrated into the production line. If you are interested, please contact us for a quote! WhatsApp/Phone: +86 13838385752.