The bagel making equipment is crucial for improving production efficiency and product quality. While handmade bagels retain a certain craftsmanship, their production capacity is limited. With growing market demand for bagels, automated equipment is gradually replacing manual labor, enabling bakeries and catering businesses to achieve large-scale production. For more information, please contact us! WhatsApp/Phone: +86 13838385752.

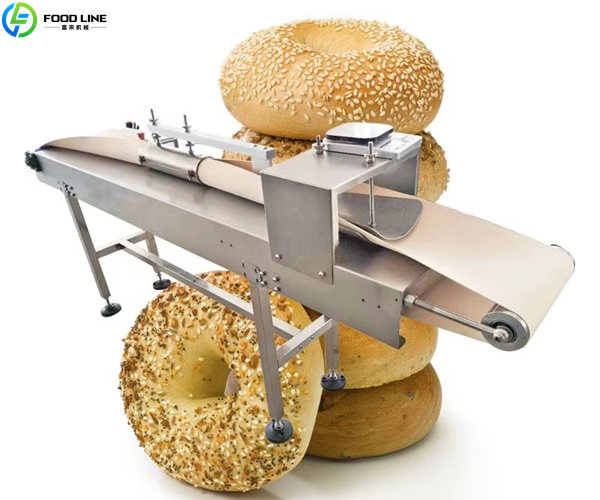

Bagel Forming Machine Overview

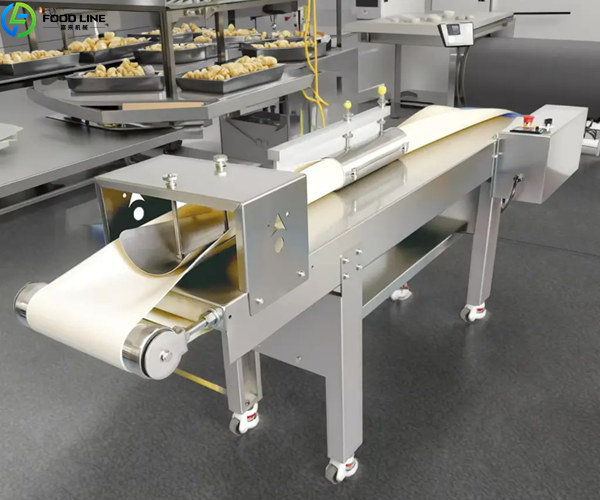

This bagel forming machine features an advanced mechanical design, consisting of an inlet, conveyor belt, control panel, conveyor switch, discharge port, and universal wheels. It can form 2,000 bagels in an hour. The efficient forming process ensures uniform size and a smooth surface, enhancing product quality.

The forming machine can be used alone, with the operator simply placing the dough into the feed port to form it quickly. It can also be connected to a block divider to form a complete production line to meet the needs of different production scales.

Parameters of Bagel Making Equipment

| Specification | Value |

|---|---|

| Product Name | Bagel Forming Machine |

| Model | FL-BG350 |

| Voltage | 220V / 380V |

| Power | 0.55 KW |

| Forming Weight Range | 30-150 g/pc |

| Output Capacity | 2000 pcs/hour |

| Overall Dimensions | 2150*600*1150 mm |

| Packaging Dimensions | 2180*630*600 mm |

| Net Weight / Gross Weight | 125 kg / 150 kg |

| Remarks | One mold included as standard |

Bagel Making Machine Features

Molds

This machine supports custom molds of various sizes to meet diverse customer needs. Adjustable mold sizes are suitable for dough weights ranging from 30-150g.

Molding Results

The finished bagels have uniform size and a smooth surface. High quality standards remain consistent whether operators add the dough manually or use a portioning machine.

Speed Adjustment

The control panel includes a belt speed controller, allowing you to adjust the speed according to production needs and ensure product quality and efficiency.

Operational Design

The machine features a user-friendly design, an intuitive control panel, and a conveyor belt switch, allowing operators to operate easily after simple training.

High Output

The maximum output is 2000 pieces/hour, reducing labor requirements. This reduces labor costs and improves overall production efficiency.

Stable Performance

The optimally designed discharge port ensures fast molding. The weight fluctuation within a mold is only ±10g, ensuring product consistency.

Free Quote! WhatsApp/Tel: +86 13838385752.

Working Principle of Commercial Bagel Making Equipment

The operating principle of a bagel forming machine is based on a combination of mechanical conveying and die forming.

- Infeeding: The operator places the dough into the inlet. Operators can do this manually or connect the system to a block divider for continuous production.

- Conveying: The dough is conveyed by a conveyor belt into the forming die.

- Forming: The die within the machine shapes the dough into uniformly sized, smooth bagel bases.

- Discharging: The machine discharges the formed bagels from the discharge port and sends them to the next process, such as proofing or baking.

Advantages of Bagel Forming Equipment

Production Capacity

Compared to traditional manual operations, bagel making equipment offers higher production efficiency and can meet the demands of large-volume orders.

Product Quality

Uniform molding ensures consistent results, helping companies establish a stable brand image.

Cost Savings

Automated operations reduce reliance on labor and lower production costs.

Customer Satisfaction

Custom molds of various sizes are supported, allowing us to adjust mold specifications to meet individual customer needs.

Mobility and Cleaning

Universal casters on the bottom of the equipment facilitate mobility. The conveyor belt allows for quick cleaning, ensuring food safety and hygiene.

FAQ

The maximum capacity is 2,000 pieces/hour, which can meet the production needs of bakery factories.

Yes. The bagel forming machine operates as a standalone unit or integrates with a portioner and other baking equipment to form a production line.

The dough weight fluctuation range for each mold is within ±10g, ensuring high consistency in the finished product.

About Foodline Equipment

When choosing equipment, the supplier’s strength and service are crucial. Our company offers the following advantages:

- R&D Technology: Our professional technical team continuously optimizes equipment design and performance to ensure our products remain at the forefront of the industry.

- Quality Assurance: Our equipment undergoes extensive testing and is CE-certified before shipment.

- After-Sales Service: We provide installation guidance, operator training, and long-term maintenance support.

- Export Experience: Our equipment has been exported to numerous countries and regions.

If you are looking for an efficient and reliable bagel forming machine, please feel free to contact us. In addition, we also have biscuit forming equipment. WhatsApp/Phone: +86 13838385752.