The cashew nuts are highly sought after for their rich nutritional value and widespread market demand. However, traditional cashew nut processing methods are time-consuming, labor-intensive, inefficient, and difficult to maintain consistent product quality. With the continuous advancement of food mechanization and intelligent processing, cashew nut processing lines have become an ideal choice for many processing plants and investors. They not only ensure high-quality cashew nuts and yield but also reduce labor costs and improve overall production efficiency. Contact us for inquiries! WhatsApp/Phone: +86 13838385752.

Production Line of Cashew Description

This cashew nut processing line is centered around automation, standardization, and intelligence. Combining advanced processes and high-performance machinery, it enables comprehensive cashew nut processing, from raw nut grading to finished product packaging. The modular design enables flexible configuration tailored to business needs. This makes it suitable for both large and medium-sized processing plants.

The entire line encompasses steps such as raw nut grading, steaming, cooling, shelling, screening, drying, peeling, color sorting, and vacuum packaging. This minimizes manual intervention and enhances product quality and safety.

Production Process of Cashew Nut Processing Line

The entire cashew nut production line has a clear process flow, primarily divided into the following steps:

- Raw Material Grading: Cashew nuts of different sizes are graded using a grader to ensure that subsequent processes are compatible with shelling equipment of varying nut diameters.

- Steaming and Natural Cooling: Graded cashew nuts are steamed to soften the shells. They are then naturally cooled for easier shelling.

- Automatic Shelling: The raw nuts are fed into an automatic shelling machine, using different models of shellers for different nut sizes. Adjustable gaps ensure efficient shelling.

- Shell-Kernel Separation: After shelling, the kernels are separated from the shells by screening and wind separation equipment. The shells can be further extracted for oil. While the kernels are fed to the next process.

- Secondary Shelling and Manual Sorting: Nuts that have not been fully shelled or whose shells are stuck to the kernels undergo secondary processing using centrifuges and screening machines, supplemented by manual sorting.

- Kernel Drying and Humidification: After drying, the kernels are treated in a humidifier to facilitate peeling.

- Peeling and Color Sorting: Kernels that remain partially shelled are sorted again by color sorting machines or by hand to obtain clean, white kernels.

- Secondary Roasting and Seasoning: Cashew kernels can be further roasted or seasoned to create a variety of flavors.

- Packaging: Finally, they are packaged in a vacuum packaging machine to ensure product freshness and safety.

Free Quote! WhatsApp/Tel: +86 13838385752.

Cashew Nut Production Line Main Equipment Parameters and Introduction

Elevator

- Dimensions: 3.5 × 0.51 × 0.5 m

- Material: Carbon steel

- Function: Used for continuous conveying of raw fruit. Equipped with a feed hopper to ensure stable feeding of the grader.

- Advantages: Smooth operation, simple structure, easy maintenance, and effectively reduces manual labor.

Cashew Grading Machine

- Output: 1000–1200 kg/h

- Power: 3 kW

- Voltage: 380 V, 50 Hz

- Dimensions: 10 × 1.6 × 2.5 m

- Weight: 1000 kg

- Material: Carbon steel

- Function: Sorts cashew nuts into 5–6 grades.

- Purpose: Different-sized nuts are steamed and shelled separately, improving kernel integrity.

Cashew Nut Steaming Machine

- Output: 1000-1200 kg/h

- Power: 0.75 kW

- Voltage: 380 V

- Frequency: 50 Hz

- Main Unit: Steamer

- Elevator Material: Carbon Steel

- Dimensions: 2 x 1 x 2.8 m

- Function: Steams cashew nuts at high temperatures to soften the shells.

- Advantages: Precise temperature control and uniform heating facilitate subsequent shelling and minimize kernel damage.

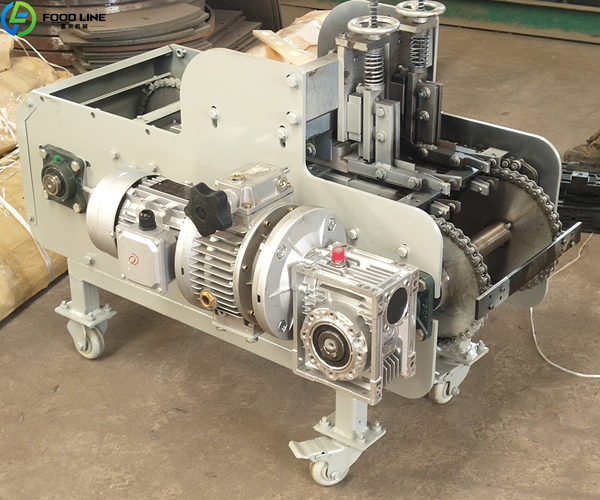

Automatic Shelling Machine

- Applicable fruit sizes: Large, medium, and small, with adjustable gap.

- Power: Approximately 3–4 kW

- Voltage: 380 V

- Production capacity: Approximately 250–300 kg/h (standalone unit)

- Features: Automatically hulls fruit based on size, reducing breakage.

- Advantages: Clean hulling, stable production capacity, and significantly improved kernel integrity.

Shell and Kernel Screening and Pneumatic Separation System

- Power: 1.5–2.2 kW

- Function: Multi-layer screening and air separation effectively separate shells, kernels, and unopened fruit, improving purity.

Secondary Shelling Machine of Cashew

- Output: 80–100 kg/h

- Dimensions: 1.45 × 0.85 × 1.2 m

- Shell opening rate: 90%, breakage rate: less than 5%-10%.

- Function: Rapid peeling, keeping the kernel white and intact.

Color Sorter

- Capacity: ≥300 kg/h

- Power: 2.5 kW

- Voltage: 220 V/380 V

- Function: Automatically identifies color and rejects kernels with shells, skins, or defects.

- Benefits: Improves product consistency and ensures finished products meet export standards.

Vacuum Packaging Machine

- Dimensions: 1.2 x 0.7 x 0.9 m

- Power: 4 kW

- Equipped with 8 mold sets.

- Function: Multiple packaging options available, extending product shelf life.

Free Quote! WhatsApp/Tel: +86 13838385752.

Features of Cashew Nut Machines

- High Production Capacity: The entire line boasts a production capacity of 1,000 kg per hour, making it suitable for large-scale processing plants.

- Intelligent: Automated hulling, screening, peeling, color sorting, and packaging processes are highly intelligent, reducing manual intervention.

- Modular Configuration: Flexible equipment combinations allow for customized adjustments.

- Food Safety: All product contact parts are constructed of stainless steel or food-grade materials to ensure hygienic safety.

- Energy Saving and Environmental Protection: The equipment consumes low energy, and its steam heating method is energy-efficient and efficient.

- Easy Maintenance: The elevator, dryer, and peeler are all easily cleaned, minimizing downtime.

Advantages of Equipment for Cashew Nuts

- Reduced Labor Costs: Automation replaces numerous manual operations, reducing labor requirements.

- Improved Product Quality: Precise grading and efficient shelling reduce breakage and increase kernel integrity.

- Stable and Reliable: The production line operates stably, with low equipment failure rates and simplified maintenance.

- Flexible Scalability: Customizable functionality and capacity expansion are possible based on customer needs.

- Strong Market Competitiveness: Standardized production processes ensure product consistency, meeting the stringent requirements of domestic and international markets.

FAQ

Yes. The machine’s interior is smooth and resists residues like peels and oil. Routine maintenance requires only regular inspections and simple operations, minimizing manual labor.

Yes. Cashew nut shells can be used to extract cashew oil using an oil press. This not only reuses the resource but also increases its added value.

We can provide flexible production line configurations based on the customer’s factory space, production capacity requirements, and budget. Whether you’re a small factory or a large enterprise, we can find a suitable solution.

Yes. During the final stages of baking, various seasonings are added to the recipe. This allows us to tailor the flavor profile to meet the preferences of consumers in different markets.

Foodline Machinery-Your Trust Partner

- Extensive Experience: We have many years of experience in the R&D and manufacturing of food processing machinery, particularly in cashew nut processing machines.

- Quality Assurance: All equipment is made of carefully selected materials and meets international food safety standards.

- Customized Service: We offer customized solutions tailored to your site, production capacity, and budget.

- Comprehensive After-Sales Service: We provide remote installation and commissioning, operator training, and long-term maintenance support.

- Global Application Cases: Our cashew processing lines are widely used in countries and regions such as Africa, Southeast Asia, and South America. They have received unanimous praise from our customers.

Investing in an efficient cashew nut processing line not only boosts production efficiency but also gives you a competitive edge in the market. Whether you’re new to cashew processing or looking to upgrade your existing line, we can provide you with the optimal solution. Choosing us means choosing a trustworthy partner! Welcome to consult and get a quote! WhatsApp/Phone: +86 13838385752.