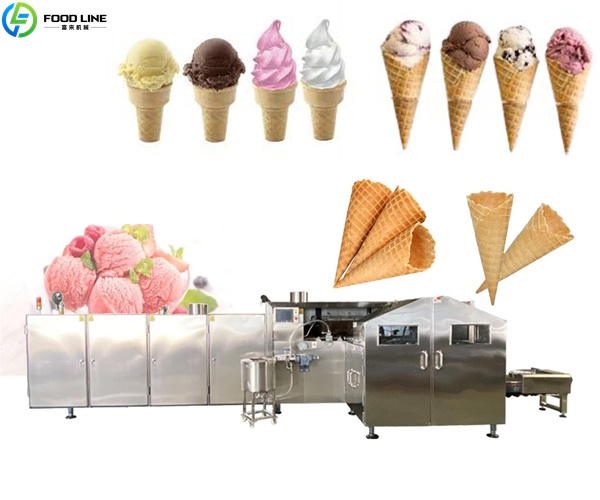

As an essential container for ice cream, the ice cream cone continues to see increasing demand. To meet this market demand, many companies are investing in efficient ice cream cone production lines. These lines not only improve production efficiency but also ensure the quality of the ice cream cones. Inquire for a quote! WhatsApp/Phone: +86 13838385752.

Ice Cream Cone Lines Overview

The ice cream cone production line is a fully automated facility designed for producing cones of various shapes. It automates the entire process, from raw material mixing and slurry conveying to baking, rolling, cooling, and packaging. This automation reduces the need for manual operation. This ensures the quality of the cones, meeting modern food processing standards.

Parameters of Ice Cream Cone Production Line

Baking Equipment

| Model | Production Capacity (pcs/h) | Angle | Suitable for Cone Length | Baking Plate Size (MM) |

|---|---|---|---|---|

| FL117 x 2-40A | 10500~12000 | 14°~34° | ≤125 MM, ≤145 MM | 280×240, 320×240 |

| FL107 x 2-40A | 9500~11000 | 14°~34° | ≤125 MM, ≤145 MM | 280×240, 320×240 |

| FL85 x 2-36A | 7500~9000 | 14°~34° | ≤125 MM, ≤145 MM | 280×240, 320×240 |

| FL75 x 2-30A | 6500~8000 | 14°~34° | ≤125 MM, ≤145 MM | 280×240, 320×240 |

| FL53 x 2-20A | 4500~6000 | 14°~34° | ≤125 MM, ≤145 MM | 280×240, 320×240 |

| FL37 x 2-16A | 3000~4000 | 14°~34° | ≤125 MM, ≤145 MM | 280×240, 320×240 |

| FL159-24B | 4500-6000 | 14°~34° | ≤190 MM, ≤220 MM | 210×240, 240×240 |

| FL139-24B | 4000-5500 | 14°~34° | ≤190 MM, ≤220 MM | 210×240, 240×240 |

| FL107-24B | 3500-5000 | 14°~34° | ≤190 MM, ≤220 MM | 210×240, 240×240 |

| FL71-20B | 2000-3500 | 14°-34° | ≤190 MM, ≤220 MM | 210×240, 240×240 |

| FL61-16B | 1800-3000 | 14°~34° | ≤190 MM, ≤220 MM | 210×240, 240×240 |

| FL45-16B | 1200-2200 | 14°~34° | ≤190 MM, ≤220 MM | 210×240, 240×240 |

Mixing and Conveying Equipment

| Equipment Type | Technical Parameter | Details |

|---|---|---|

| Mixer | Mixing Type | Turbine type |

| Device Configuration | Electrical control box, batter outlet (2 inch ball valve) | |

| Bottom Design | Tilting design for faster and adequate outflow | |

| Structure | Inner liner, insulation layer, protective shell | |

| Material | Stainless steel 304 | |

| Volume | 90L/190L/270L/320L | |

| Voltage | 220V/380V/415V/440V | |

| Rated Power | 3.0 KW/4.0 KW/5.5 KW | |

| Frequency | 50 HZ/60 HZ | |

| Batter Trolley | Device Configuration | Electrical control box, batter outlet (2 inch ball valve) |

| Bottom Design | Inclined type for better and faster batter flow | |

| Structure | Composed of a support frame and mixing barrel | |

| Material | Stainless steel 304 | |

| Volume | 280L |

Free Quote! WhatsApp/Tel: +86 13838385752.

Egg Cone Production Line Equipment Description

- Mixing drum: Used to mix the ingredients for making sugar cones. The mixing drum is made of 304 stainless steel.

- Slurry pump: Pumps the mixed slurry from the mixing drum and delivers it to the slurry delivery vehicle.

- Slurry delivery vehicle: Made of 304 stainless steel, it is primarily used for storing and transporting slurry.

- Oven: Featuring an energy-saving design, it efficiently bakes the sugar cone batter. The oven is gas-heated and features a precise temperature control system to ensure perfect baking.

- Operation panel: The touchscreen interface makes the equipment easy to operate. Users can adjust production parameters as needed.

- Feed drum: Stores the slurry and delivers it to the baking trays via the feed pump. This equipment is made of 304 stainless steel.

- Roller: Automatically rolls the baked sugar cone wrappers.

- Endless conveyor: Transports the baked sugar cones.

- Metal detector: Detects metal to ensure the product is free of impurities. If metal is detected, the system automatically removes it.

- Paper sleeve application device: Automatically and precisely applies paper sleeves to the sugar cones. Cup rim arrangement device: Arranges the “V” openings of the cones to ensure neat arrangement.

- Counting device: Allows you to set the number of stacked cones as needed.

Sugar Cone Production Line Production Process

- Mixing and Blending: Add the required ingredients (such as flour, sugar, and oil) in the specified proportions into a mixing bowl. Stir the mixture to form the sugar cone batter.

- Slurry Delivery: The slurry pump transports the slurry to the slurry delivery vehicle to ensure supply.

- Baking: The slurry is baked in an oven to produce the sugar cone wrappers. During the baking process, the temperature and baking time can adjust according to product requirements.

- Rolling and Forming: The baked sugar cone wrappers are automatically rolled by a rolling machine, and the formed sugar cones are transported to the next process via an endless conveyor belt.

- Cooling: The sugar cones are cooled on a cooling belt to ensure they retain their shape before packaging.

- Packaging and Counting: The automatic packaging system groups and packages the sugar cones according to a set counting device.

Features of Ice Cream Cone Making Machines

- Automation: This production line utilizes automated processes, reducing manual intervention and ensuring efficient production.

- Energy Saving: The gas-heated oven utilizes heat efficiently, reducing energy consumption and meeting environmental requirements.

- Product Diversification: By changing the forming unit, the production line can produce a variety of cone shapes. The toaster can produce egg rolls, bowl-shaped cups, natural-rimmed cones, flat cones, and more, meeting diverse needs.

- Control: A touchscreen control panel allows for adjustable parameters to ensure precision at every step.

Free Quote! WhatsApp/Tel: +86 13838385752.

Advantages of Ice Cream Cone Production Line

- Efficiency: The fully automated production line improves production efficiency, reduces labor costs, and reduces operational errors.

- Quality: The automated control system ensures highly consistent quality of the cones, meeting standards for shape, taste, and appearance.

- Maintenance: The touchscreen operation panel makes the production line easy to operate and maintain.

- Production Capacity: The production line equipment can adjust to meet production needs of varying scales, depending on product specifications and requirements.

FAQ

This line is suitable for producing a variety of cone types, including egg rolls, bowls, natural-rimmed cones, and flat cones.

The production capacity is 1,200-12,000 pieces per hour, depending on the specifications of the oven.

The line uses a touchscreen interface, making operation simple and intuitive. Even inexperienced operators can quickly master it.

We can customize the production line according to customer’s needs, including different oven specifications, forming devices, etc.

Why Choose Foodline Equipment

- High-quality equipment

- After-sales service

- R&D team

If you want to get more equipment parameters and details, please contact us! In addition, we also have egg roll-forming machines. Get a quote! WhatsApp/Phone: +86 13838385752.