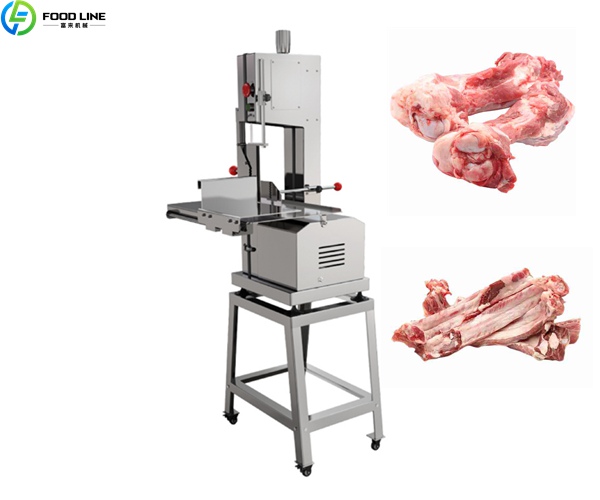

In the meat processing industry, efficient and stable cutting equipment is the key to improving production efficiency and product quality. The Model 310 Bone Saw is a commercial benchtop bone saw. It provides ample operating space for cutting large meat products, making it ideal for commercial kitchens and meat processing plants. It efficiently handles beef and pork bones, large cuts of meat, and other items, making it a key piece of equipment in the cutting process. Welcome to consult! WhatsApp/Phone: +86 13838385752.

Meat Cutting Band Saw Specifications

| Product Parameters | Details |

|---|---|

| Product Name | FL-B310 |

| Motor Power | 2200W (Pure Copper) |

| Rated Voltage | 220V (Customizable) |

| Cutting Speed | 300m/min |

| Saw Blade Model | 1980mm |

| Cutting Height | 0~310mm |

| Cutting Width | 5~190mm |

| Net Weight | 55kg |

| Platform Size | 610×430mm |

| Body Size | 630×530×1050mm |

Features of Bone Saw Machine

- Excellent Cutting Performance: The combination of a 310mm cutting height and a 190mm cutting width easily handles large meat products. Whether it’s whole ribs, large pieces of frozen meat, or even hard, bony ingredients, it can be cut to meet diverse processing needs, helping businesses expand their product range.

- Comprehensive Safety Design: Equipped with an emergency stop/switch, the machine can be quickly shut down in the event of an emergency, ensuring safe operation. The double-push plate design ensures stable feeding of ingredients and prevents hands from coming close to the saw blade, reducing the risk of injuries and ensuring operator safety.

- Practical Details: The motor’s cooling holes ensure adequate heat dissipation during extended operation, reducing malfunctions caused by overheating and extending the lifespan of the machine. The saw blade adjustment knob allows precise adjustment of the blade’s tension and position based on the hardness of the food and the desired cutting surface, ensuring consistent cutting results. The stainless steel workbench is rust-resistant and easy to clean, meeting food processing hygiene standards and reducing the risk of bacterial growth.

Bone Sawing Machine Advantages

- Improved Production Efficiency: High-efficiency cutting capabilities shorten meat processing time, significantly increasing the amount of meat processed per unit time compared to traditional manual cutting or inefficient equipment.

- Stable and Reliable Performance: Designed specifically for meat processing, the machine features a sturdy construction, low vibration and noise during operation, and a stable cutting process. Over long-term use, the machine has a low failure rate, minimizing the impact of downtime and maintenance on production schedules, ensuring continuous production and reducing operational costs.

- Manageable Maintenance Costs: The stainless steel (or high-quality carbon steel) machine body is durable, corrosion-resistant, and wear-resistant. Key components are designed for easy access and replacement; for example, changing the saw blade is quick and easy with a simple knob. Daily cleaning is simple, requiring only wiping the workbench and machine body, making maintenance easy and cost-effective, saving companies long-term operating expenses.

Customer Success Cases

Case 1: A factory in the United States specializes in American-style smoked meat products. Previously, the plant used traditional manual bone saws for cutting. It was not only inefficient and resulted in uneven cuts, but also placed employees under intense labor for long periods. The introduction of a 310 bone saw resolved the production bottleneck. The smoothness of the cut surface has been significantly improved, reducing waste during subsequent processing, allowing for more uniform marinating and smoking, significantly improving the quality of the finished product, and boosting customer satisfaction. Today, this equipment has improved employee satisfaction, continued to help the company expand production and increase efficiency, and steadily increased market share.

Case 2: A Sydney-based restaurant chain’s central kitchen needs to provide large quantities of pre-cut meat ingredients to its restaurants daily. The brand has introduced two bone saws. The stable performance and cutting capacity of the 310 bone saws ensure highly consistent ingredient specifications. Both the length of the meat segments and the size of the cuts meet the standards for each restaurant’s menu. This not only ensures consistent taste for customers but also optimizes food delivery efficiency. Furthermore, the equipment’s easy-to-clean and easy-to-maintain design meets the stringent food hygiene management requirements of central kitchens.

Why Partner With Us?

At Foodline Machinery, we not only manufacture exceptional equipment, but we’re also committed to building lasting partnerships. Our strengths lie in:

- 20 Years of Industry Experience: Deep expertise in mechanical equipment processing technology.

- End-to-End Custom Engineering Solutions: A dedicated R&D team provides tailored system design and complete production line integration services. Custom manufacturing capabilities meet unique operational needs.

- Technical Support: 24/7 multilingual customer service, on-site installation and training programs, and preventive maintenance program services.

- Comprehensive Certifications: CE, ISO 9001, and food safety compliance certifications, regular third-party quality audits, and environmental management system certifications.

We don’t just sell machines; we provide complete processing solutions. These solutions are backed by years of experience and a deep commitment to our partners’ success. Contact us today to speak with one of our solutions experts. WhatsApp/Phone: +86 13838385752.