Paper food containers are essential in the food service industry. They’re environmentally friendly and convenient. A high-performance paper food container machine is key to ensuring efficient, high-quality production. Contact us today! WhatsApp/Phone: +86 13838385752.

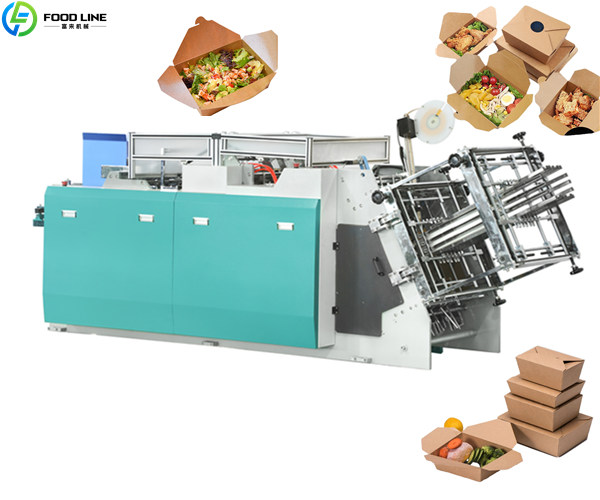

Overview of Food Box Forming Machine

The paper food container machine is a specialized machine for producing paper lunch boxes. It integrates multiple key components, including paper feeding, adjustment, gluing, forming, finished product collection, and counting. It precisely completes the entire production process from paper to various paper food containers. The machine can produce a variety of box shapes, including hamburger boxes, boat boxes, French fry boxes, and takeout boxes. This provides strong production support for the catering industry and related food packaging companies.

Parameters of Lunch Box Forming Machine

| Model | FL-1200 |

|---|---|

| Paper Weight | 210–1000 g |

| Speed | 30–120 pcs/min |

| Paper Thickness | 0.3–1.5 mm |

| Min. Paper Size | 120 × 120 mm |

| Max. Paper Size | 600 × 500 mm |

| Air Pressure | 0.5 MPa |

| Voltage | 380 V |

| Current | 12 A |

| Total Power | 4.5 kW |

| Frequency | 50 Hz / 60 Hz |

| Machine Weight | 1403 kg |

| Machine Size | 3500 × 1350 × 1500 mm |

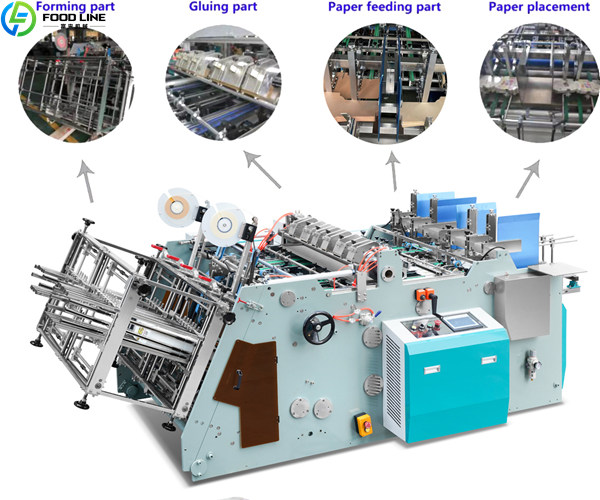

Features of Food Container Making Machine

Structure

- The paper food container machine boasts a sturdy structure, maintaining stability even under long-term, high-load production. It’s less prone to loosening and other issues, ensuring reliable production.

- The high-quality equipment effectively reduces malfunctions during production, improving efficiency and stability.

Performance

- This machine is quiet, creating a pleasant production environment. It reduces noise disturbances to production personnel and improves work comfort.

- It can flexibly adjust various machine parameters to meet specific production requirements, ensuring that paper food containers meet production requirements.

- The gluing unit evenly applies glue, ensuring a perfect adhesion.

- The forming unit precisely shapes paper into the desired box shape.

- The finished product collection unit collects finished products in an orderly manner, facilitating subsequent sorting and packaging.

- The counting unit accurately counts production quantities, facilitating production management and inventory statistics.

Box Types

- Paper food container machines can produce a wide variety of box types.

- Hamburger boxes provide convenient packaging, ensuring easy portability and effectively protecting the burger’s shape.

- Ship boxes are commonly used to hold foods like fried chicken and French fries. Their shape allows for secure storage and convenient eating.

- French fry boxes hold fries securely and provide easy access.

- Takeout boxes protect food during transport and prevent spills.

Free Quote! WhatsApp/Tel: +86 13838385752.

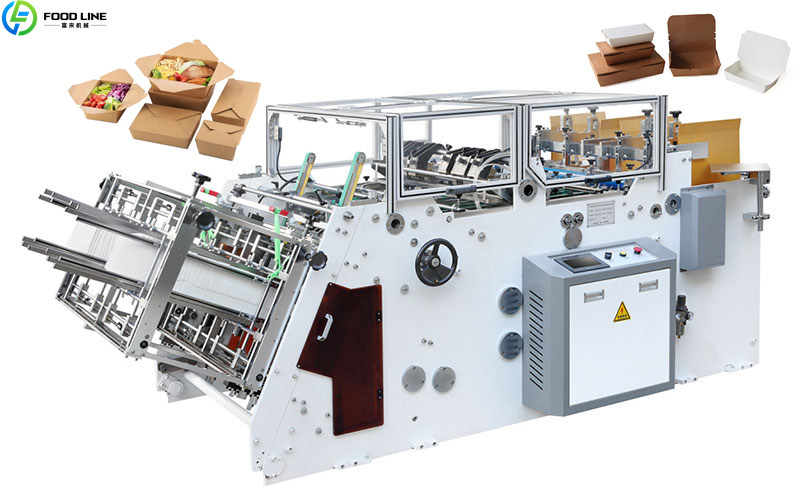

Advantages of Paper Food Container Machine

High Production Efficiency

- The paper food container machine’s efficient production capacity enables it to produce a greater number of paper food containers in a short period of time. This enables businesses to fulfill orders more efficiently, reduce delivery times, and enhance theircompetitiveness.

- This increased production efficiency can also reduce production costs, such as labor costs and equipment wear and tear.

Stable Quality

- Due to the machine’s high quality and sturdy structure, the production process ensures the high quality of all paper food containers.

- The containers are precisely dimensioned and securely bonded. This enhances product reputation and competitiveness.

Functionality

- This machine features multiple key production units and is fully functional. It can accommodate production needs for a variety of box shapes and paper specifications.

- Whether adjusting to paper weight, thickness, or paper size, the machine can accommodate these needs through its built-in adjustment units.

FAQ

The machine requires paper weight between 210 and 1000g. Paper thickness between 0.3 and 1.5mm. The minimum paper size is 120-120mm. The maximum paper size is 600-500mm.

The food container box making machine has a production speed of 30-120 pieces/min. Companies can adjust the speed based on their own production needs and the actual conditions of the paper material.

The equipment requires an air pressure of 0.5 MPa to ensure normal operation.

The total power of the device is 4.5 kW, and the frequency is 50 Hz/60 Hz. The energy consumption is within a reasonable range.

Customer Success Stories

Case 1: A US restaurant company has a high demand for paper food containers, such as hamburger boxes and French fry boxes. They purchased our equipment to address high labor costs. Using the equipment has significantly improved their efficiency.

Case 2: A Mexican company primarily supplies paper food containers to various catering businesses. Due to diverse market demand, the company frequently changes box shapes and paper specifications. The previous equipment used had poor adaptability, and each change required significant time-consuming adjustments, impacting production efficiency and product quality. The introduction of a paper food container machine allows for quick adjustments, significantly improving production efficiency.

Why Choose Foodline Equipment

- R&D and production capabilities

- After-sales service system

- Market reputation and customer trust

In addition, we also have other models of paper box forming machines. Welcome to consult for information and quotes! WhatsApp/Phone: +86 13838385752.