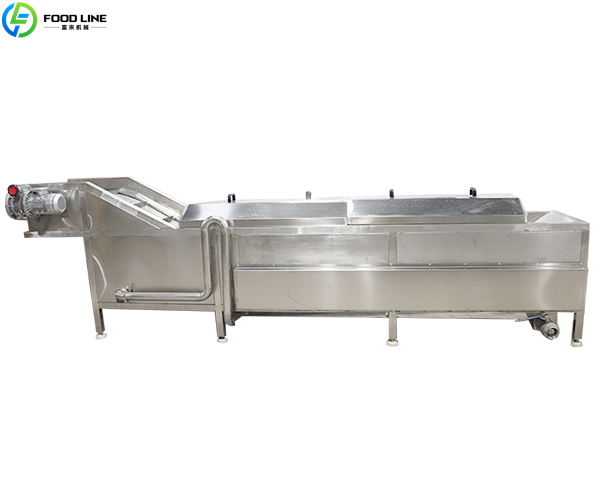

Potato blanching machines play a vital role in the production of potato snacks and frozen foods. Blanching is a thermal treatment process. Potatoes briefly cook in hot water or steam and then quickly cooled. This step helps inactivate enzymes, preserve color and texture, and prepare the potatoes for subsequent processing, such as frying or freezing. Industrial blanching machines are usually used in potato chip production lines, French fry production, dehydrated food, etc. If you want to know more information, don’t hesitate to get in touch with us. WhatsApp/Phone: +86 13838385752.

Parameters of Blanching Machine

| Model | FL-B02 |

|---|---|

| Capacity | 300kg/h |

| Weight | 300kg |

| Dimension | 2500*1100*1300mm |

| Power | 60kw |

Features of Potato Blanching Machines

Potato blanching machines are designed with automation, hygiene and durability in mind. Here are the main features common to these machines:

- Conveying system: Equipped with a mesh belt or chain conveyor, the potato slices steadily convey to the machine.

- Water circulation system: The smart design includes water filtration and circulation systems to reduce overall water consumption.

- Overflow and impurity removal: The float filter and overflow trough automatically remove surface starch, foam, and small potato particles.

- Design: The machine can easily integrate into a complete processing line, including washing, cutting, frying, and cooling systems.

These features ensure stable operation and improved efficiency even in long-term production.

Advantages of Using Our Potato Blanching Machine

- Quality: The blanched potatoes have uniform color, texture, and taste.

- Output: Our machines are available in different outputs for you to choose from.

- Operating costs: Energy-saving heating system and water circulation system reduce expenses.

- Maintenance requirements: The machine is easy to clean and maintain with its stainless steel construction and easy-access panels.

FAQ

French fries, potato chips, diced potatoes and pre-cooked frozen potatoes can all be blanched efficiently.

Yes. It can also be used to process peanuts, vegetables, fruits and meat products, etc.

Of course. Our machines are modular in design and can be connected with washing, slicing, frying and packaging units.

Yes, we provide remote training as well as online assistance 24/7.

Customer Success Stories

Case 1: Maple Valley Snacks, based in Canada, specializes in producing locally flavored potato chips. Previously, they used a traditional drum washing method, which was slow, water-intensive, and left a high level of sediment on the potato surface, affecting the quality of the slices. After comparing manufacturers, the factory installed a fully automatic potato rinsing machine equipped with a high-pressure spray and a circulating water filtration system. Since the start of production, the system has significantly improved cleaning efficiency. It reduces sediment residue, minimizes slicer blade wear, and makes the product appearance cleaner and more uniform. Company officials say this equipment not only saves labor and water costs but also helps them easily pass food safety audits, enhancing the brand’s competitiveness in the North American market.

Case 2: A processing plant in northern France that supplies frozen French fries to restaurant chains processes hundreds of tons of potatoes daily. Due to the high volume and rapid processing speed, the previous manual pre-washing method struggled to maintain quality, resulting in some finished fries with black spots or mud stains on their surfaces, impacting export quality. The introduction of an industrial-grade potato rinser significantly improved mud removal and surface cleanliness through its dual-cleaning process of air bubbles and sprays, while also minimizing damage to the potato skin. The plant stated that the equipment has helped them gain access to more high-end European restaurant supply chains.

Why Choose Our Company for Potato Blanching Machine?

Our company has 20 years of experience in the field of machinery and equipment. It is a trusted supplier of potato blanching machines in the foreign market. Customers from many countries choose us for the following reasons:

- Professional technology: We provide tailor-made solutions for small, medium and large food processing companies.

- Quality assurance: The machines are strictly tested and meet CE and ISO standards.

- Flexible customization: Products are customized according to customer needs.

- Global support: Our after-sales network ensures fast delivery and technical support worldwide.

- Complete production line design: We not only provide blanching machines, but also washing machines, cutting machines, frying systems and packaging equipment.

Choose us and let us be your loyal partner! WhatsApp/Phone: +86 13838385752.