The food safety is a top priority in the food industry. In food processing and packaging, efficient and harmless food sterilization is a key issue. Ultraviolet food sterilizers are a new type of sterilization equipment. They offer high efficiency, environmental friendliness, and no chemical residue. They have become the preferred equipment for many food processing companies. If you are interested, please feel free to consult! WhatsApp/Phone: +86 13838385752.

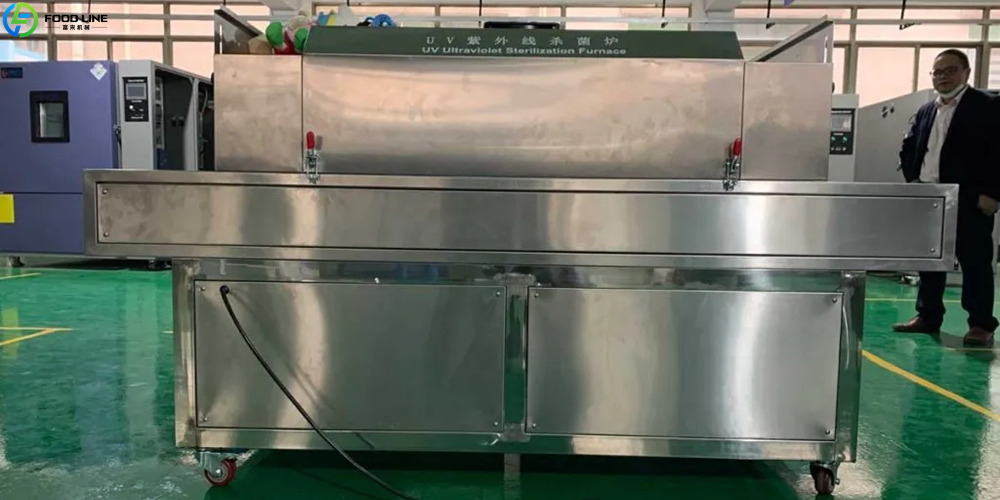

Overview of Food UV Sterilizer

A UV food sterilizer utilizes ultraviolet radiation to sterilize and disinfect food, prepared foods, and water. It effectively and rapidly kills bacteria, viruses, mold, and other microorganisms on food surfaces and in packaging materials. It is widely used in food processing, packaging, beverage production, and other processes to ensure food hygiene and safety.

Parameters of Ultraviolet Food Sterilizer

| Parameter | Specification |

|---|---|

| Total Equipment Length | 2000 mm |

| Working Zone Length | 1000 mm |

| Feeding Zone Length | 500 mm |

| Discharging Zone Length | 500 mm |

| Entrance / Exit Height | 200 mm |

| Conveyor Belt Width | 500 mm |

| Conveyor Belt Height (from floor) | 750 ±20 mm |

| Number of UV Lamps | 16 |

| Power per UV Lamp | 20 W |

Working Principle of UV Food Sterilizer Machine

The working principle of a UV food sterilizer is based on the bactericidal effect of ultraviolet radiation. The germicidal wavelength of ultraviolet radiation is primarily concentrated between 200 and 300 nm, with the 253.7 nm wavelength having the strongest bactericidal effect. When bacteria, viruses, and other microorganisms in water or air pass through the UV radiation zone, the UV rays can penetrate the cell membranes and nuclei of the microorganisms. Destroy its DNA or RNA molecular bonds, thereby losing its activity and achieving a bactericidal effect.

Features of UV Food Sterilizers

Highly Efficient Sterilization

Ultraviolet light effectively kills a wide range of bacteria, viruses, and molds in a short period of time. Sterilization takes only seconds to minutes.

Pollution-Free

UV sterilization uses no chemicals, leaving no harmful chemical residues and harming the environment.

Applications

This UV food sterilizer is suitable for sterilizing prepared foods, beverages, dairy products, and other foods, as well as water disinfection.

Equipment Stability

Crafted from 304 stainless steel, this equipment ensures long-term stable operation. It is corrosion-resistant and heat-resistant, extending its service life.

Operation

The UV food sterilizer is easy to operate. Simply press a button to automatically complete the sterilization process, eliminating manual intervention.

Free Quote! WhatsApp/Tel: +86 13838385752.

Advantages of Ultraviolet Sterilization Machine

No Chemical Residue

UV sterilization produces no harmful chemical residues, ensuring food purity and safety.

Efficient

The UV sterilizer sterilizes food quickly, allowing it to process large quantities of product in a short period of time, improving production efficiency.

Energy-Efficient

Compared to traditional thermal sterilization methods, UV sterilization consumes less energy. This design reduces energy consumption and operating costs.

Safe Operation

The UV lamps within the UV sterilizer are specially designed to effectively prevent UV leakage and ensure operator safety.

Maintenance

The equipment is rationally designed and simple to maintain. The lamps are easily replaced, reducing ongoing operating costs.

Ultraviolet Sterilization Furnace Application Areas

- Food processing industry

- Beverage, dairy product, and health product processing

- Chinese herbal medicine, winemaking, and other food processing

- Hospitals and other places with high hygiene requirements

FAQ

UV sterilization is highly effective, killing most bacteria, viruses, and molds, especially in the treatment of food, beverages, and water. Different types of bacteria and viruses require different killing times. Sterilization is typically completed within a few seconds to a few minutes.

UV sterilizers are suitable for a wide range of food types, including prepared foods, bread, beverages, and dairy products. Any food requiring sterilization can be treated in a UV sterilizer.

UV sterilization has no side effects on food and does not alter its taste, color, or nutritional content. Because no chemicals are used, food quality is preserved.

No, it doesn’t require complex maintenance. Maintaining the equipment primarily involves regular cleaning of the UV lamp and internal components, and checking that the lamp is functioning properly. The equipment itself is very durable and requires minimal maintenance.

About Foodline Machinery

Choosing us offers the following benefits:

- Quality Assurance: This device is CE-certified.

- Customization: We offer customized services tailored to your needs.

- After-Sales Service: We provide comprehensive pre-sales, in-sales, and after-sales support.

Ultraviolet food sterilizer is a safe disinfection technology widely used in modern food processing. Choosing us ensures you receive high-quality UV sterilization equipment and a trusted partner. We also have labeling machines. Welcome to consult! WhatsApp/Phone: +86 13838385752.