A cookie factory in the United States sells large cookies and healthy cereal crackers. With their products now available in chain supermarkets, their existing small-batch production methods were no longer able to meet demand. Low production line efficiency, inconsistent product specifications, and labor costs hindered the brand’s growth. After evaluating several companies, the owner, Mr. David Miller, chose our fully automated cookie production line.

David Miller‘s comment: “Of the biscuit production line manufacturers we discussed, Foodline Machinery’s line best met our requirements. Their product manager thoroughly analyzed our product recipe and process, particularly the characteristics of our dough containing chocolate and nuts. We provided a customized solution. The new line has exceeded our expectations since its commissioning. And its portioning and forming technology preserves the handmade texture of our dough, while the baking process maintains the biscuits’ color. This line not only solves our production capacity issues but also protects our brand reputation.”

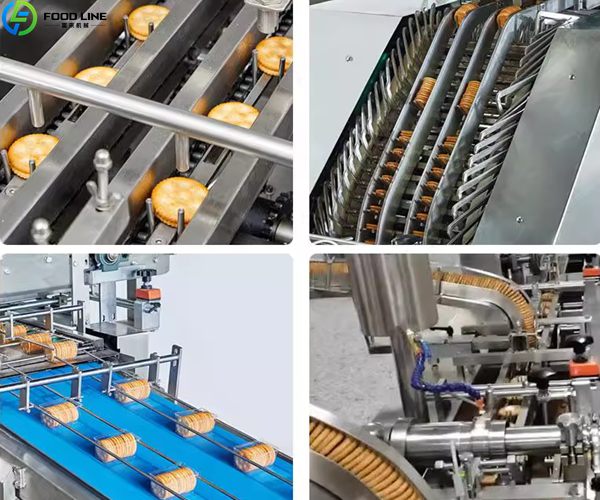

Biscuit Production Line Workflow

- Loading and Mixing: The system automatically feeds the blended flour, oil, sugar, and other ingredients into the mixer for mixing.

- Rolling and Forming: The mixed dough is rolled into dough sheets by a dough sheeter and then formed. This system is suitable for producing cookies with various designs and complex shapes.

- Baking and Cooling: The formed biscuits are fed into a tunnel oven via a mesh belt. The baked cookies are then cooled in a cooling line.

- Decorating and Packaging: The cooled cookies can be decorated as desired, such as with powdered sugar or chocolate coating. Finally, they are weighed, bagged, and sealed for packaging.

Parameters of Cookie Production Line

| Equipment | Specifications | Voltage | Power | Dimensions (mm) | Weight |

|---|---|---|---|---|---|

| Dough Mixer | Best mixing capacity: 10 bags/flour per batch | 380V | 28kW (mixing), 0.75kW (tipping) | 2400×1550×1996 | 2200kg |

| Dough Slicer | Slice width: 600mm, Thickness: 10-100mm (adjustable), Hydraulic pressure: 6.3MPa | 24V/220V/380V | 4.1kW | 2600×1060×1200 | 620kg |

| Dough Lift Conveyor | Lift height: 2000mm, Conveyor width: 1000mm | 220V/380V | 1.5kW | 5200×1060×2000 | – |

| Three-Roll Dough Sheeter | Sheeting width: 800mm, Thickness: 10-20mm, 3 refrigerated rollers | – | – | 1600×1810×1250 | 1280kg |

| Two-Roll Dough Sheeter | Sheeting width: 1000mm, Thickness: 2-10mm, 2 refrigerated rollers | – | 6.36kW (total) | 1600×1610×1250 (×2 units) | 1280kg |

| Tough Biscuit Forming Machine | Sheeting width: 1000mm, Thickness: 0.7-20mm | – | 1.85kW | 2200×1810×1250 | 1100kg |

| Dough Separation Machine | PU belt width: 1000mm, Return belt width: 1000mm | 380V | 2.2kW | 1950×1810×1450 | – |

| Two-Stage Feeder | Conveyor PU width: 1000mm | – | 1.1kW (×2 units) | Upper: 9600×1050×1900, Lower: 8200×1050×1700 | – |

| Biscuit Spraying Machine | Conveyor width: 1020mm, Air pressure: 0.1-0.25Pa | 380V/24V | 0.55kW | 1200×1300×600 | – |

| Biscuit Transition Machine | Conveyor width: 820mm, Arm length: 1500mm | – | 1.1kW | 2140×1610×1020 | – |

| Pre-Oven Conveyor | Air pressure: 8-10kgf/m² | – | – | 1800×1930×1100 | 850kg |

| Electric Tunnel Oven (40m) | Production: 1350kg/h (crisp), 900kg/h (tough), Heating zones: 3, Width: 1200mm | – | 20kW (burners), 3.75kW (fans), 1.1kW (slag removal) | 40000×2040×1400 | 22000kg |

| Oven Control Cabinet | – | – | – | 1000×300×1700 | 120kg |

| Post-Oven Conveyor | – | 380V | 3kW | 1800×1930×1100 | 800kg |

| Crumb Separator | – | 380V | 0.75kW | 1200×1280×900 | 180kg |

| 90° Turning Machine | Heating power: 2kW | 380V | – | 2100×2100×850 | 250kg |

| Biscuit Oil Sprayer | Heating power: 16kW | 380V | – | 2000×1280×1400 | 580kg |

| Oil Drain Cooling Line | – | 380V | 1.1kW | 6000×1220×800 | 280kg |

| Lift Conveyor (10m) + 3-Tier Cooling Line (10m×3) | – | 380V | 6kW | 10000×820×1800 (lift), 10000×820×1800×3 (cooling) | 3500kg |

| Biscuit Arranger | – | 380V | 3.75kW | 3500×1300×1000 | 450kg |

| Biscuit Sorting Table | – | 380V | 2kW | 10000×1220×780 | 350kg |

| Biscuit Molds | Roller length: 1000mm, Diameter: 250mm | – | – | – | 30kg |

| Vibrating Biscuit Dropper | – | 220V | 0.25kW | 2000×350×1000 | – |

| High-Speed Pillow Packager | Speed: 100-300 packs/min, Film width: <360mm | 220V | 4.8kW | 3900×800×1550 | 500kg |

| 10kW Air Compressor | – | – | 10kW | – | – |

Free Quote! WhatsApp/Tel: +86 13838385752.

Features of Biscuit Processing Line

Equipment Design

The entire line utilizes a modular structure, allowing customers to select the right machine based on their current budget and product plan.

Forming Technology

A variety of forming methods and cookie shapes are available to meet customer needs.

Hot Air Circulation System

The oven utilizes advanced hot air circulation technology and a temperature control system to ensure uniform temperature within the oven.

Intelligent Control System

The production line is controlled by a PLC and features a touch screen, enabling real-time monitoring of production data and storage of multiple product recipes.

Advantages of Automatic Biscuit Production Line

Selectivity

Our biscuit production lines are divided into crisp biscuit lines and hard biscuit lines. And customers can choose according to their needs.

Automation

Automated production reduces reliance on manual labor, minimizing the risks associated with staff turnover and reducing training costs.

Quality

The equipment ensures highly consistent biscuit weight, shape, color, and taste.

Raw Material Utilization

A standardized dosing system minimizes raw material waste and lowers production costs.

Why Choose Foodline Machinery

- Customized service

- After-sales service support

- Professional R&D team

Welcome to contact us and choose a professional cookie production line. WhatsApp/Phone: +86 13838385752.