In today’s fast-paced food industry, investing in a cookie production line is a great choice. Whether you are building a new plant or upgrading existing equipment, our integrated Crisp biscuit equipment solutions can help you produce high-quality cookies. From dough mixing to final cooling, every stage has been carefully designed. If you want to know more about our products, please contact us. WhatsApp/Phone: +86 13838385752.

Biscuit Production Line Equipment Parameter

| Product | Voltage | Optimal Mixing Capacity | Motor Power | Dimensions (mm) | Weight | Other Specifications |

|---|---|---|---|---|---|---|

| Dough Mixer | 380V / 24V | 75kg/batch | 6.75 kW | 1600×1400×1800 | – | – |

| Shortbread Forming Machine | 380V / 24V | 80-200 kg/h (adjustable) | 3.57 kW | 3500×980×1560 | 1200 kg | – Roller printing width: 400mm – Roller pairs: 1 – Conveyor speed: 10~35 mm/s – Continuous operation |

| Hot Air Circulation Rotary Oven | 380V / 24V | 100 kg/h | 3.5 kW | 2200×1960×2450 | 1300 kg | Air consumption: 6-7 m³/h |

| Stainless Steel Baking Cart | – | – | – | 640×840×1740 | 35 kg | – |

| Cooling Conveyor (12m) | 380V | – | 2 kW | 14000×620×800 | 430 kg | – |

| Roller Printing Biscuit Mold | – | – | – | Length: 400mm Diameter: 205mm | 30 kg | – |

| 400×600 Peach Crisp Baking Tray | – | – | – | 400×600 mm | 2.5 kg | – |

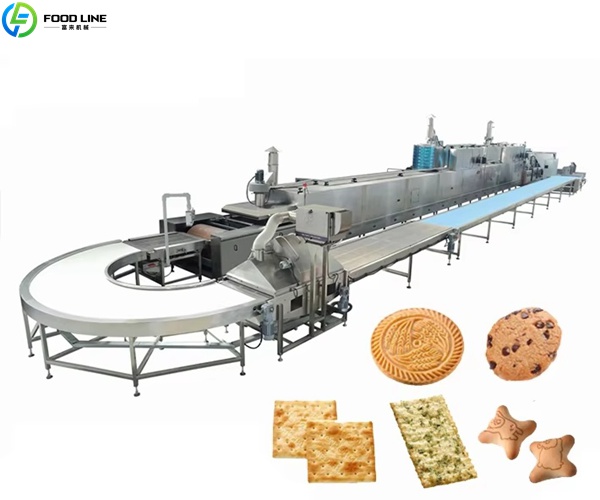

Complete Cookie Production Line

- Dough Mixer: The equipment is equipped with a stainless steel mixing barrel with forward and reverse mixing functions. The inner lining is made of food-grade 304 stainless steel, which is hygienic and durable.

- Shortbread Forming Machine: Semi-automatic roller printing machine. It uses iron rollers and blade scrapers to shape the cookies and then transfer them to the baking tray.

- Hot Air Circulation Rotary Oven: Equipped with Italian imported burners, double-layer insulation doors, and internal lighting. Electric heating, diesel heating, or gas heating modes can be provided according to local conditions.

- Stainless Steel Baking Cart: Made of food-grade materials, it can accommodate 16 layers of trays. Each layer can accommodate 2 trays for efficient batch baking.

- Cooling Conveyor: Adopts PU conveyor belt with automatic tension adjustment and speed control for cooling cookies after baking.

- Roller Printing Biscuit Mold: Customizable, removable, easy to clean, designed for precise shaping.

- Peach Crisp Baking Tray: Durable double-sided coated baking tray for even heating and easy cleaning.

Crisp Biscuit Equipment Features

Each component of our cookie production line is built with detail and durability in mind. Key features include:

- Food-grade materials: All surfaces in contact with food are made of stainless steel to ensure safety and hygiene.

- Custom mold design: The roller molds used to mold cookies are interchangeable and can be customized with different patterns or sizes.

- Energy-saving baking: Our hot air ovens heat evenly and are insulated by fiberglass insulation.

- Automated process control: Adjustable speed motors, automatic tension correction, and stable conveyor operation reduce manual intervention.

- Multi-fuel heating options: Depending on your local energy supply, you can choose electricity, diesel, or natural gas heating.

Production Process of Crisp Biscuit Machines

The cookie production line follows a simple and efficient step-by-step workflow:

- Dough mixing: The raw materials are mixed in an automatic dough mixer, which mixes in both directions to ensure a uniform and consistent dough.

- Dough forming and shaping: The mixed dough is fed into a forming machine, where it is rolled, stamped, and cut using custom molds.

- Baking: The formed dough is transferred to trays. It is then loaded into a stainless steel cart and sent to a rotary hot air oven for uniform baking.

- Cooling: The baked cookies are sent to the cooling conveyor line, where conveyor belts and fans reduce the temperature for packaging.

Each stage is automated to reduce human errors and ensure hygiene throughout the process.

Advantages of Cookie Machines

This cookie line offers outstanding performance and reliability. Its unique features include:

- High output and consistency: Precise shaping and uniform baking ensure consistent appearance and taste of cookies.

- Flexible customization: The system supports a wide range of cookie shapes, with a variety of shapes for you to choose from.

- Easy to clean and maintain: Removable molds, stainless steel frames and Teflon trays ensure quick cleaning.

- Compact footprint: The space-saving layout makes this line a great fit even for medium-sized factories.

- One-stop solution: From raw materials to cooling the finished product, no additional equipment is required.

Investing in this line means less waste, faster production and greater profits.

Customer Success Story

Mr. Dimas Setiawan, a biscuit manufacturer from Indonesia, shared his experience: “We have been using the Foodline biscuit line for over a year. It has really expanded our business. The forming machine makes perfect shapes every time and the rotary oven bakes evenly. We can produce a large amount of biscuits per day with only a few operators. It is efficient, clean and easy to manage. Highly recommended!”

Why Choose Us: Foodline Machinery Advantages

With Foodline Machinery, you are buying more than just a production line. You are buying a long-term partner committed to your success.

- 20 years of experience in food machinery manufacturing.

- Strong customer support with exports to over 30 countries worldwide.

- Solutions tailored to your recipe, space and capacity needs.

- High-quality materials and components.

- After-sales technical support and fast spare parts delivery.

Whether you want to expand your production scale or launch a new biscuit brand, our biscuit production line can meet your needs. With high-quality biscuit equipment, efficient process flow, and full support from the Foodline Machinery team, you will be able to have your ideal production line. Don’t hesitate, contact us now to get a quote and start your dream production line! WhatsApp/Phone: +86 13838385752.

In addition to biscuit production lines, we also have French fries and potato chips production lines and peanut butter production lines.