Efficiency, quality, and hygiene are key priorities in the food industry. Our tortilla production line for sale is designed to help food factories, restaurants, and caterers achieve high-capacity, automated tortilla production. Whether producing tortillas, tacos, or Peking duck tortillas, this tortilla production line delivers the speed you need. It delivers consistent quality and reliable performance, helping you grow your business and meet customer demands.

Our tortilla production lines are available in two models: the FL-650 and FL-720, both offering high efficiency and flexibility for production of varying sizes. If you’re interested in our products, please contact us for inquiries! WhatsApp/Phone: +86 13838385752.

Parameters of Tortilla Lines

| Technical Parameters | FL-650 | FL-720 |

|---|---|---|

| Production Capacity | 6-inch: 6000-8000 pes/h | 6-inch: 6000-8000 pes/h |

| 8-inch: 3000-4000 pes/h | 8-inch: 3000-4000 pes/h | |

| 10-inch: 3000-4000 pes/h | 10-inch: 3000-4000 pes/h | |

| 12-inch: 3000-4000 pes/h | ||

| Overall Dimensions (mm) | 17000×1800×1850 | 21000×1555×2080 |

| Power (output) | 60 kW | 70 kW |

| Weight | 5500 kg | 5500 kg |

| Product Diameter | 6-10 inches | 6-10 inches |

Features of Tortilla Production Lines

Fully Automated Continuous Production

The tortilla production line automates the entire process, from dough separation, proofing, forming, baking, cooling, and stacking. This not only reduces manual labor but also improves production efficiency.

Flexible Switching for Multiple Sizes

This machine can produce tortillas in various sizes, including 6-inch, 8-inch, 10-inch, and 12-inch, to meet the needs of diverse markets, including supermarkets, restaurants, and takeout.

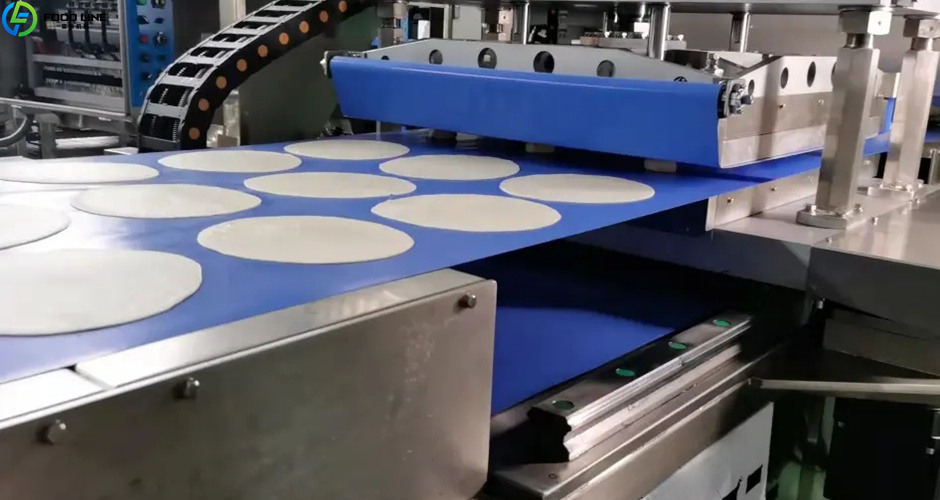

High-Precision Forming System

Advanced pressing and forming technology ensures consistent diameter, thickness, and shape for each tortilla, resulting in a neat and beautiful finished product.

Food-Grade Stainless Steel Construction

The production line is constructed of food-grade stainless steel, which is corrosion-resistant, easy to clean, and complies with international food hygiene and safety standards.

Energy-Saving and Environmentally Friendly Design

The heating system is highly energy-efficient, reducing energy waste and lowering operating costs, supporting sustainable production.

Smart Control Panel

The one-touch interface features real-time monitoring and fault alarms, allowing operators to easily master the system without extensive training.

Advantages of Tortilla Machines

Significant Labor Cost Savings

Fully automated production can replace multiple skilled workers, making it particularly suitable for regions with high labor costs and providing a rapid return on investment.

Guaranteed Product Stability

Automation and precision control ensure highly consistent weight, thickness, and taste from batch to batch, enhancing brand image.

High Production Capacity

Capable of producing up to 8,000 tortillas per hour, the factory can easily meet peak season orders and meet the needs of large customers.

Versatile Production

Fully automated production replaces multiple skilled workers. It is ideal for regions with high labor costs. The system ensures a rapid return on investment.

Reduced Material Waste

Precision cutting and forming technologies reduce scrap and scrap, lowering production costs.

Stable and Durable

High-strength components and an industrial-grade drive system ensure long-term, stable operation under high loads, minimizing downtime for maintenance.

Easy to Clean and Maintain

The surface is smooth and has no dead corners, which allows for quick cleaning after production, reducing the risk of cross-contamination and extending the service life of the machine.

Burrito Production Line Operation Process

- Dough Preparation – A dough divider is used to divide large dough pieces into smaller pieces.

- Dough Shaping – A divider is used to shape the smaller pieces of dough into balls to maintain uniform size.

- Proofing – The dough balls enter the proofer to rise for 10-15 minutes to reach their optimal state.

- Forming – The fermented dough is conveyed via a conveyor to the main forming machine, where it is formed into flat tortilla discs.

- Baking – The formed dough enters the oven and is baked to perfection at a controlled temperature.

- Cooling – The baked tortillas are cooled on cooling racks to prevent sticking and maintain their texture.

- Stacking and Packaging – The cooled tortillas are stacked and organized for packaging and distribution.

FAQ

Our tortilla production line can produce tortillas ranging from 6 inches to 12 inches in diameter. Size adjustments are easily made through the machine’s control settings, eliminating the need for complex die changes.

Depending on the model and tortilla size, this tortilla production line can produce up to 8,000 per hour, making it ideal for medium and large-scale production runs.

Absolutely. We offer remote installation guidance and training services worldwide to ensure a smooth and efficient start-up of your production.

Why Choose Foodline Machinery

- Decades of manufacturing experience: Our expertise in food machinery ensures reliable, high-performance equipment.

- Customized solutions: We offer custom options to meet your specific production capacity, product size, and facility layout.

- Global service network: From customization to after-sales support, our technical team provides expert guidance worldwide.

- Quality assurance: Each tortilla production line undergoes rigorous quality inspections before delivery.

- Training and maintenance support: Provides comprehensive operator training and regular maintenance recommendations to extend the life of your equipment.

Don’t let manual production hold you back. Upgrade to our advanced tortilla production solutions today and boost your business. Contact us today for a customized quote and start your journey to greater productivity and profitability. WhatsApp/Phone: +86 13838385752.