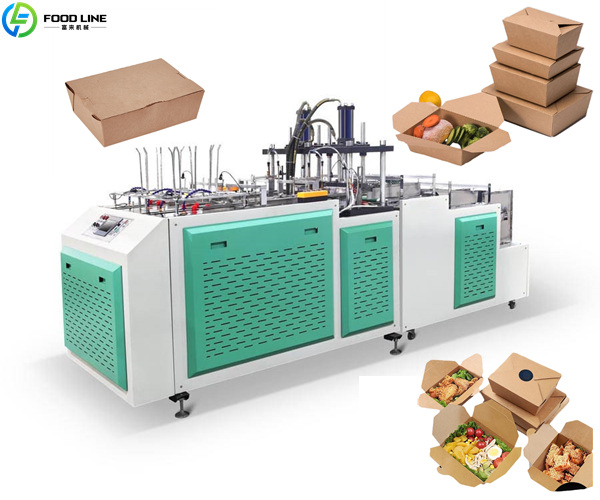

The paper box forming machine is a fully automatic paper product forming machine that integrates pneumatic and mechanical motions. It is designed specifically for the production of various paper lunch boxes. It is suitable for manufacturing disposable paper lunch boxes with lids, paper lunch boxes, kraft paper food packaging boxes, and multi-compartment lunch boxes. The machine integrates automated feeding, hot pressing, and intelligent control technologies.

If you want to get more product information, please feel free to consult! WhatsApp/Phone: +86 13838385752.

Specifications of Food Container Making Machine

| Specification | Details |

|---|---|

| Model | FL-400B |

| Production Capacity | 35~45 pcs/min |

| Maximum Paper Size | 480x480mm |

| Suitable Material | 200~400g/m² PE coated paper, etc. |

| Total Power | 5kw |

| Voltage Requirement | 380V 50HZ |

| Total Weight | 350kg |

Paper Box Forming Machine Features

Pneumatic-Mechanical Synergy

The paper box forming machine utilizes a design that combines pneumatic and mechanical motion. This design offers the advantages of high speed, ease of operation, high efficiency, and environmental friendliness. The pneumatic system provides power for the forming process, while the mechanical structure ensures the quality of the lunch box forming, making the lunch box production process efficient and stable.

Intelligent Control and Fault Monitoring

The paper box forming machine is equipped with a touchscreen intelligent control system. Operators can intuitively set various production parameters, enabling control of processes such as feeding, hot pressing, and counting. A built-in fault monitoring function provides real-time monitoring of the machine’s operating status. Immediate warnings are issued for program anomalies, component failures, and other issues, facilitating rapid troubleshooting and resolution.

Material Compatibility

The machine supports a variety of materials, including PE-coated paper and kraft paper, weighing 200-400g/㎡. It can produce lunch boxes with lids, multi-compartment lunch boxes, and kraft paper food boxes. This compatibility allows companies to easily meet the diverse packaging needs of the catering and food retail sectors.

Design

The modular design allows for independent yet tightly connected functional units. During routine maintenance, specific modules can be inspected or replaced without disassembling the entire device.

Free Quote! WhatsApp/Tel: +86 13838385752.

Advantages of Lunch Box Forming Machine

Product Quality

Through pneumatic-mechanical coordinated control and intelligent program execution, the produced lunch boxes feature secure bonding, uniform shapes, and minimal dimensional error. This consistent quality enhances brand recognition in the market, reduces returns and complaints caused by packaging defects, and fosters a reliable market image for the company.

Production Efficiency

The paper box forming machine boasts a production speed of 35-45 pieces/minute, offering significant efficiency. It can meet large-scale orders from restaurant chains and food processing companies, helping them shorten delivery cycles.

Low Operating Costs

The fully automated production mode requires only one person to operate the equipment, significantly reducing labor input. The equipment boasts high material utilization and precise mechanical movements, minimizing raw material waste.

Environmentally Friendly

The PE-coated paper and kraft paper used in production meet environmentally friendly food packaging requirements. Furthermore, the equipment boasts high energy efficiency, resulting in a low-carbon and energy-efficient production process.

FAQ

Yes. By replacing the corresponding mold, the equipment can quickly switch to produce lunch boxes of different sizes and varieties. The mold replacement process is simple.

The equipment requires a 380V 50Hz power supply. The company must ensure that the workshop power system can stably provide this power to ensure normal operation of the equipment.

Regularly clean and inspect the mechanical transmission parts of the equipment. Keep the surrounding environment of the equipment clean and tidy to avoid dust and debris that may affect the performance of the equipment.

Customer Success Stories

A US fast food brand needed to increase its lunch box supply capacity due to business expansion. After installing a paper box forming machine, its lunch box production efficiency improved. The quality of the lunch boxes produced by the machine was also stable, resulting in a corresponding increase in customer praise. Furthermore, the fully automated production model reduced labor costs for the company.

About Foodline Equipment

- After-sales service

- CE certification

- Export experience

- Professional design team

We also have food sterilizers. Feel free to contact us! WhatsApp/Phone: +86 13838385752.