The tomato sauce, ketchup, tomato puree, and other condiments hold an important place in the food market. Our tomato sauce production line aims to improve production capacity and product quality. Contact us for a quote! WhatsApp/Phone: +86 13838385752.

Overview of Tomato Sauce Production Line

A ketchup sauce production line integrates raw material pretreatment, juicing, concentration, sterilization, filling, and packaging into a fully automated system. This production line mainly processes fresh tomatoes to produce various tomato sauce products, and the entire production line uses food-grade stainless steel. It meets hygiene standards, operates stably, and has low energy consumption. It can be customized to meet the production needs of different factories.

Parameters of Ketchup Production Line

| Equipment Name | Material | Dimensions | Power | Belt Width | Voltage | Other Parameters |

|---|---|---|---|---|---|---|

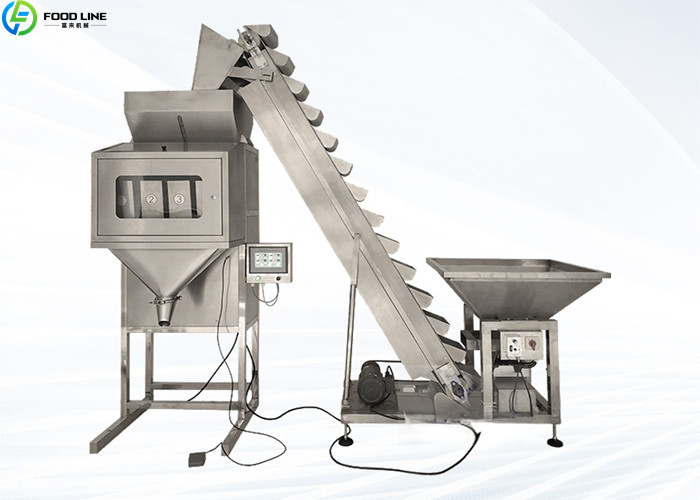

| Elevator | 304 / 201 | 2200×1100×1800 | 0.55 kW | 800 mm | 380V 50Hz | / |

| Bubble Washing Machine | 304 / 201 | 6000×1500×1290 | 7.2 kW | 800 mm | 380V 50Hz | / |

| Blanching Machine | 304 / 201 | 6000×1200×1300 | Transmission: 1.5 kW Circulation Pump: 3 kW Heating Power: 180 kW | 800 mm | 380V 50Hz | Humidity: 60-98°C adjustable Heating Method: Electric/Steam Speed: Frequency conversion adjustable |

| Cooling Line | 304 / 201 | 6000×1500×1290 | 5.7 kW | 800 mm | 380V 50Hz | / |

| Sorting Platform | 304 | 6000×800×800 | 1.1 kW | / | 380V 50Hz | Conveyor Belt: Food-grade PU |

| Tomato Pulper | / | / | 5.5 kW | / | 380V 50Hz | Processing Capacity: 1-1.5 T/H |

Workflow of Tomato Sauce Production Line

- Bubble Washing: Tomato raw materials are washed using a tumbling bubble method to remove mud and impurities without damaging the skin.

- Blanching: Rapid blanching loosens the tomato skin, facilitating subsequent peeling and maintaining the integrity of the flesh.

- Cooling: After blanching, the tomatoes are rapidly cooled via a cooling line to prevent over-softening and ensure stable taste and structure.

- Sorting, Stem Removal, and Peeling: Workers manually or semi-automatically sort the tomatoes using a sorting platform and remove the stems and skins.

- Juicing: The tomato pulping machine crushes and pulps the processed tomatoes, and it separates the pulp from the skin and seeds to obtain a fine tomato pulp.

- Sauce Making: The tomatoes are heated and concentrated using evaporation and concentration equipment to achieve the desired consistency.

- Bottling: This production line fills the prepared tomato sauce into cans, bottles, bags, and other packaging formats to meet different market demands.

- Sterilization: High-temperature sterilization equipment sterilizes the finished product to extend its shelf life and ensure food safety.

- Packaging: After sterilization, the product undergoes external cleaning, air drying, and outer packaging to complete the final product process.

Features of Tomato Sauce Processing Line

- Automation: From cleaning to packaging, the production line automates most processes and significantly reduces the need for manual intervention.

- Stability: All equipment uses food-grade 304/201 stainless steel, delivering high stability and supporting long-term continuous production.

- High Hygiene Standards: Utilizing an open structure and detachable design, it meets CE certification and food safety requirements.

- Multiple Product Compatibility: Capable of producing various food products such as tomato sauce and chili sauce, offering versatility.

- Output: From small to large production lines, we can provide customized solutions.

Advantages of Tomato Ketchup Production Line

- Quality: Standardized processes ensure consistent flavor and uniform color.

- Operating Costs: High energy efficiency and intelligent design reduce overall equipment operating costs.

- High Raw Material Utilization: A scientifically designed juicing and pulping system maximizes the use of tomato raw materials, increasing pulp yield.

- Scalability: The production line is upgradeable, allowing for the addition of modules such as filtration, secondary concentration, and fully automated filling.

- Comprehensive Technical Support: We provide installation training, process training, and after-sales technical support to ensure smooth production for our clients.

FAQ

Suitable for tomatoes and chili peppers.

Yes, it can produce tomato sauces of varying concentrations according to customer needs.

Fully customizable, including output, equipment size, and level of automation.

Why Choose Foodline Equipment?

- Equipment Manufacturing Experience: We have 20 years of experience in mechanical equipment manufacturing.

- Technical Support: We provide installation, commissioning, training, and after-sales service.

- Quality: Our equipment meets international standards such as CE and ISO.

In addition to this production line, we also offer tomato jacketed kettles. Please feel free to contact us for more information about our tomato production lines! WhatsApp/Phone: +86 13838385752.