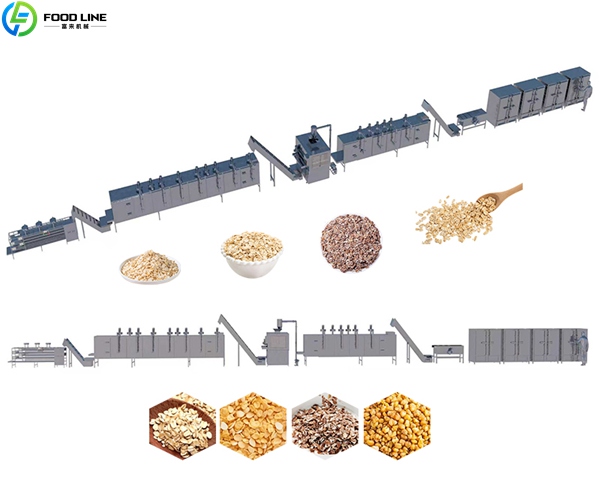

A professional corn flakes production line can automate the entire process from raw material processing, extrusion puffing, tableting, drying, baking to cooling and packaging. It produces multiple product types, including corn flakes, breakfast cereals, and puffed cereals. Food processing companies, cereal brand factories, and large chain manufacturers widely adopt this system because it supports stable, large-scale production.

The entire production line is based on twin-screw extrusion technology. The system includes a high-speed tablet press, a multi-layer belt dryer, a high-temperature puffing and baking unit, and a pneumatic conveying system. Our equipment has advantages in energy consumption, product quality, and production efficiency, making it a reliable cereal solution in the industry. Feel free to get a quote! WhatsApp/Phone: +86 13838385752.

Parameters of Cereal Production Line

| Equipment | Max Capacity / Output | Power | Weight | Dimensions (L×W×H) / Other Specs |

|---|---|---|---|---|

| Mixing Tank | 900 L | 4 kW | 180 kg | φ1150*2070 mm |

| Feed Pump | 5 m³ | 3 kW | – | Caliber: 40 mm |

| Impact Grinder | – | 11 kW | 230 kg | 990*440*1050 mm |

| Storage Tank | 900 L | 3 kW | 170 kg | φ1150*2070 mm |

| Feed Pump | 5 m³ | 3 kW | – | Caliber: 40 mm |

| Flake Drum Dryer | 10-12 ton/24h | 22 kW | 25 ton | 5200*3600*4800 mm Roller: φ2000*4000 mm Steam Pressure: 0.6-1.0 MPa Steam Consumption: 300 kg/h |

| Primary Crusher | – | 3 kW | 480 kg | 5750*540*1470 mm |

| Inclined Conveyor | – | 3 kW | 230 kg | 4020*406*500 mm |

| Flake Pelletizer | 450 kg/h | 3 kW | 120 kg | 1320*786*2010 mm |

| Cyclone Grinding Unit | 350-400 kg/h | 11 kW | – | 3500x820x2500 mm Spindle Speed: 4000 r/min Fineness: 60-80 mesh Material: 304 Stainless Steel Power Supply: 3-phase 380V 50-60Hz |

Workflow of Cereal Processing Line

- Raw Material Proportioning: Corn flour, syrup, and other ingredients are fed into a mixer and proportioned to form a premixed material.

- Twin-Screw Extrusion Expansion: The mixed material enters a twin-screw extruder. This equipment uses high-temperature, high-pressure, instantaneous extrusion technology to make the grain structure more brittle, facilitating subsequent tableting.

- Tableting: The extruded grains enter a high-speed tablet press, where high-hardness rollers press them into thin sheets.

- Drying: The tableted product enters a multi-layer belt dryer, where hot air penetrates and dehydrates it.

- Roasting: The product is conveyed to a high-temperature air environment, where airflow completes secondary extrusion or roasting.

- Cooling: The pneumatic conveying system moves the product into the cooling unit to reduce its temperature rapidly.

- Packaging: Finished oatmeal is output through automatic weighing, metering, and packaging equipment.

Features of Cereal Forming Machines

- Energy Saving: The production line features a low moisture content design for the materials, reducing energy consumption during the drying stage. Compared to traditional equipment, energy consumption can be reduced by 25-40%. The high-temperature baking system utilizes circulating air heating, improving thermal energy utilization.

- Environmentally Friendly: No wastewater, exhaust gas, or waste is generated during the processing stage. The entire workflow avoids environmental pollution. A closed-loop conveyor system safely transports materials between machines, preventing raw material loss. This improves production efficiency and reduces overall operating costs.

- Small Footprint: Advanced technology and compact layout require less manpower and occupy a small area. The production process is continuous and stable, with minimal fluctuations in finished product quality.

- Adaptability: The production line can produce various grain foods by adjusting the formula and molds. It also supports product manufacturing across different sub-sectors and meets diverse market demands with strong adaptability.

- Innovative Technology Support: Utilizing a high-temperature roller structure ensures uniform expansion and eliminates scorching. The tablet press features innovative technology. The pressure rollers use a special high-hardness material with a hardness level exceeding 65 degrees. The internal water-cooling circulation structure stabilizes the temperature, ensures uniform tablet pressing, and reduces noise and vibration.

Advantages of Corn Flakes Production Line

- Design: Utilizing 3D software design and simulation, the entire production line boasts high design precision and minimal processing errors. The modular system facilitates expansion and upgrades, meeting the personalized production needs of diverse users.

- Technology: Experienced twin-screw extrusion technology has been successfully applied in breakfast cereals, pet food, aquatic feed, and other fields. The equipment operates smoothly, with low noise, minimal wear, and a long service life.

- Materials: All food-contact parts are made of 304 stainless steel. Exposed parts are all electroplated, providing enhanced corrosion resistance and ensuring food hygiene and safety.

- Drying: The multi-layer belt dryer features a simple structure and is easy to maintain. Hot air penetrates from bottom to top, achieving high-efficiency drying. It is highly adaptable, meeting the drying requirements of various food materials and ensuring good product consistency.

- High-Temperature Process: The high-temperature air circulation system enables non-frying production. This technology is healthier while reducing production costs and oil consumption.

- Conveying: High conveying capacity and small footprint. It stably enables rapid material transfer from extrusion, drying, to baking stages, improving overall line efficiency.

Why Choose Foodline Equipment?

- CE Certification

- After-sales Service

- Equipment Quality

- Export Experience

In addition, we also have bread production lines. If you are interested in a cereal production line, please feel free to contact us for a quote! WhatsApp/Phone: +86 13838385752.