Baking equipment is an essential component of baking factories and food processing enterprises. Industrial tunnel ovens offer advantages such as continuous production and stable capacity. They are used in the production of various baked and cooked foods. Request a quote! WhatsApp/Phone: +86 13838385752.

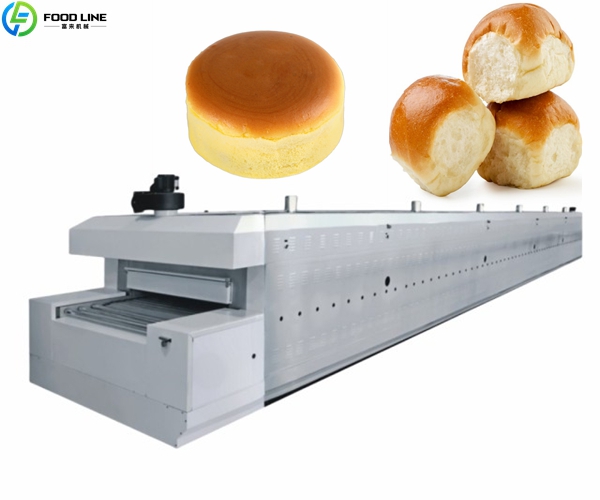

Commercial Tunnel Oven

An industrial tunnel oven is an oven that uses a continuous conveyor system for baking. Driven by a high-temperature resistant conveyor belt or chain plate, the product passes through a heating zone and completes the baking process under set time and temperature conditions. Compared to traditional ovens, tunnel ovens enable continuous operation and are more suitable for mass production needs.

A tunnel oven typically consists of an oven body structure, heating system, conveying system, temperature control system, and electrical control system. The equipment can use electric or gas heating.

Specifications of Industrial Tunnel Oven

| Technical Parameter | FL-14D | FL-14Q | FL-20D | FL-20Q |

|---|---|---|---|---|

| Specification | 2 Tray | 2 Tray | 3 Tray | 3 Tray |

| Heating Type | Electric | Gas | Electric | Gas |

| Voltage | 380V | 380V | 380V | 380V |

| Power | 10 kW/m | 0.2 kW/m | 15 kW/m | 0.4 kW/m |

| Energy Consumption | 4 kW/m/hour | 0.5 m³/m/hour | 6 kW/m/hour | 0.75 m³/m/hour |

| Cavity Width | 1400 mm | 1400 mm | 2000 mm | 2000 mm |

| Dimension (L × W × H) | Customizable × 2300 mm × 1680 mm | Customizable × 2300 mm × 1780 mm | Customizable × 2900 mm × 1680 mm | Customizable × 2900 mm × 1780 mm |

| Net Weight (MW) | 680 kg/m | 750 kg/m | 900 kg/m | 980 kg/m |

Automatic Tunnel Oven Applicable Products

- Cakes

- Pork floss cakes, flower cakes

- Mooncakes, hamburger buns

- Toast, French bread

- Croissant, Danish pastries

- Biscuits, cookies, and pastries

Features of Tunnel Ovens

- Structure: The tunnel oven utilizes a conveyor belt system. Raw materials enter the oven, undergo automatic baking, and exit as finished products. This reduces manual intervention and improves production efficiency.

- Temperature zone control: The oven interior is divided into multiple heating zones, each with independent temperature control. This allows for easy adjustment of heating intensity at different stages, ensuring product quality.

- Heating methods: The industrial tunnel oven supports both electric and gas heating. Users can choose based on local energy conditions and operating costs.

- Customization: The equipment dimensions can be customized to meet specific needs. The oven integrates easily with existing production lines and suits different factory layouts and production capacity plans.

- Insulation design: The oven body uses high-quality insulation materials to reduce heat loss. This improves energy utilization and enhances the workshop working environment.

Advantages of Tunnel Oven Machine

- Capacity: Tunnel ovens are suitable for large-volume order production, expanding production capacity.

- Quality: Conveyor speed and temperature control systems ensure consistent baking conditions, effectively reducing defect rates.

- Cost: High automation reduces manual operations such as turning trays and unloading. Simultaneously, reasonable energy consumption control helps reduce operating costs.

- Production Line Equipment: Industrial tunnel ovens connect seamlessly with dough mixers, dividing machines, forming machines, and cooling lines to create a complete automated baking production line.

- Maintenance: The rational structural design and durable key components make daily maintenance simple and suitable for food factories.

FAQ

Electric heating is suitable for customers with high product quality requirements. Gas heating has lower operating costs and is more suitable for large-scale continuous production.

Yes. Customization is available for various aspects, including oven dimensions, heating methods, conveyor systems, and voltage standards, according to customer requirements.

Yes. Products can be produced in the same tunnel furnace if they mature at the same temperature.

Why Choose Foodline Machinery?

We have long focused on food processing machinery, possessing mature technology and successful case studies in the field. We provide customized equipment configuration solutions based on our clients’ product type, production capacity, and factory conditions. And we offer technical consultation, solution design, installation guidance, and remote technical support to help our clients get started in production.

In addition, we also have layer ovens and convection ovens. Please request a quote! WhatsApp/Phone: +86 13838385752.