On a sausage production line, every process directly impacts the quality and appearance of the final product. Tying, in particular, determines the sausage’s aesthetic appearance, uniform length, and the ability to quickly complete large-scale production. Traditional manual tying is not only inefficient but also prone to errors, making it difficult to meet the demands of modern food processing plants. Therefore, the automatic sausage tying machine has become the choice of more and more companies. It can maintain high speed while ensuring quality, and is an efficiency-enhancing device for meat processing plants. Contact us for more information! WhatsApp/Phone: +86 13838385752.

Sausage Tying Machine Introduction

Made entirely of stainless steel, the sausage tying machine features a compact design and attractive appearance. It’s easy to operate, clean, and maintain. It’s suitable for a wide range of applications, including sheep, hog, egg white, and plastic casings, making it a truly versatile tying machine. The machine is available in two models:

- Single-channel fully automatic tying machine: Suitable for small and medium-sized production needs, it handles sausage diameters ranging from 9-28mm and single-section lengths from 10-300mm, with a production capacity of 10-200 sections/minute.

- Dual-channel fully automatic tying machine: Suitable for large-scale production, it offers the same range of applications as the single-channel model, but with significantly higher production capacity, reaching 100-600 sections/minute.

Specifications of Automatic Sausage Tying Machine

| Model | FL-I | FL-II |

|---|---|---|

| Power (kW) | 1.5 | 3 |

| Voltage (V) | 220 | 220 |

| Suitable Object Diameter (mm) | φ9~28 | φ9~28 |

| Single Crystal Length (mm) | 10~300 | 10~300 |

| Production Capacity (L/min) | 10~200 | 100~600 |

| Dimensions (mm) | 1100×550×1200 | 1100×850×1250 |

Free Quote! WhatsApp/Tel: +86 13838385752.

Features of Sausage Tying Equipment

Stainless Steel

The sausage string-tying machine is made of food-grade stainless steel, making it durable and sturdy, meeting international food hygiene standards. It features a simple, elegant appearance and is easy to clean.

Applications

It can be used with sheep, hog, protein, and plastic casings. It meets the production needs of various sausage types and is particularly suitable for the industrial production of quick-frozen Taiwanese grilled sausages and sausages.

Portioning

Sausage length can be freely adjusted between 10-300mm. This equipment ensures consistent length and uniform appearance for each sausage portion, enhancing the aesthetics and market competitiveness of the end product.

Production

Single-channel models can produce 10-200 sections per minute, while dual-channel models can reach 100-600 sections. This output far exceeds manual efficiency, helping companies easily handle large orders.

Structure

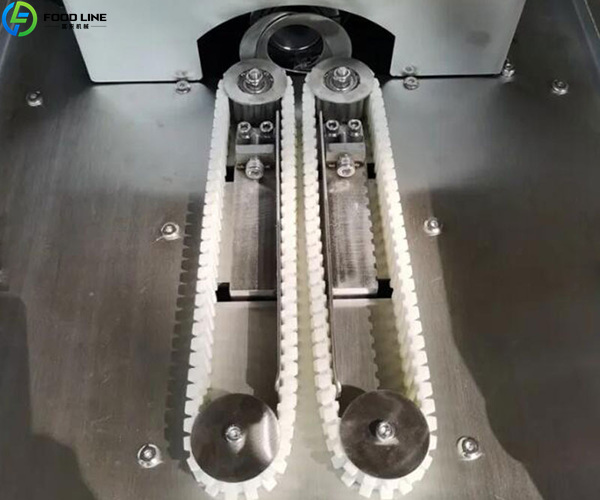

The machine occupies a small area, has a reasonable design and is easy to operate. Workers only need simple training to get started.

Advantages of Sausage Tying Knotting Machine

Labor Costs

The machine’s automated wire tying significantly reduces manual intervention, not only reducing labor costs but also avoiding the instability associated with manual operation.

Quality

The length and diameter of each sausage are virtually consistent. This creates a more aesthetically pleasing and uniform product, meeting the aesthetic and taste demands of modern consumers.

Adaptability

Both single- and dual-channel machines cover most sausage production needs, with diameters ranging from 9 to 28 mm and lengths from 10 to 300 mm, offering high compatibility.

Large-scale

Single-channel machines are suitable for small and medium-sized enterprises, while dual-channel machines are suitable for large factories and export-oriented manufacturers, helping customers find the optimal production solution.

Working Principle of Sausage Tying Machine

The core principle of the automatic sausage tying machine lies in automated portioning and precise string tying:

- After filling, sausages enter the string tying machine.

- The machine automatically identifies and portions sausages according to the set length (10-300mm).

- The string tying system operates at high speed, sealing the sausages and forming standardized, individual sausage sections.

This automation principle ensures the consistency and efficiency of production, making the products not only neat and beautiful, but also maintaining a stable taste and quality.

FAQ

Yes. The equipment can be seamlessly connected with different types of sausage stuffers to achieve continuous production and further improve efficiency.

The equipment is very easy to maintain. You only need to clean the body and check the transmission parts regularly. The manufacturer also provides a detailed maintenance guide.

Yes, the device supports free setting between 10-300mm to meet the needs of different products.

Why Choose Our Company

Foodline Machinery is a large machinery company with 20 years of experience, focusing on the field of food machinery. In the field of sausage processing equipment, we always adhere to customer needs as the core, relying on years of experience and continuous innovation to provide high-performance automatic sausage tying machines to customers around the world.

- Advanced Technology

- Quality Assurance

- Diverse Options

- Comprehensive Service

In sausage production, the efficiency and precision of the string-tying process directly determine product quality and production capacity. Automatic sausage-tying machines solve the problems of low efficiency and instability caused by manual labor. If you’re looking for a sausage tying machine with superior performance and adaptability, our equipment is undoubtedly the ideal choice. In addition, we also have sausage production lines. Contact us now! WhatsApp/Phone: +86 13838385752.