For agricultural products like vegetables and fruits, washing is a critical step in ensuring product hygiene and safety. Cleaning methods not only affect appearance and quality but also directly impact consumer health. Bubble washers utilize high-pressure bubble cleaning technology, ensuring cleanliness while improving water efficiency.

Bubble Cleaning Machine Overview

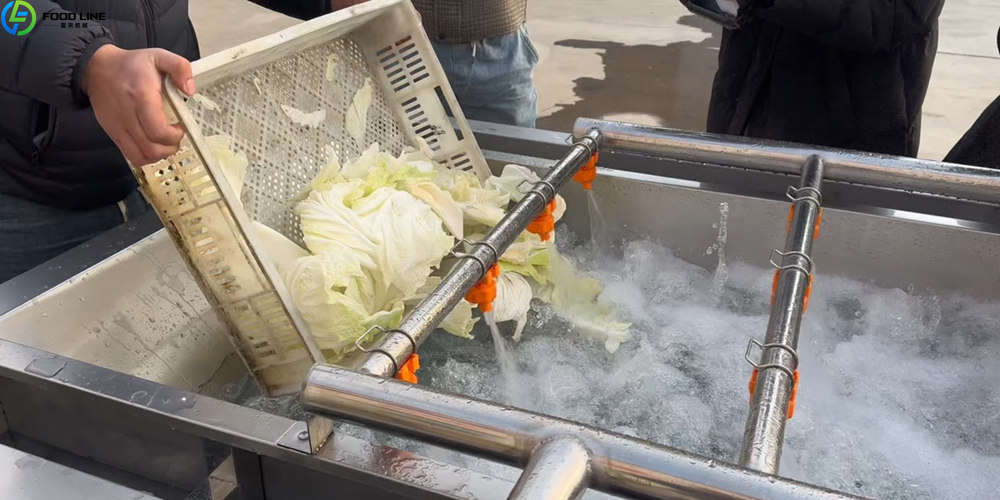

The bubbling cleaning machine is ideal for agricultural products with soft, easily damaged surfaces. Using a high-pressure bubble generation system, this equipment creates bubbles within the cleaning tank, effectively removing sediment, impurities, and dirt adhering to the surface of the product. This cleaning machine is widely used in food processing companies, central kitchens, fresh produce distribution centers, and large-scale catering operations.

Capable of processing 600–1000 kg of material per hour, this medium-sized cleaning machine meets the needs of continuous production without taking up excessive space.

Parameters of Vegetable Cleaning Machine

| Model | FL-G350 |

|---|---|

| Size | 3500 × 1100 × 1620 mm |

| Voltage | 380 V |

| Power | 4.9 KW |

| Total Output | 600-1000 kg/h |

Features of Fruit and Vegetable Cleaning Machine

High-Pressure Bubble Cleaning Technology

A bubble generator injects air into water at high pressure, creating clusters of bubbles. These bubbles create impact as they burst, causing the product to tumble and rub in the water, achieving gentle cleaning. Compared to traditional water rinsing, bubble cleaning is less likely to damage the surface of fruits and vegetables, making it particularly suitable for soft products such as leafy vegetables, strawberries, and tomatoes.

Water Circulation System

The cleaning machine is equipped with a water recirculation and filtration device, allowing water used during the cleaning process to be filtered and reused. This design not only conserves water resources but also reduces wastewater discharge, aligning with environmentally friendly production practices.

Operation

The bubble cleaning machine has a user-friendly design and a simple and intuitive control system, which allows employees to operate it with minimal training. The internal structure is easy to disassemble and clean, and the daily maintenance cost is low.

Free Quote! WhatsApp/Tel: +86 13838385752.

Advantages of Bubble Cleaning Equipment

Cleaning Effect

The combined action of air bubbles and water flow deeply removes impurities for a more thorough cleaning.

Energy Saving and Environmental Protection

Water resources are recycled, reducing waste and lowering water costs.

Product Appearance

The cleaning method avoids mechanical damage, preserving the appearance of fruits and vegetables, and minimizing waste.

Improved Production Efficiency

A processing capacity of 600–1000 kg per hour meets the needs of small and medium-sized production lines, with strong continuous operation capabilities.

Versatile Applicability

The air bubble intensity and water flow rate can be adjusted according to the type of material.

Applicable Product Range

- Leafy vegetables: spinach, lettuce, rapeseed, etc.

- Fruits: strawberries, apples, citrus fruits, grapes, etc.

- Edible fungi: enoki mushrooms, shiitake mushrooms, oyster mushrooms, etc.

FAQ

Yes. This equipment uses air bubbles and tumbling water to clean. It is suitable for materials with soft, fragile surfaces.

The equipment is equipped with a filtration system that effectively removes silt and impurities from the water. This ensures the cleanliness of the circulating water and does not affect cleaning performance.

Clean the internal filter and sedimentation tank after use. Regularly check the working condition of the bubble generator and water pump. Most accessories are removable for easy cleaning and replacement.

Why Choose Foodline Equipment

We specialize in the research, development, and manufacturing of food processing equipment, with 20 years of industry experience and accumulated technical expertise. Choosing us will provide you with:

- Product Quality: All equipment is CE certified and strictly adheres to food safety and mechanical and electrical standards.

- After-Sales Service: Our after-sales service responds within 24 hours, promptly responding to customer needs and providing spare parts and repair support.

- Customizable Solutions: We offer customized services based on your product and production requirements.

Bubble cleaners offer efficient cleaning, environmental friendliness, and easy operation, making them ideal for vegetable processing. If you’re looking for reliable cleaning equipment, a bubble cleaner is an excellent choice. Contact our professional team for more detailed product information and customized solutions. WhatsApp/Phone: +86 13838385752.

In addition, we also have blanching machines.