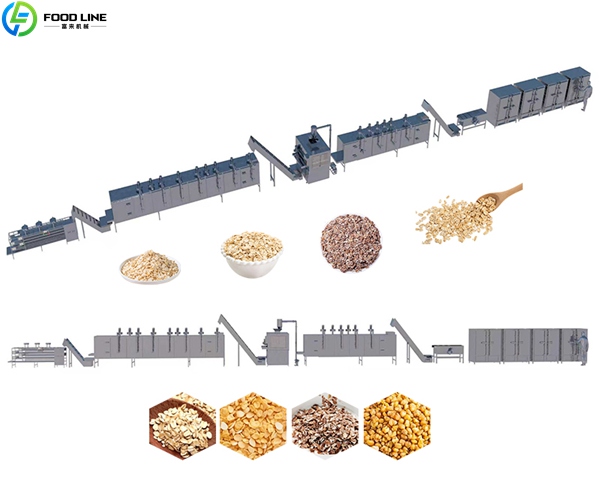

Cereal is one of the main breakfast foods. The cereal production line provides an automated production solution for manufacturing various cereal products. This line can process raw materials such as corn, oats, and rice into ready-to-eat foods such as rice flakes and cereal.

Corn Flakes Production Line Overview

The cereal production line is a fully automated system. It processes raw materials such as rice, oats, and corn into ready-to-eat products like rice flakes or cereal flakes. The entire process involves multiple stages, including slurry preparation, grinding, drying, and shaping. This ensures that the final product retains its nutritional value while meeting market demands in terms of taste. All food-contact parts of the equipment on this production line are made of food-grade 304 stainless steel or other materials that meet food production standards, guaranteeing product hygiene and safety.

The core components of this production line include a mixing tank, a colloid mill, storage tanks, a dryer, and a molding machine. The production line is also equipped with a PLC control system. This ensures a high degree of automation and precise control, effectively reducing the need for manual operation.

Specifications of Cereal Making Machines

| Equipment | Max Capacity / Output | Power | Weight | Dimensions (L×W×H) / Other Specs |

|---|---|---|---|---|

| Mixing Tank | 900 L | 4 kW | 180 kg | φ1150*2070 mm |

| Feed Pump | 5 m³ | 3 kW | – | Caliber: 40 mm |

| Impact Grinder | – | 11 kW | 230 kg | 990*440*1050 mm |

| Storage Tank | 900 L | 3 kW | 170 kg | φ1150*2070 mm |

| Feed Pump | 5 m³ | 3 kW | – | Caliber: 40 mm |

| Flake Drum Dryer | 10-12 ton/24h | 22 kW | 25 ton | 5200*3600*4800 mm Roller: φ2000*4000 mm Steam Pressure: 0.6-1.0 MPa Steam Consumption: 300 kg/h |

| Primary Crusher | – | 3 kW | 480 kg | 5750*540*1470 mm |

| Inclined Conveyor | – | 3 kW | 230 kg | 4020*406*500 mm |

| Flake Pelletizer | 450 kg/h | 3 kW | 120 kg | 1320*786*2010 mm |

| Cyclone Grinding Unit | 350-400 kg/h | 11 kW | – | 3500x820x2500 mm Spindle Speed: 4000 r/min Fineness: 60-80 mesh Material: 304 Stainless Steel Power Supply: 3-phase 380V 50-60Hz |

Working Principle of Cereal Production Line

- Pretreatment: Add raw materials to a mixing tank and mix them to form a uniform slurry.

- Grinding: The slurry is ground into a smooth paste using a colloid mill.

- Drying: The ground slurry is then sent to a cereal/rice flake drum dryer for drying.

- Shaping: The dried material enters a cereal/rice flake forming machine, which mechanically shapes it into cereal flakes.

- Granulation: The formed cereal flakes undergo granulation to achieve the required size and shape.

- Cooling and Packaging: Finally, the finished cereal flakes are cooled before being packaged.

Core Equipment for Corn Flakes Processing Line

- Mixing Tank: Used to mix raw materials and formulations, ensuring the uniformity of the slurry. This equipment can adjust its capacity according to production needs, meeting different production volumes.

- Colloid Mill: Used to grind the slurry, ensuring it reaches the ideal state; a crucial step in the entire production process.

- Cereal Drum Dryer: This equipment is the core of instant oatmeal production. Its efficient heat transfer and energy-saving design ensure effective drying of the oatmeal.

- Cereal Forming Machine: This equipment is responsible for processing the dried material into a uniform oatmeal shape.

Features of Cereal Processing Line

Automation

The production line utilizes a PLC control system, achieving a high degree of automation. You can control equipment operation and monitoring through programming, which reduces manual intervention and improves production efficiency.

Raw Materials

This production line can process a variety of raw materials. It is suitable for producing different types of oatmeal, meeting diverse market demands.

Temperature Control System

During the drying process, the oatmeal/rice flake drum dryer can control the temperature to ensure the product retains optimal nutritional components during production.

Production Capacity

The production line has a capacity of 10-12 tons/24 hours. This can be adjusted according to different production tasks.

Materials

All parts in contact with the product are made of food-grade 304 stainless steel or other materials that meet food production standards. This ensures the stability and hygiene of the equipment during long-term use.

Advantages of Corn Flakes Production Machine

Quality

The automated control system ensures precise operation at every stage of the production process, resulting in oatmeal with consistent quality, appearance, and taste.

Nutritional Components

Through temperature control and drying technology, the production line effectively preserves the nutrients in the raw materials. The final product is healthier and more nutritious, meeting the demands of modern consumers for nutritious foods.

Cost

Automated production reduces the need for manual operation and minimizes human error during production. It also lowers labor costs and increases production efficiency.

Demand

The production line can produce standard corn and oat flakes. It can also produce diverse products such as nutritious rice cereal according to customer needs, adapting to different market demands.

Efficiency

The highly efficient automated system, large-scale production capacity, and optimized production processes improve production efficiency, ensuring rapid production and timely supply of products.

FAQ

This production line can produce various cereal products, such as corn cereal, oat cereal, and rice cereal.

This production line has a production capacity of 10-12 tons/24 hours, suitable for medium to large-sized enterprises.

This production line requires a three-phase, 380V power supply.

Why Choose Foodline Equipment?

- Extensive Experience: We have many years of experience in manufacturing food production lines and can provide high-quality production equipment.

- Customization: We can provide corresponding production line designs based on our clients’ production needs.

- CE Certification: All our equipment is CE certified.

- After-Sales Service: We provide comprehensive pre-sales, sales, and after-sales services to ensure the smooth operation of the production line and provide technical support.

In addition, we also have a bread production line. Please contact us for more information and a quote! WhatsApp/Phone: +86 13838385752.