The quality of your product and its essential ingredients are paramount in the food manufacturing industry. In chocolate production, cocoa powder and cocoa butter are the most fundamental ingredients. Investing in a hygienic and reliable cocoa powder production line is a crucial decision for manufacturers. Contact us today! WhatsApp/Phone: +86 13838385752.

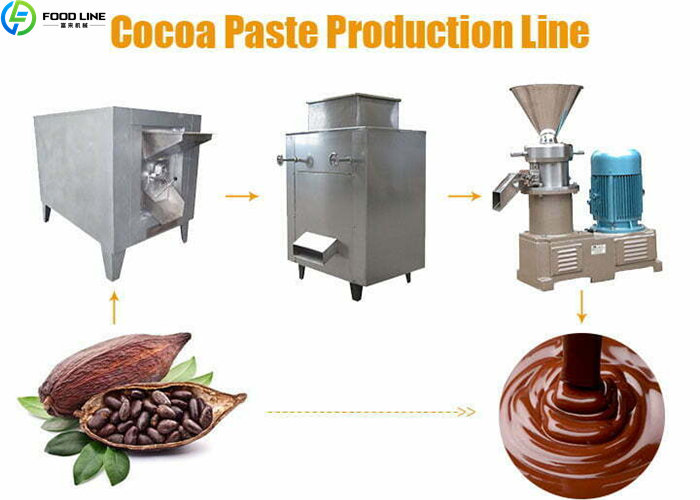

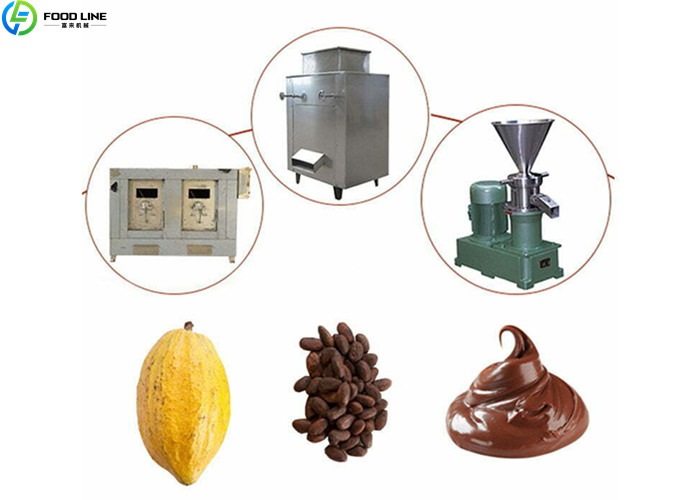

Cocoa Butter Production Line Overview

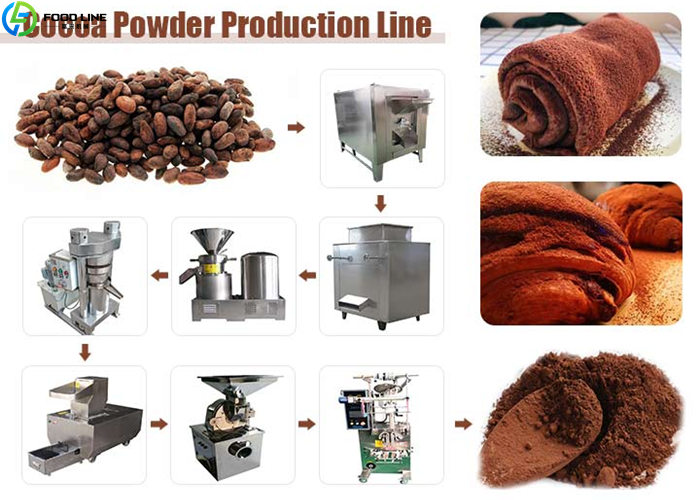

A cocoa powder production line is an integrated system that transforms raw cocoa beans into cocoa paste. The process involves several sequential steps, each handled by specialized machinery to ensure high standards of hygiene and yield. Our lines process up to 500 kilograms of beans per hour, incorporating roasting, cooling, aspiration, grinding, storage, and pressing.

Cocoa Powder Production Line Equipment

Cocoa Bean Drum Roaster

This equipment is used for baking or drying materials. Its working principle is heat conduction and heat radiation.

The main materials are as follows: inner mesh plate, upper and lower hoppers, and outer shell are made of stainless steel. Transmission parts and main frame are made of carbon steel.

| Specification Category | Details |

|---|---|

| Dimensions | 5m × 2.5m × 1.8m |

| Gear Motors | 1.1 KW — 5 units |

| Heating Power | Electric Heating: 112.5 KW |

Furnace Front Conveyor Cooling Belt

A speed reducer is used.

Main materials: The mesh belt, gusset plates, stainless steel, and transmission frame are all made of carbon steel.

| Parameter | Specification |

|---|---|

| Motor Power | 1.1 KW |

| Speed Control | Variable Speed |

| Voltage | 380 V |

| Frequency | 50 Hz |

| Dimensions (L×W×H) | 6m × 0.6m × 0.65m |

Coffee Bean Elevator

A reduction motor is used to transport the coffee beans.

Materials: PVC belt, stainless steel gussets and hopper, carbon steel transmission frame.

| Parameter | Specification |

|---|---|

| Dimensions | 0.6m × 0.6m |

| Motor Power | 0.75 KW |

| Speed Control | Variable Speed |

| Voltage | 380 V |

| Frequency | 50 Hz |

Cocoa Bean Peeling Machine

This machine consists of a peeling roller, a vibrating screen, a fan, and a specific gravity separator. It features a rational overall layout and reliable operation. Its operation process is simple and its performance is stable.

Material: Food-contact parts and frame: 201 stainless steel, transmission parts: carbon steel.

| Parameter | Specification |

|---|---|

| Output Capacity | 500 KG/H |

| Motor Power | 0.75 KW |

| Fan Power | 1.5 KW (with cyclone) |

| Dimensions (L×W×H) | 140cm × 70cm × 240cm |

| Weight | 160 kg |

Conveyor Picking Belt

Uses a speed-adjustable reducer.

Materials: PVC belt, gusset plate, stainless steel, transmission frame made of carbon steel.

| Item | Specification |

|---|---|

| Power | 1.1 KW |

| Operating Speed | Adjustable |

| Voltage | 380 V |

| Frequency | 50 Hz |

| Length | Customized according to workshop |

| Dimensions (W×H) | 0.9 × 0.85 meters |

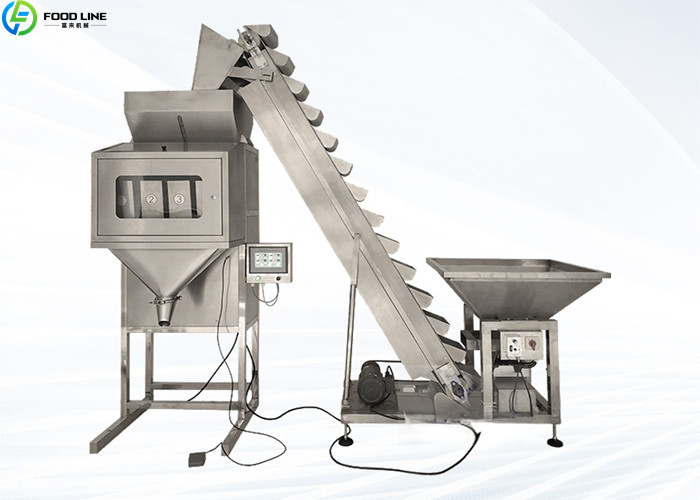

Storage Hopper

This device is used for quantitatively discharging material through vibration.

Material: Hopper stainless steel, transmission frame carbon steel.

| Parameter | Specification |

|---|---|

| Vibration Power | 0.15 KW |

| Voltage | 380 V |

| Frequency | 50 Hz |

Cocoa Alkalization Tank

The function of this equipment is to stir and alkalize alkaline water.

| Item | Specification |

|---|---|

| Tank Material | 304 Stainless Steel |

| Inner Thickness | 1.5 mm |

| Diameter | 900 mm |

| Height | 1000 mm |

| Heating Power | 12 kW |

Cocoa Bean Grinder

Cocoa nibs are coarsely ground and then finely ground into cocoa paste. The fineness adjusts according to needs.

| Parameter | Specification |

|---|---|

| Processing Fineness | 2 – 100 μm |

| Dimensions (L×W×H) | 110 × 75 × 130 cm |

| Motor Power | 37 kW |

Cocoa Sauce Receiving Tank

After refining, join the materials.

| Parameter | Specification |

|---|---|

| Dimensions (L×W×H) | 600 × 650 × 600 mm |

| Capacity | 200 L |

| Material | Stainless Steel |

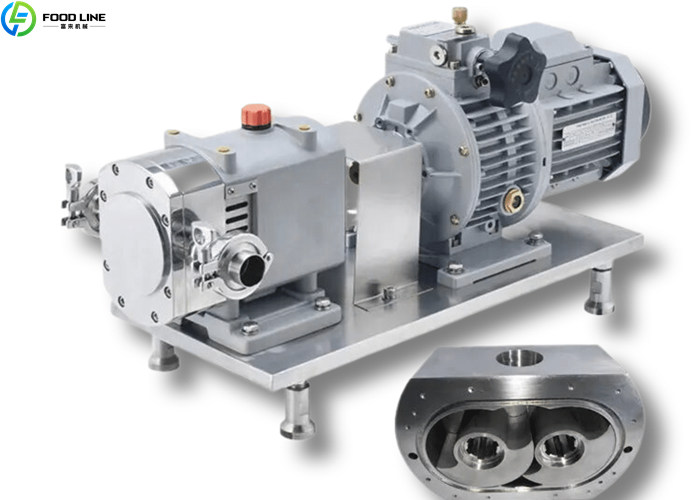

Paste Pump for Cocoa

| Parameter | Specification |

|---|---|

| Flow Rate | 5 m³/h |

| Head | 20 m |

| Power | 3 kW |

| Material | Food-grade Stainless Steel |

Mixing and Cooling Storage Tank

This equipment is used to cool down the ground sauce. The sauce flows through the tank, scraped synchronously by a scraper. If you use cooling water, you will need an external cooler.

| Parameter | Specification |

|---|---|

| Motor Power | 2.2 kW |

| Rotation Speed | 36 rpm |

| Operating Voltage | 380 V |

| Tank Diameter | 1300 mm |

| Tank Height | 1800 mm |

| Capacity | 1000 L |

Cocoa Butter Press Machine

The function of this equipment is to skim and extract the cocoa butter from the cocoa paste.

| Parameter | Specification |

|---|---|

| Working Pressure | 50 MPa |

| Working Thrust | 210 T |

| Cylinder Capacity | 150 kg/h |

| Weight | 2300 kg |

| Material (Mold) | SS 304 |

Free Quote! WhatsApp/Tel: +86 13838385752.

Cocoa Powder Production Line Characteristics

- Automation: From dosing to pumping, the production line reduces manual intervention and improves efficiency.

- Hygienic Design: All food-contact surfaces are constructed of stainless steel (grades 201 or 304). This meets food safety standards and is easy to clean and maintain.

- Energy-saving Options: Electric or gas heating options are available. The manufacturer can select the most appropriate solution based on local energy costs.

- Design: The production line consists of independent machines that can be configured to suit available space. It is easily expandable or upgradeable.

- Control: Utilizes a variable-speed motor and temperature control system. Operators can adjust process parameters to suit different bean characteristics.

Advantages of Cocoa Butter Production Line

- High Capacity: The 500 kg/h capacity design meets the needs of small, medium, and large producers.

- Product Quality: Uniform roasting, efficient dehulling, and precise grinding produce high-quality cocoa powder and cocoa butter.

- Reliability: Industrial-grade components, such as a geared motor and a sturdy carbon steel frame, ensure long-lasting operation.

- Operation: Trained operators can easily manage the entire process.

Production Line Workflow

- Roasting: Raw cocoa beans are roasted at a controlled temperature in a drum roaster.

- Cooling and Conveying: The conveyor belt cools the beans. And then an elevator transports them to a dehulling machine.

- Dehulling and Sorting: The dehulling machine crushes the beans and separates the shells, resulting in cocoa nibs. Sorting typically follows to ensure purity.

- Feeding and Grinding: Cocoa nibs are fed steadily through a metered hopper into a coarse grinder and then into a fine grinder, creating cocoa paste.

- Storage and Pumping: Cocoa liquor is pumped into insulated storage tanks.

- Pressing: The system pumps cocoa liquor into a press, applying pressure to separate the cocoa butter.

- Final Processing: The cocoa paste is collected and stored, ready for use in chocolate production or other applications.

Why Choose Foodline Equipment

- Expertise: We have 20 years of experience in machinery manufacturing and a professional design team.

- Quality Assurance: We use high-quality materials to build our equipment, ensuring its longevity and stability.

- Customization: We offer customized solutions tailored to your needs.

- After-Sales Support: We provide 24-hour response time from pre-sales to after-sales service to ensure the normal operation of your production line.

Investing in a complete cocoa butter production line is an important step in improving profitability in the food manufacturing industry. In addition, we also have a cashew nut production line. If you’re interested, please contact us! WhatsApp/Phone: +86 13838385752.