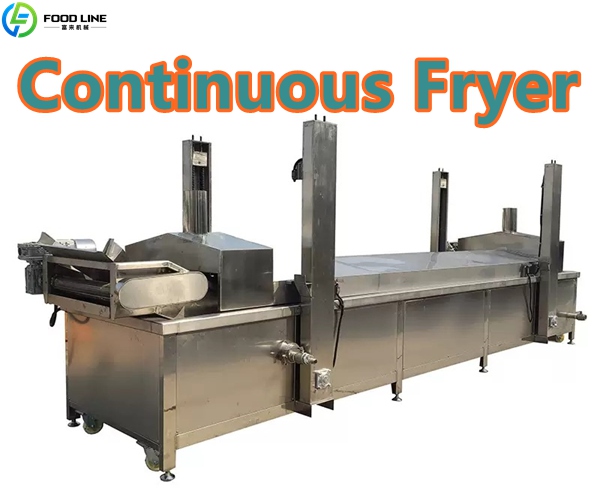

Deep frying is an important process in the food industry. Therefore, an increasing number of food factories are using continuous fryers to improve production efficiency and ensure consistent product quality. Welcome to get a quote! WhatsApp/Phone: +86 13838385752.

Commercial Continuous Fryer Applicable Products

- Extruded snacks: such as French fries, potato chips, rice cakes, corn on the cob, etc.

- Meat products: chicken nuggets, popcorn chicken, fish fillets, pork chops, meatballs, etc.

- Flour products: spring rolls, rice crackers, fried dough twists, fried dough sticks, etc.

- Vegetable products: pumpkin strips, sweet potato strips, lotus root slices, carrot slices, etc.

Parameters of Continuous Fryer

| Model | FL – 8500 |

|---|---|

| Overall Dimensions | 8500 mm * 2000 mm * 2200 mm |

| Mesh Belt Width | 800 mm |

| Heating Method | Electric Heating |

| Power | 420 kW |

| Frying Time Range | 20 seconds – 100 seconds (Variable Frequency Speed Control) |

| Frying Temperature Range | Ambient Temperature — 230°C |

| Material | SUS304 Stainless Steel |

| Frying Zone Height | 10 mm — 100 mm |

Contact Us! WhatsApp/Phone: +86 13838385752.

Features of Continuous Frying Machines

- Double-layer Mesh Belt Design: The upper and lower double-layer mesh belt conveyor structure effectively secures food. This design prevents products from floating, curling, or deforming in the oil.

- Speed Control System: Operators can adjust the conveyor speed using a frequency converter according to the characteristics of different products.

- Residual Oil Filtration System: Equipped with a residual oil collection system at the bottom of the equipment, it continuously filters residual oil.

- Temperature Control System: An advanced temperature control system maintains the oil temperature within the set range with minimal fluctuations.

- Lifting System: The entire machine adopts an automatic lifting structure, allowing for the overall lifting of the mesh belt and oil tank.

- Stainless Steel Structure: The equipment is made of corrosion-resistant stainless steel, meeting food processing hygiene standards.

Advantages of Industrial Continuous Frying Machine

- Efficiency: Compared to traditional frying methods, the continuous fryer enables uninterrupted operation, significantly increasing output and making it suitable for medium to large-sized food enterprises.

- Product Quality: Constant oil temperature and consistent frying time ensure uniform product color, taste, and doneness.

- Cost: Fully automated operation eliminates the need for frequent manual turning or monitoring, reducing labor intensity and employment costs. An automatic filtration system extends oil lifespan, resulting in long-term savings in raw material costs.

- Safety: Stainless steel construction, automatic temperature control, and automatic cleaning ensure excellent overall hygiene.

- Sustainable Production: Continuous production saves time and increases factory capacity.

FAQ

No, the main unit does not need to be replaced. Simply adjust parameters such as belt speed and temperature to accommodate various food products.

You can choose electric heating, gas heating, diesel heating, or thermal oil heating according to your requirements.

Yes. This equipment supports hamburger patty production lines, fully automatic chicken nugget production lines, fully automatic meatball production lines, and popcorn chicken production lines.

Why Choose Foodline Machinery?

- Professional Experience

- CE Certification

- After-Sales Service

- Export Experience

If you would like to learn more about continuous fryers, please feel free to contact us for a quote and information! Our fryers can be integrated into a French fry production line. WhatsApp/Phone: +86 13838385752.