Corn flakes, as a convenient, nutritious, and fiber-rich food, are an important choice for consumers. Corn flake production lines are key equipment for producing high-quality corn flakes. Get a free quote! WhatsApp/Phone: +86 13838385752.

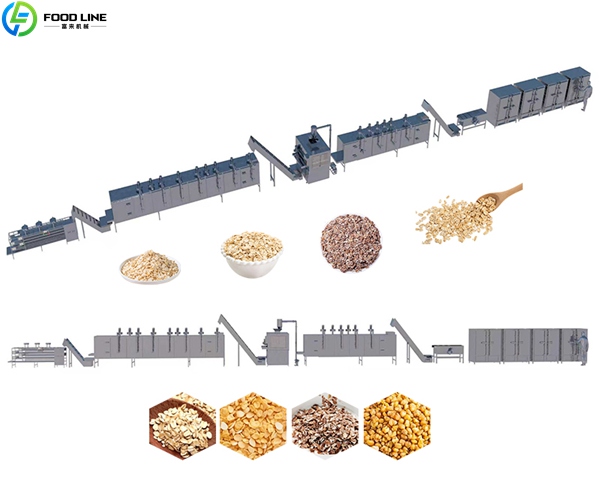

Overview of Cereal Production Line

This production line processes grains such as corn and oatmeal to produce oatmeal that is uniformly shaped, crispy, and nutritious. The entire line integrates multiple processes including raw material handling, drying, cooling, and packaging. It can efficiently and consistently produce high-quality oatmeal products.

With the increasing demand for healthy foods, oatmeal has become a representative of nutritious breakfasts, especially among young people and busy urban dwellers, where there is significant market demand. As a core piece of equipment in this industry, the oatmeal production line inevitably plays a crucial role.

Parameters of Corn Flakes Processing Line

| Equipment | Max Capacity / Output | Power | Weight | Dimensions (L×W×H) / Other Specs |

|---|---|---|---|---|

| Mixing Tank | 900 L | 4 kW | 180 kg | φ1150*2070 mm |

| Feed Pump | 5 m³ | 3 kW | – | Caliber: 40 mm |

| Impact Grinder | – | 11 kW | 230 kg | 990*440*1050 mm |

| Storage Tank | 900 L | 3 kW | 170 kg | φ1150*2070 mm |

| Feed Pump | 5 m³ | 3 kW | – | Caliber: 40 mm |

| Flake Drum Dryer | 10-12 ton/24h | 22 kW | 25 ton | 5200*3600*4800 mm Roller: φ2000*4000 mm Steam Pressure: 0.6-1.0 MPa Steam Consumption: 300 kg/h |

| Primary Crusher | – | 3 kW | 480 kg | 5750*540*1470 mm |

| Inclined Conveyor | – | 3 kW | 230 kg | 4020*406*500 mm |

| Flake Pelletizer | 450 kg/h | 3 kW | 120 kg | 1320*786*2010 mm |

| Cyclone Grinding Unit | 350-400 kg/h | 11 kW | – | 3500x820x2500 mm Spindle Speed: 4000 r/min Fineness: 60-80 mesh Material: 304 Stainless Steel Power Supply: 3-phase 380V 50-60Hz |

Working Principle of Cereal Making Machine

- Raw Material Processing: Corn or other grains are fed into the raw material processing system for preliminary processing such as washing, peeling, and grinding.

- Grinding and Extrusion: The processed raw materials are transformed into powder through a grinding system and then enter an extruder. The extruder uses high temperature and pressure to expand the raw materials, making them crisp.

- Seasoning and Baking: The extruded oatmeal enters the seasoning system where seasoning ingredients are added. It then enters a baking machine for high-temperature baking.

- Cooling and Cutting: The baked oatmeal passes through a cooling system to rapidly cool it, maintaining its crispness and texture. Simultaneously, the cooled oatmeal is cut into sizes and shapes to meet market demands.

- Packaging: The finished oatmeal is packaged by an automated packaging system to ensure product quality.

Features of Cereal Processing Line

- High Efficiency: The cereal production line utilizes an advanced automated control system, significantly improving production efficiency. Compared to traditional manual production, mechanized production can complete more production tasks in a shorter time.

- Output: The production line can be adjusted to meet different market demands. For example, it can produce cereal products in different flavors and shapes to satisfy diverse consumer preferences.

- Automation: Modern cereal production lines use advanced PLC control systems, which significantly reduce the need for manual intervention during production. This approach lowers labor costs and minimizes human error.

- Energy Saving: Current cereal production lines are optimized for energy conservation, reducing energy consumption. They also use environmentally friendly materials, minimizing pollution during production.

- Safety: The entire production line is designed to meet international safety standards, ensuring the safety of personnel during production. The production line boasts high stability, a low failure rate, and guarantees continuous production.

Advantages of Cereal Production line Machines

- Quality: The cereal production line utilizes precise technical controls to ensure consistent quality in every batch of cereal. The cereal is crispy and has a uniform appearance.

- Ingredients: In addition to corn, the production line can also process other grains such as rice, wheat, and oats. This increases product variety.

- Cost: It saves on labor costs, improves production efficiency, and reduces the production cost per unit.

- Market: With the increasing consumer demand for healthy and nutritious breakfasts, the cereal industry has enormous market potential. Investing in a cereal production line is a very promising option.

Why Choose Foodline Equipment?

- Professional R&D team

- CE certification

- After-sales service

- Export experience

In addition to this, we also have a cookie production line. If you are interested in our cereal production line, please feel free to contact us for more information! WhatsApp/Phone: +86 13838385752.