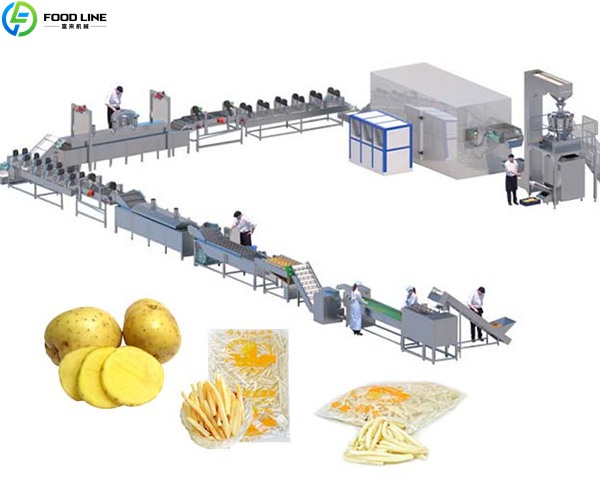

Are you looking for a dependable, high-yield solution to expand your snack food business? Our 200kg French fry processing line is designed to help manufacturers like you produce high-quality French fries efficiently and consistently. Whether you’re building a new facility or upgrading an existing operation, our frozen French fry production line can meet your needs. Welcome to consult for more information! WhatsApp/Phone: +86 13838385752.

Equipment in French Fries Production Line

| Device Name | Power | Dimensions |

| Elevator | 0.75kw/380v/50Hz | 2000*800*1600mm |

| Cleaning and peeling machine | 4.75kw/380v/50Hz | 3400*900*1500mm |

| Picking line | 0.75kw/380v/50Hz | 3000*900*900mm |

| Potato chip slicer | 1.5kw/380v/50Hz | 950*800*950mm |

| Rinsing line | 5kw/380v/50Hz | 5000*1600*1200mm |

| Blanching line | 70kw/380v/50Hz | 5500*1200*950mm |

| Vibrating screen | 0.16KW/380V/50Hz | 2000*1250*1000mm |

| Air drying and dehydration machine | 15kw/380v/50Hz | 4000*1200*1400mm |

| Elevator | 0.75kw/380v/50hz | 1500*800*1300mm |

| Gas Heating Frying Line | 203kw/380v/50Hz | 8000*1200*2400mm |

| Cooling line | 8kw/380v/50Hz | 6000*1200*1600mm |

| Elevator | 0.75kw/380v/50Hz | 2000*800*2200mm |

| Drum seasoning machine | 1.5kw/380v/50hz | 2400*1000*1600mm |

| Vertical packaging machine | 5kw/380v/50Hz | 4000*2500*3500mm |

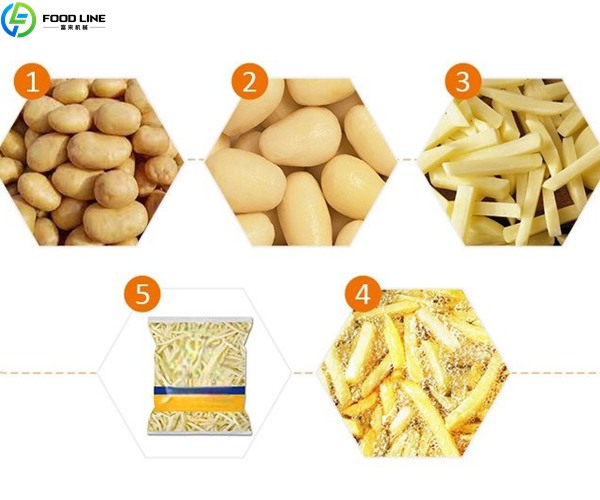

French Fry Production Process Breakdown

Here’s a step-by-step overview of how the frozen French fries production line operates:

- Lifting and Feeding: Fresh potatoes are fed into the production line via a lifting conveyor, ensuring continuous and regulated input to the cleaning system.

- Washing and Peeling: A combination washer and peeler removes surface dirt and skin efficiently, preparing the potatoes for cutting without compromising their quality.

- Sorting and Trimming: After peeling, the potatoes are inspected for blemishes or defects. Trimming ensures consistent product specifications before slicing.

- Cutting: A high-precision slicer cuts the potatoes into uniform strips, ensuring consistent shape and size. This is crucial for even heating during frying.

- Rinsing: The cut potato strips are rinsed to remove excess starch, which helps prevent sticking and ensures a crispy texture after frying.

- Blanching: The potatoes are quickly blanched to preserve their color, improve taste, and inhibit enzyme activity. This step is crucial for long-term storage and quality control.

- Air Chilling and Dehydration: After blanching, the fries are air-chilled and partially dehydrated to remove surface moisture. This step helps reduce oil absorption during frying.

- Frying: Using oil-water separation technology, the fries are evenly fried to a golden and crispy texture. This method extends the shelf life of the oil and reduces impurities.

- Air Chilling and De-oiling: Efficient air chilling removes excess oil, preserving flavor while reducing the greasy feel of the final product.

- Seasoning: The fries pass through a seasoning drum, evenly distributing the seasoning and allowing for customization to consumer preferences.

- Packaging: The final product is weighed and packaged using an automatic packaging machine, ready for sale or freezing.

Key Features of the French Fries Processing Line

- Fully Automated Operation: Each process is precisely controlled to maintain product quality and hygiene standards. From feeding to packaging, automated processes ensure consistent output and reduce the risk of human error.

- Modular and Scalable Design: The 200 kg/hour configuration can be customized to your specific needs, with the option to add or upgrade individual modules as production demands grow.

- Food-Grade Construction: All equipment is constructed of stainless steel and complies with international food safety standards. To ensure long-term durability and easy maintenance.

- Energy-Saving and Environmentally Friendly: The line utilizes intelligent temperature control and a water-oil hybrid frying system to reduce energy consumption and extend the life of the oil.

Advantages of Potato Chips Production Line

- High-Quality Output: Our systems deliver uniform slicing, frying, and seasoning. The end product meets market standards for taste, texture, and appearance.

- Reduced Labor Costs: High automation and minimal operator training requirements significantly reduce the need for manual operation.

- Suitable for frozen and fresh markets: Whether your goal is to serve the frozen chips market or ready-to-eat products, this line will meet your target business model.

- Stable System Operation and After-Sales Guarantee: All equipment utilizes high-quality motors, temperature control modules, and transmission systems, and has undergone multiple rounds of testing to verify its stable performance. We offer a one-year warranty and technical support, and our after-sales service is highly recognized by customers in over 20 countries worldwide.

Why Choose Foodline Machinery

- Extensive Manufacturing Experience: With years of expertise in food processing equipment, we understand production process challenges and provide practical solutions.

- Customization and Technical Support: We offer tailored configurations and comprehensive after-sales support, including installation, training, and troubleshooting.

- Global Export Capabilities: Our products have been successfully used in over 20 countries, helping manufacturers achieve global scale.

- Strict Quality Assurance: Each component is rigorously tested to ensure performance, durability, and compliance with international food processing standards.

Don’t let outdated equipment limit your productivity. Achieve consistency, efficiency, and profitability with a fully automated French fry processing line. Whether you’re entering the frozen French fry production market or expanding existing capacity, our solutions can help. Contact us today to learn how we can tailor a solution for your business. Let us turn your ideas into reality! WhatsApp/Phone: +86 13838385752.

In addition, we have production lines with different capacities, including 30kg, 50kg, 70kg, and 100kg French fry production lines.