Large-scale vacuum freezers are essential equipment in the food, biopharmaceutical, health product, and agricultural product industries. Freeze-drying technology is a crucial process for enhancing product value, extending shelf life, and improving nutrient retention. A high-efficiency, highly stable industrial freeze dryer is key equipment for enterprises to expand production capacity and enhance product competitiveness. Feel free to contact us! WhatsApp/Phone: +86 13838385752.

Industrial Freeze Dryer Overview

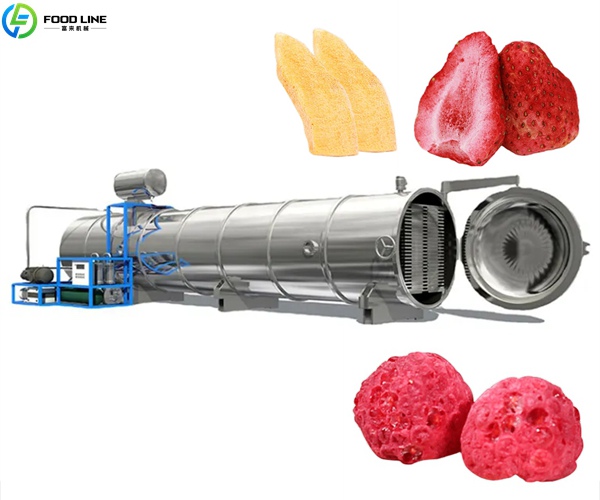

Large-scale freeze dryers are high-end processing equipment that dehydrates materials under low-temperature, vacuum conditions through the principle of sublimation. Compared to traditional drying methods, they can preserve the nutritional components, biological activity, taste, and appearance of materials to the greatest extent. Furthermore, the products can be stored at room temperature for extended periods, making them an indispensable core production equipment in the modern food, biological, and pharmaceutical industries. Our industrial freeze dryer machines range from 0.5㎡ to 200㎡, meeting the needs of experimental, pilot-scale, and factory-scale production.

Parameters of Industrial Scale Freeze Dryer

| Model | FL – F10 |

|---|---|

| Drying Area per Drying Chamber | 10 m² |

| Loading Capacity (Meat Products) | Approx. 150 KG |

| Loading Capacity (Agricultural Products) | Approx. 100 KG |

| Overall Dimensions (m) L x W x H | 5.8 x 1.7 x 2 |

| Number of Trays per Drying Chamber | 24 pcs x 2 sets |

| Tray Carts | 1 unit x 2 sets |

| Tray Dimensions | 610 x 710 x 37 mm |

| Shelf Temperature | 30°C ~ 120°C |

| Number of Shelves | 26 plates |

| Chamber Material | Stainless Steel |

| Cold Trap Temperature | -40°C ~ -50°C |

| Total Installed Power | 34 KW |

| Working Vacuum Degree | 10 Pa ~ 130 Pa |

| Heating Method | Electric Heating |

| Working Pressure in Drying Chamber | Minimum 1 MPa |

| Chamber Design Pressure | -0.1 MPa |

| Operating Ambient Temperature | ≤ 40°C |

Products Applicable to Large Freeze Dryers

Food Products

- Vegetables, fruits, fruit powders, flowers

- Meat, poultry, aquatic products

- Instant foods, ready-to-eat foods, condiments

- Coffee, dairy products, grain products

Medicinal Herbs and Biological Products

- High-value materials such as Chinese medicinal herbs, Cordyceps sinensis, sea cucumber, and deer antler

- Biological products and bioactive substances

- Raw materials for health products and nutritional supplements

Chemicals

- Chemical powders

- High-value functional raw materials

- Heat-sensitive products

Contact Us! WhatsApp/Phone: +86 13838385752.

Working Principle of Freeze Dryer

- Pre-treatment stage: Different materials require different pre-treatment methods. For example, vegetables need to be sorted, washed, cut, and blanched. Fruits require special attention to preserve their color. The correctness of pre-treatment directly affects the final freeze-dried quality.

- Pre-freezing: Freezing methods can be quick-freezing or self-evaporation freezing. However, food products usually use quick-freezing to ensure quality and texture.

- Sublimation drying: After the material enters the drying chamber, under low pressure, the ice crystals in the material directly sublimate into water vapor. The heating system provides the latent heat required for sublimation to the material via radiation. The vacuum system maintains the low pressure. The refrigeration system traps water.

- Post-treatment: Freeze-dried foods have a porous structure and are easily hygroscopic. Therefore, vacuum packaging or nitrogen purging protection is required.

Features of Large Freeze Dryers

- Multi-system structure: The equipment integrates four major systems: refrigeration, vacuum, heating, and electrical control, ensuring a stable and reliable freeze-drying process.

- Radiant heating: The heating plates transfer heat to the material radiantly, resulting in uniform heat distribution and accelerating sublimation.

- Cold trap and defrosting: Utilizing an advanced water-capturing cold trap, it rapidly freezes water vapor and achieves defrosting.

- Vacuum system: The vacuum unit supports oil-water separation, ensuring stable vacuum levels and providing an optimal environment for sublimation.

- Parallel refrigeration system: Employing a multi-path parallel cooling system, it provides on-demand cooling, resulting in more stable operation and significant energy savings.

- Control system: Artificial intelligence control enables high-precision temperature, vacuum, and time control; the user interface is user-friendly, and operation is reliable.

- Production: A single unit can cover an area of up to 200 square meters, suitable for large factories and mass production needs.

Advantages of Industrial Freeze Dryer Machine

- Nutritional Retention: Freeze-drying technology dehydrates at low temperatures, preserving the nutritional structure and maintaining high levels of bioactivity.

- Appearance: Freeze-dried foods do not shrink or deform, exhibiting a porous, sponge-like structure with excellent rehydration properties.

- Storage at Room Temperature: Freeze-dried products can be stored at room temperature, resulting in lower costs compared to refrigerated foods.

- Drying Time: Optimized freeze-drying curves and precise control of sublimation temperatures effectively shorten the freeze-drying cycle.

- Transportation Costs: Freeze-dried products are lightweight and do not require cold chain transportation, reducing operating costs.

FAQ

Suitable for food, biopharmaceutical, health product, and agricultural processing industries.

Equipment space ranges from 0.5㎡ to 200㎡, meeting the needs from small-scale trials to large-scale production.

Depending on the material, the cycle time is typically 8–24 hours.

About Foodline Equipment

- CE Certification

- After-sales Service

- Professional R&D Experience

If you would like to learn more about freeze dryers, please feel free to contact us! In addition, we also offer continuous frying machines. WhatsApp/Phone: +86 13838385752.