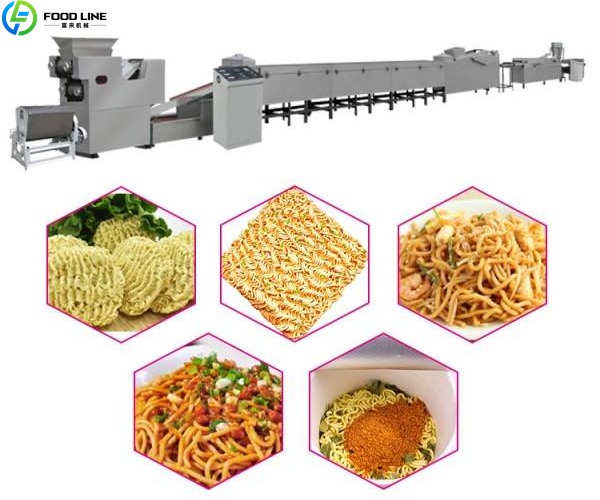

An instant noodle production line is a cluster of automated equipment that integrates processes such as dough mixing, cooking, rolling, steaming, cutting, frying, cooling, and packaging. Through the coordinated operation of these units, raw materials such as flour, water, and salt transform into instant noodles. Its core advantages lie in its high degree of automation, standardized production, and scalable production capacity. It is suitable for industrial production of a wide range of products.

Instant Noodle Production Line Core Equipment Parameters

Raw Material Pretreatment Unit

Brine mixing tank

| Tank Volume | 1000 Liters |

| Reducer & Motor | Helical gear reducer with brand-name motor |

| Power | 1.5 kW |

| Agitator Speed | 280 rpm |

| Water Level Gauge | Flip plate type level gauge |

| Material (Tank, Shaft) | SUS304 Stainless Steel |

| Material (Pipes, Valves) | Sanitary Grade SUS304 |

| Overall Dimensions | 1000 (L) x 1000 (W) x 1000 (H) mm |

Dough Processing Unit

Double-shaft dough mixer

| Capacity | 50 kg/batch (flour) |

| Structural Features | Double-shaft, Horizontal |

| Motor Power | 5.5 kW |

| Material (Food Contact Parts) | SUS304 Stainless Steel (Barrel, Mixing Rods, Hopper, etc.) |

| Water Addition Method | Manual spray pipe |

| Dimensions (L×W×H) | 1500 × 600 × 850 mm |

| Weight | Approx. 250 kg |

Food conveyor belt

| Length | 6 meters |

| Conveyor Belt | Food Grade |

| Frame | Stainless Steel |

| Power | 0.37 kW |

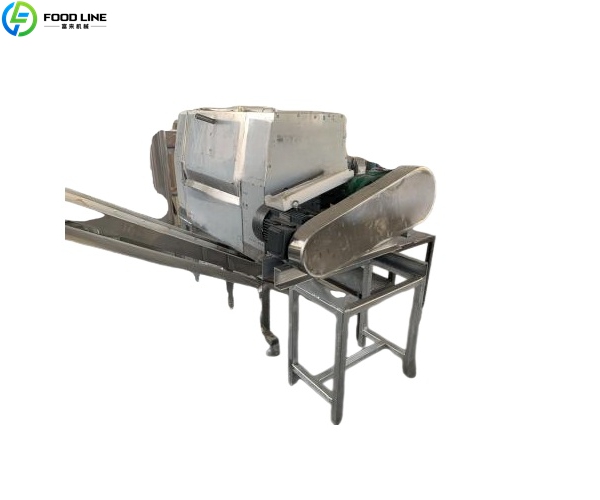

Molding Unit

Industrial-grade noodle pressing machine

| Material (Pressure Rollers) | Chill Hardened Alloy Cast Steel |

| Material (Cover/Guard) | Stainless Steel |

| Number of Pressure Rollers | 6 sets |

| Roller Width | 300 mm |

| Roller Configuration (Diameter x Quantity) | φ126 mm x 2, φ168 mm x 1, φ126 mm x 3 |

| Power & Control | 5.5 kW, Variable Frequency Speed Control |

| Dimensions (L×W×H) | 2800 × 600 × 1200 mm |

Frying and Post-Processing Unit

Large frying machine

| Dimensions (L×W×H) | 8000 × 1300 × 1850 mm |

| Included Systems | Heating system, Automatic temperature and oil level control |

| Lifting Mechanism | Automatic and manual lifting for the oil tank |

| Material (Oil Tank) | Carbon Steel |

| Heat Exchanger | 50 m², Carbon Steel |

| Total Power | 0.75 kW |

| Weight | Approx. 4500 kg |

Horizontal Food Oil Storage Tank

| Material | Carbon Steel |

| Dimensions (LWH) | 2300 * 800 * 2100 mm |

| Total Capacity | 2000 Liters |

| Configuration | 1500L + 500L (with partition) |

| Features | • Includes support stand and ladder • Equipped with auto-control heating system (prevents oil solidification) • Automatic oil level control |

Features of Noodle Production Line

Materials and Hygiene

Core food-contact components, such as the brine mixing tank, twin-shaft dough mixer, and noodle steamer. These are made of SUS304 food-grade stainless steel. This ensures a pollution-free production process that complies with food industry hygiene standards. Non-contact components are made of SUS201 stainless steel or high-quality carbon steel, balancing durability and cost control.

Design

The production line utilizes a modular unit structure, allowing flexible configuration of equipment based on production capacity and site layout. The number of steamer stages, fryer length, and packaging units can be adjusted to meet varying production needs.

Intelligent System

Equipped with a full PLC control system and touchscreen interface. It monitors key parameters such as temperature, speed, and oil level in real time, enabling inter-process coordination.

Energy Saving

The equipment integrates energy-saving technologies such as variable frequency drive, waste heat recovery, and intelligent temperature control. For example, the fryer’s heat exchanger recovers waste heat for preheating. And the air cooler’s fan power is adjusted on demand. Overall energy consumption is lower than traditional production lines, reducing costs over the long term.

Free Quote! WhatsApp/Tel: +86 13838385752.

Advantages of Fried Instant Noodle Production Line

Production Capacity

This production line can produce 40,000 packages (75g/piece) in 8 hours, over 10 times the efficiency of traditional manual production. This allows for rapid response to market orders, helping companies secure large orders.

Quality

Automated production eliminates variability associated with manual operation, ensuring highly consistent noodle weight, thickness, and degree of frying. This prevents issues like inconsistent taste, lumps, and undercooked noodles, helping companies cultivate a high-quality brand image.

Management Costs

The production line is fully automated, requiring only a few operators to complete the entire process from raw material input to finished product output. This reduces labor recruitment, training, and management costs, while also eliminating the safety risks of manual operation.

Product Categories

By adjusting the recipe, molds, and process parameters, the production line can produce a variety of products, including traditional fried noodles, non-fried noodles, children’s nutritional noodles, and multi-grain noodles. This helps companies quickly capture market share and increase profitability.

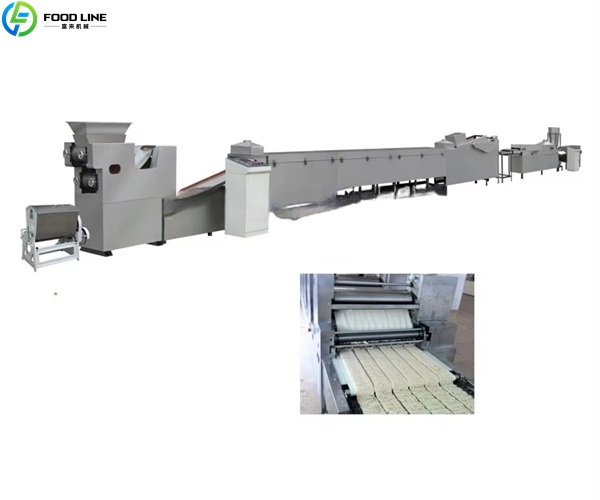

Instant Noodle Production Process

Raw Material Pretreatment

- Brine Preparation: The brine preparation process adds salt and water to the mixing tank in the correct proportions and stirs them to form a uniform brine.

Dough Processing

- Dough Mixing: Flour and salt water enter a twin-shaft dough mixer, which kneads them into dough.

- Maturation: The circular kneading machine receives the wet dough from the conveyor and kneads it to develop the gluten network.

- Rolling: The matured dough enters a dough sheeter, where it is repeatedly rolled by six sets of rollers to form the dough skin.

Steaming and Cutting

- Steaming and Gelatinization: The dough enters a three-stage steamer for gelatinization.

- Dough Block Cutting: The gelatinized dough is cut into standard dough blocks by a square cutter.

Frying and Post-Processing

- Frying: The dough pieces enter the fryer and are formed in the oil.

- Cooling and Sorting: An air chiller rapidly cools the fried dough pieces, and then a sorting machine neatly arranges them.

- Storage and Transportation: The sorted dough pieces are transported via conveyor to the packaging stage.

About Foodline Machinery

- Equipment Quality: All equipment is CE certified.

- Customized Services: We offer customized solutions based on your production capacity needs, site size, and product offerings.

- After-Sales Support: We provide equipment installation and commissioning, operator training, and 24-hour after-sales support.

With efficient conversion from raw materials to finished products and dual guarantees on quality and cost, our automated instant noodle production line is a wise choice for food companies to achieve standardized production. In addition, we also have French fries and potato chips production lines. If you want more information, please feel free to contact us! WhatsApp/Phone: +86 13838385752.