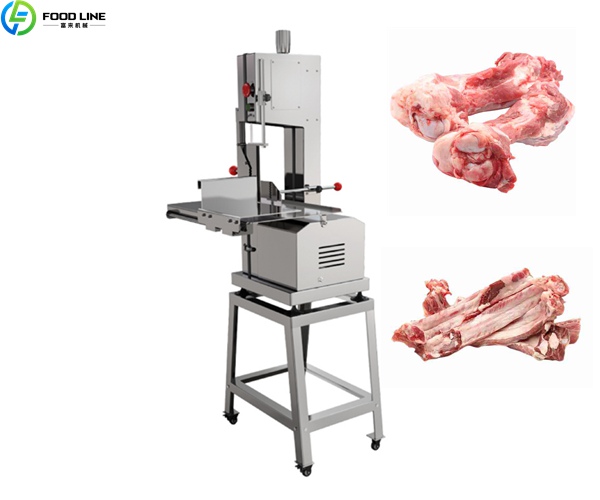

Modern catering, meat processing, and supermarkets are experiencing a growing demand for efficient, safe, and reliable bone and meat cutting tools. The 210 bone saw, with its professional design and outstanding performance, is an ideal choice for small and medium-sized meat processing and catering operations. Whether it’s large, tough bones or frozen meat requiring precise cuts, the 210 bone saw can easily sever them.

If you want to get more information about this product, please contact us! WhatsApp/Phone: +86 13838385752.

Specifications of Meat Cutting Saw Machines

| Parameter | Specification |

|---|---|

| Product Name | FL-210 |

| Cutting Height | 0–210mm |

| Motor Power | 650W (Pure Copper) |

| Cutting Width | 5–120mm |

| Rated Voltage | 220V (Customizable) |

| Machine Weight | 26kg |

| Blade Speed | 300m/min |

| Platform Size | 475×360mm |

| Blade Model | 1300mm |

Features of Bone Sawing Machines

- The 210 bone saw features a compact tabletop design, saving space and making it convenient for small or medium-sized kitchens or back kitchens. Its sturdy and durable carbon steel body, paired with a stainless steel worktop, is rust-resistant and corrosion-resistant, meeting food hygiene requirements. The worktop measures 470mm long and 360mm wide, ensuring ample cutting space while also being easy to carry and move.

- The machine’s overall height is 780mm, a scientifically designed, ergonomic design that minimizes fatigue even during long hours of work. With a cutting height of 210mm and a cutting width of 120mm, it can accommodate most large bones, frozen meat, and fish portioning needs. The saw blade operates smoothly and maintains a sharp edge, making it easy to cut large bones and minimize meat waste.

- In addition, the machine is equipped with a safety push-plate, a saw blade adjustment knob, motor cooling vents, and a one-touch control switch, fully demonstrating its commitment to safety.

Advantages of Bone Saw Equipment

- Compared to traditional manual cutting, the 210 bone saw offers significant efficiency advantages. It can cut multiple pieces of frozen meat or bone per minute, significantly reducing labor costs and operation time. Furthermore, the smooth cut surface reduces meat residue, ensuring the appearance and hygiene of the food.

- The 210 bone saw’s blade can be quickly disassembled and installed, making replacement easy and maintenance simple. The carbon steel body and stainless steel worktop provide excellent rust resistance and extend the machine’s service life.

- The stable power output and sturdy transmission structure ensure that the machine will not shake or jam during continuous operation, preventing efficiency losses and reducing safety hazards during operation.

Product Usage Procedure

To help you quickly get started with the meat cutting saw machine, the following standard operating procedures are provided for your reference:

- Preparation: Place the machine on a stable, sturdy work surface. Turn on the power and check that the switch is responsive and that the saw blade is properly tensioned.

- Safety Check: Check the safety push plate, guard, and protective shield to ensure they are in place and not loose or missing.

- Adjust the Saw Blade: Use the blade adjustment knob to adjust the blade tension and height according to the thickness of the aggregate.

- Place the Aggregate: Place the aggregate to be cut on the stainless steel workbench, keeping it level and close to the edge.

- Start Cutting: Turn on the switch and use both hands to push the aggregate, slowly pushing with the safety push plate, allowing the saw blade to complete the cut.

- Cleaning After Cutting: After cutting, turn off the power and promptly remove the saw blade for cleaning to prevent residue buildup and potential health issues.

Applicable Scenarios of 210 Bone Saw Machine

- Frozen food processing plants

- Supermarket cutting and processing areas

- Delicatessens/butcher shops

- Fish processing centers

- School and office cafeterias

- Small and medium-sized slaughterhouses

Its table-top structure makes it easier to arrange flexibly in various operating spaces, allowing users to perform a variety of meat and bone cutting operations.

Why Choose Foodline Machinery?

We have years of experience and service expertise in the food machinery industry, committed to providing customers with the highest-quality products and the most professional solutions. Reasons to choose us include:

- Reliable Qualifications: Multiple certifications ensure consistent quality.

- Direct Factory Supply: No markups, high value for money.

- Technical Support: Remote technical support and comprehensive process assurance.

- Strong Customization Capabilities: Customize models to meet your specific needs.

- Complete After-Sales Service: 24/7 response time, readily available spare parts, and rapid response.

No matter what your needs are, we can provide you with a bone sawing machine that meets the standards, is easy to operate, safe and durable, helping you to easily improve production efficiency and reduce labor losses. Welcome to contact us for quotes and product information! WhatsApp/Phone: +86 13838385752.