A powder bagging machine is a device used for packaging powdered materials. It is widely used in the food, seasoning, beverage, and daily chemical industries. This equipment performs multiple processes, including bag making, metering, filling, and sealing. Request a quote! WhatsApp/Phone: +86 13838385752.

This powder packaging machine uses a strip-type packaging format, suitable for small-dose packaging needs. It supports adjusting the bag shape for different product specifications.

Application Areas of Powder and Granule Packaging Machines

- Beverage industry: Instant coffee powder, fruit-flavored instant drinks, functional beverage powders.

- Seasoning industry: Pepper powder, chili powder, compound seasonings.

- Sauce products: Small-dose liquid sauces, seasoning sauces.

- Other areas: Health foods, food additives, etc.

Specifications of Powder Packing Machine

| Model | FL – 200 | FL – X00 – XL |

|---|---|---|

| Bag Length | 50–180 mm | 160 mm |

| Bag Width | 20–90 mm | 30 mm |

| Max Width of Roll Film | 200 mm | – |

| Packaging Material | OPP/CPP, OPP/PE, PET/PE | – |

| Packaging Speed | 30 cuts/row/min | 30 cuts/min |

| Measuring Range | 0–50 ml | 10–50 g/bag |

| Weighing Accuracy | – | ≤±5%, 15g ±0.8g |

| Air Pressure | 0.65 MPa | – |

| Gas Consumption | 0.1 ㎡/min | – |

| Air Tightness | – | No leakage at 60kPa, leakage rate ≤0.2% |

| Power Voltage | 220 V | – |

| Power | 2.5 KW | – |

| Dimension (L×W×H) | 1500×1300×2300 mm | – |

| Machine Weight | 220 kg | – |

Working Principle of Powder and Granule Packaging Machine

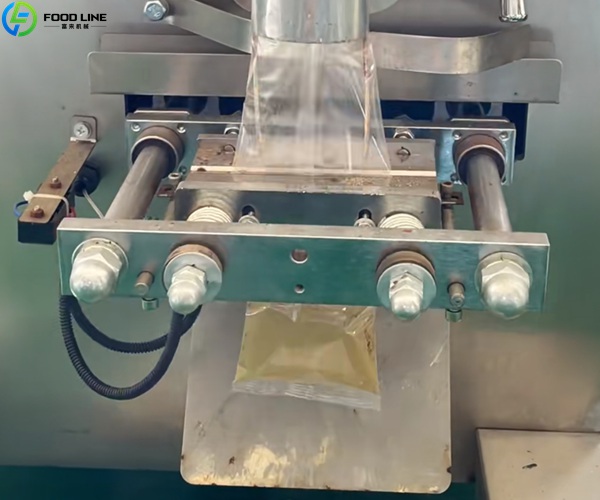

After the equipment starts, the packaging film enters the forming unit and folds into a strip-shaped bag structure. The machine then fills the product into the bag. To handle different material characteristics, the powder bagging machine uses different metering systems.

- Powder screw metering: It is mainly used for filling powdered products, such as milk powder, coffee powder, and flavoring powder.

- Granule measuring cup: Suitable for small granular products with good flowability, such as sugar granules and instant beverage granules.

- Liquid filling pump metering: Suitable for liquid or sauce products with a certain degree of fluidity.

After filling is completed, the equipment performs lateral sealing and cutting to complete the manufacturing process.

Features of Powder and Granule Packaging Machines

- Packaging Design: The equipment adopts a strip-shaped packaging structure. The finished product features a neat appearance that facilitates retail display and supports individually packaged small-dosage products.

- Dimensions: The packaging machine allows for adjustable bag length and width to meet the packaging needs of products with different specifications. Bag length ranges from 50–180mm, and bag width ranges from 20–90mm, offering strong applicability.

- Metering System: The machine configures different metering methods according to the product form. It meets the packaging needs of granular, powder, and liquid products, reducing the cost of equipment purchase for enterprises.

- Area: The overall machine has a small footprint, suitable for small and medium-sized factories or workshops with limited production space.

- Operating Parameters: The equipment’s packaging speed can reach 30 cuts/column/minute. The machine maintains stable output while ensuring sealing quality, making it suitable for continuous production needs.

Advantages of Powder Bagging Machine

- Metering Accuracy: The powder and granule packaging machine has a metering unit of 0–50ml, meeting the needs of products with different dosages and reducing material waste.

- Energy and Gas Supply: The overall design of the equipment prioritizes operational efficiency. Gas consumption is approximately 0.1 m²/min, helping to reduce overall energy costs during operation.

- Products: This powder bagging machine applies to beverage powders, sauces, seasonings, and other products. With the appropriate configuration, it packages powdered and small granular products efficiently.

- Design: The packaging machine’s exterior design facilitates later maintenance and parts replacement, reducing downtime and improving production efficiency.

FAQ

No. The equipment can package powder, granules, and some liquid products by configuring different metering devices.

The equipment is relatively easy to change, suitable for switching production between different product specifications.

By selecting a suitable metering system, the equipment can adapt to materials with varying flow rates, ensuring packaging quality.

Why Choose Foodline Machinery?

We have 20 years of experience in machinery manufacturing, specializing in the food machinery sector. Before leaving the factory, every piece of equipment undergoes rigorous debugging and testing to ensure stable operation under various conditions. We can provide customized design solutions based on our clients’ specific product requirements.

If you also produce liquid materials, please feel free to check out our liquid packaging machines. Request a quote! WhatsApp/Phone: +86 13838385752.