If you are looking for meat processing equipment that can help you get tender, delicious, and uniform meat products. Then our saline injection machine is the ideal choice for you. Designed with advanced technology and meeting the highest food hygiene standards, this equipment is the key to upgrading your production line and increasing your output. If you want to know more about this product, please contact us! WhatsApp/Phone: +86 13838385752.

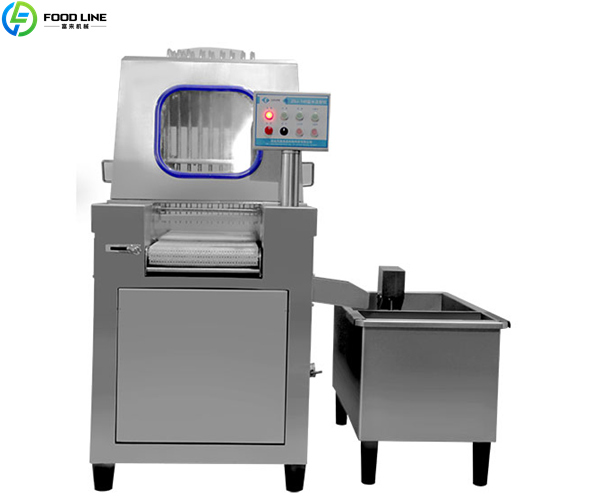

Saline Injection Equipment Overview

A brine injector is a vital tool in meat processing plants. It injects a brine solution composed of salt and seasonings directly into meat. This process shortens curing time, ensures flavor, and improves the taste of the meat.

Unlike traditional curing methods that require lengthy soaking processes, this machine is fast and precise, ensuring product quality even in large-scale production. It is widely used for ham, bacon, poultry, seafood, and other processed meat products. By incorporating this machine into your production process, you can not only improve the taste of your product but also significantly increase your yield.

Specifications of Brine Injector

| Model | FL-80 |

|---|---|

| Injection Needles | 80 pcs |

| Production Capacity | ≈800-1000 kg/h |

| Power | 4.15 kW |

| Injection Pressure | 0.2-0.7 MPa |

| Tank Width | 400 mm |

| Needle Vertical Stroke | 170 mm |

| Injection Speed | Variable Frequency |

| Chain Step Distance | 120 mm |

| Optional Needle Spec. | Ø304 mm |

| Host Machine Dimensions | ≈1350*1250*1720 mm |

| Weight | ≈500 kg |

Working Principle of the Brine Injection Machine

The brine injection machine operates on a multi-needle injection system. When meat is fed beneath the injection head, the machine pumps brine into the muscle fibers through stainless steel needles. This process is controlled by a pressure regulation system, ensuring uniform brine penetration throughout the entire piece of meat.

Features of Saline Injector

High-Quality Stainless Steel Construction

This machine is constructed entirely of SUS304 stainless steel. It offers exceptional durability, a long service life, and full compliance with food safety standards.

Automatic Protection System

Equipped with an intelligent lifting mechanism. The injection needle automatically raises when it strikes a hard object, ensuring safety and reducing downtime.

Advanced Filtration System

An integrated filter effectively removes residual meat particles, ensuring smooth brine circulation without clogging the pump or needle.

Stable Pressure Control

A dedicated pressure stabilizer ensures stable injection, ensuring even distribution of brine across all cuts of meat.

Customizable Injection Settings

Operators can adjust parameters such as step speed, step distance, pressure, and press plate gap to achieve optimal results.

Easy to Clean and Maintain

The removable conveyor chain and modular design simplify cleaning, helping processors maintain the highest hygiene standards.

High Production Capacity

The brine injection machine is equipped with 80 injection needles and has a processing capacity of 800-1000 kg per hour, making it suitable for medium and large-scale production.

Free Quote! WhatsApp/Tel: +86 13838385752.

Advantages of Brine Injection Equipment

Increased Yield

By injecting brine directly into the meat fiber, processors can achieve higher yields with the same raw material.

Improved Flavor and Mouthfeel

Evenly distributes brine, resulting in a juicier, more flavorful product.

Time-Saving and Efficient

Reduces marinating and preparation time, speeds up turnaround, and increases daily output.

Versatility

Capable of processing a variety of meats, including poultry, pork, beef, seafood, and cured products.

Cost-Efficient

Reduces labor while maintaining consistent quality, ensuring long-term cost savings.

Reliable and Durable

Utilizes robust components and safety mechanisms to ensure stable, long-lasting performance.

Applicable Products

Saline Injection Machines are widely used in:

- Ham and Bacon: Ensures even penetration of salt and seasonings for optimal curing.

- Poultry: Tenderizes chicken and turkey while enhancing juiciness.

- Seafood: Injects marinade into fish and shrimp to improve flavor and moisture.

- Processed Meat: Suitable for processing various meat products before tumbling or curing.

FAQ

Yes. Thanks to its intelligent needle lift mechanism, the machine can safely inject both boneless and bone-in products without damaging the needle.

The conveyor chain and injection components are removable. They can be easily cleaned with water and disinfectant to maintain strict hygiene standards.

This machine can process approximately 800-1000 kg of meat per hour, making it suitable for large-scale production.

No. A built-in filtration system continuously removes particles, preventing clogging of the pump or needle.

Why Choose Foodline Machinery?

When investing in a brine injection machine, you need more than just equipment; you need a reliable partner. Our company offers:

- Industry Expertise: Years of experience in manufacturing food processing equipment.

- Customized Solutions: We tailor our machines to your specific production needs.

- After-sales Support: Comprehensive training, technical support, and maintenance guidance are provided.

If you’re looking to increase efficiency, improve product quality, and stay competitive in the meat processing industry, our brine injection machines are the ideal solution. Contact us today to learn more about our brine injection machines and let them help you increase your profits! WhatsApp/Phone: +86 13838385752.

In addition, we have other meat equipment, bone sawing machine.