Packaging equipment is crucial in the modern food, condiment, and daily chemical industries. To achieve more efficient and standardized production methods, vertical packaging machines are essential equipment in various liquid, paste, and sauce production lines. They not only improve packaging efficiency but also enhance a company’s product competitiveness. Contact us! WhatsApp/Phone: +86 13838385752.

Liquid Form Fill and Seal Machine Overview

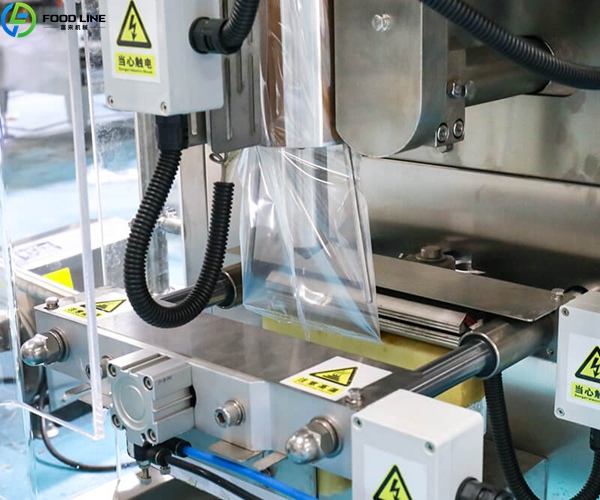

A vertical packaging machine is an automated device that uses roll film as the packaging material. It completes product packaging through an integrated process of bag making, filling, sealing, and cutting. Vertical packaging machines feature a vertical structure, occupy a small area, and have a high degree of automation. They are suitable for small and medium-sized factories and enterprises that need to improve packaging efficiency.

The equipment features a compact design and is constructed entirely of high-quality stainless steel. It meets food hygiene standards and is suitable for handling liquids and pastes such as sauces, oils, pastes, seasonings, and shampoos. Its advanced PLC centralized control system and touchscreen interface allow operators to easily adjust packaging parameters and intuitively understand the equipment’s operating status.

Specifications of Vertical Packaging Machine

| Model | FL – P150 |

|---|---|

| Applicable Materials | Sauces, liquids, pastes |

| Packaging Speed | 20-120 bags/min |

| Bag Making Width | 40-100 mm |

| Bag Making Length | 50-150 mm |

| Packaging Form | Three-side seal, Four-side seal |

| Packing Capacity | 5~100 ml |

| Power Supply | 220V/50HZ |

| Power Consumption | 5.5KW – 6.5KW |

| Air Pressure | 0.6 mpa |

| Main Machine Dimensions | 1356x811x2018 (mm) |

| Main Machine Weight | Approx. 620 kg |

| Servo Configuration | Longitudinal seal servo, Hot seal servo, Cold seal servo, Cutter servo |

| Feeding Configuration | Jubao pump, Magnetic pump, Mechanical pump, etc. |

| Coding Configuration | Inkjet coding on sealing area, Ribbon coding, Thermal transfer coding, etc. |

Vertical Packaging Equipment Applicable Products

- Liquids and sauces: soy sauce, vinegar, condiments, chili sauce, ketchup, jams and glazes.

- Daily chemical industry: shampoo, facial cleanser, laundry detergent, disinfectant.

- Flowable liquids: lubricating oil, industrial liquid raw materials.

Features of Vertical Filling Machine

Four-servo Drive Configuration

The equipment employs a four-servo motor configuration, enabling more precise bag making, film stretching, sealing, and cutting actions. Synchronous control across different stages improves the appearance precision and sealing effect of the finished bags.

PLC Centralized Control and Touchscreen Operation

The intelligent operating system makes the entire packaging process visible and data-driven. Operators can adjust parameters such as packaging length, speed, and temperature on the screen.

Fault Tracking and Detection System

The equipment can monitor its operating status in real time. If film material deviation, abnormal temperature, or malfunction occurs, the equipment will issue an alarm promptly to help users handle the situation.

Sealing Methods

Supports multiple sealing methods including three-side sealing, four-side sealing, and back sealing. Suitable for different product market positioning and packaging style requirements.

Structure

The entire equipment is constructed of food-grade stainless steel, meeting international hygiene standards and requiring simple daily maintenance.

Feeding Method

High-quality pumps, magnetic pumps, and piston pumps can be selected according to material characteristics. These feeding devices all ensure the quality of the output.

Contact Us! WhatsApp/Phone: +86 13838385752.

Advantages of Automatic Vertical Packing Machine

High Efficiency

Up to 120 packs/minute, suitable for mass production and OEM processing needs.

Quantitative Control

A metering system and stable sealing structure reduce packaging errors and improve raw material utilization.

Operation

Automated packaging processes reduce manual intervention, allowing companies to operate production lines without relying on skilled packaging workers.

Forming

The equipment uses advanced temperature control technology. Sealing is smooth and aesthetically pleasing, enhancing product appeal in the market.

Scalability

By changing the film roll size, adjusting the bag maker, or replacing the feeding system, it can accommodate different types of materials.

Maintenance Costs

The machine’s simple structure and standardized parts design result in low and convenient maintenance and replacement costs.

FAQ

This model is mainly used for packaging liquids, oils, and pastes. If you require powder packaging, we can recommend a suitable powder packaging machine model.

Yes. The packaging width ranges from 40–100mm, and the length ranges from 50–150mm, which can be adjusted according to product requirements.

The equipment is made of food-grade stainless steel with a simple structural design, facilitating daily cleaning and maintenance.

Yes. We can customize it according to your flowability, viscosity, and production volume requirements.

About Foodline Equipment

- CE certification

- After-sales service

- Export experience

If you’d like to learn more about this ointment packaging machine, please feel free to contact us! In addition, we also have powder packaging machines. WhatsApp/Phone: +86 13838385752.