Mr. Jean-Luc Moreau is the founder of a French bakery that primarily supplies handmade puff pastry products to local cafes, supermarkets, and hotels. As order volumes increased, traditional manual and semi-automatic equipment could no longer meet the demands for consistent quality and large-scale production.

After comparing several automated systems, Mr. Moreau ultimately chose to purchase an automatic puff pastry-making machine from our company to meet from our company for his production needs. He said after using it, “As a pastry chef, I was initially hesitant about purchasing equipment from overseas. However, after using it daily, this decision exceeded my expectations. This machine produces dough layers of uniform thickness and achieves excellent butter layering. Our production capacity has increased significantly, while labor costs have decreased. The machine is easy to operate and clean. Most importantly, the technical team provided detailed installation instructions and after-sales support. Even with the time difference, they were able to provide timely assistance.”

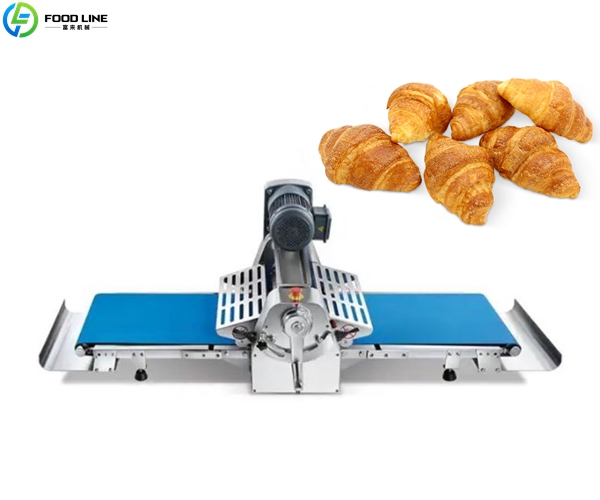

Parameters of Puff Pastry Sheeter Machine

| Model | Type | Power | Voltage | Conveyor Belt Size | Size (mm) | Weight |

|---|---|---|---|---|---|---|

| FL-400A | Stand Type | 0.75 kW | 220/380V | 400-2020mm | 2440×825×1180mm | 208 KG |

| FL-520A | Stand Type | 0.75 kW | 220/380V | 500-2020mm | 2440×955×1220mm | 258 KG |

| FL-630A | Stand Type | 0.75 kW | 220/380V | 600-2300mm | 2900×1100×124.0mm | 258 KG |

| FL-670A | Stand Type | 0.75 kW | 220/380V | 650-2400mm | 2900×1100×124.0mm | 260 KG |

| FL-520CUT | Sheeter with cutter | 0.55 kW | 220/380V | 500-2160mm | 2540×950×106.2mm | 195 KG |

Features of Puff Pastry Machine

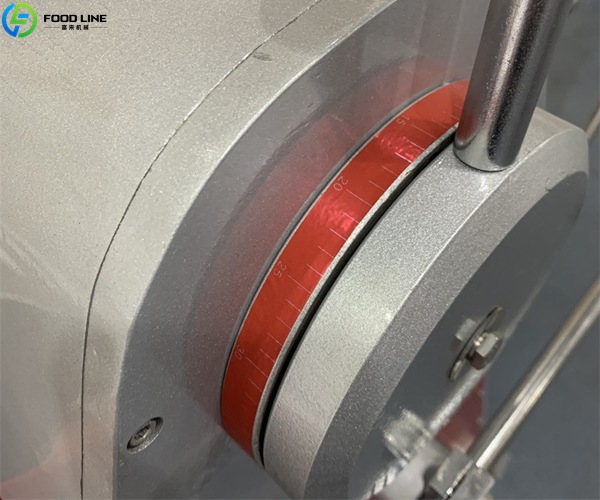

- Puff Pastry Structure Control: The equipment features a roller system and intelligent layering structure. This design ensures even distribution of dough and butter, guaranteeing consistent puff pastry thickness.

- Automation: The entire machine utilizes an intelligent control system. Multiple puff pastry parameters can be preset, including rolling thickness, folding count, and operating speed. Operators can operate the equipment after simple training.

- Materials: All parts in contact with food are made of food-grade stainless steel, ensuring equipment compliance.

- Operation: The equipment has a robust structure, and the motor and transmission system are durable. Suitable for high-intensity use in bakeries, central kitchens, and industrial baking plants.

Advantages of Automatic Puff Pastry Making Machine

- Quality: Finished products maintain a high degree of uniformity in layering and thickness, effectively reducing errors caused by human operation and improving product stability.

- Cost: One machine can replace multiple operators. Especially in France where labor costs are high, the return on investment period is shortened.

- Capacity: Automated production increases daily output.

- Image: Using automated puff pastry equipment allows for higher-quality products that better reflect the company’s image.

Why Choose Foodline Machinery?

- Export Experience: We have a long history of exporting equipment and are familiar with our clients’ requirements for process details and quality standards.

- Customization: We customize products to meet our clients’ specific product types, workshop space, and production capacity targets.

- After-sales Service: We provide comprehensive support throughout the entire process, from equipment selection and production scheduling to installation guidance.

- Cost-Effectiveness: While ensuring equipment quality and stability, our prices are highly competitive.

If you would like to learn more about puff pastry machines and pricing, please feel free to contact us! WhatsApp/Phone: +86 13838385752.