Nguyen Van Hoang, a meat processing plant owner from Vietnam, contacted us. He runs a medium-sized meat processing company that supplies beef, pork, lamb, and some seafood to local supermarkets, restaurants, and hotels. As business volume grew, the existing manual cutting equipment and outdated semi-automatic machines could no longer meet the high-intensity production demands. Low cutting efficiency, uneven thickness, and high manual labor intensity became the main issues hindering production.

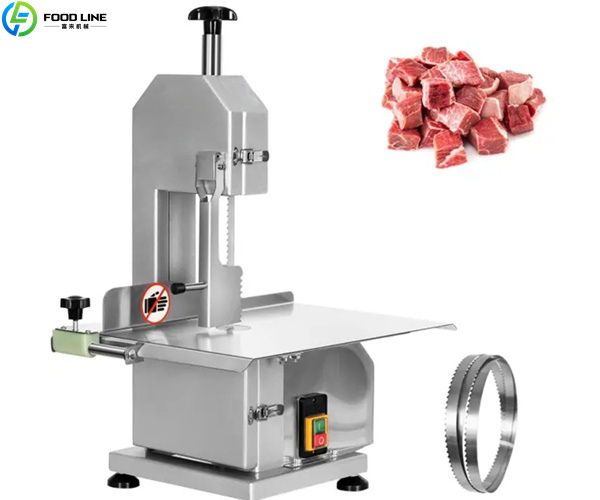

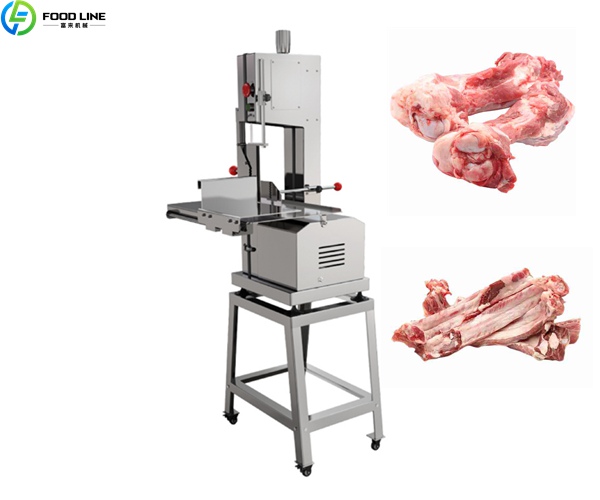

After comparing various options, Nguyen chose our Model 310 commercial bone cutting machine. Our video demonstration detailed its high-speed cutting, large table design, precise guide system, and safety features. We also provided a capacity calculation tailored to his production needs. After the equipment was installed, Nguyen provided positive feedback:

“This 310-model commercial bone cutting machine offers high stability and fast cutting speeds. It maintains consistent thickness and accuracy even during peak production. It’s easy to operate and clean, saving significant labor costs and significantly improving our production efficiency.”

Meat Cutting Band Saw Specifications

| Product Parameters | Details |

|---|---|

| Product Name | FL-B310 |

| Motor Power | 2200W (Pure Copper) |

| Rated Voltage | 220V (Customizable) |

| Cutting Speed | 300m/min |

| Saw Blade Model | 1980mm |

| Cutting Height | 0~310mm |

| Cutting Width | 5~190mm |

| Net Weight | 55kg |

| Platform Size | 610×430mm |

| Body Size | 630×530×1050mm |

Overview of the Bone Saw Machine Market in Vietnam

Meat consumption in Vietnam continues to grow, with beef, pork, and seafood occupying a prominent place on residents’ tables. With accelerating urbanization, supermarket chains, restaurant groups, and meat processing companies are increasingly demanding efficient and stable processing equipment.

In recent years, Vietnamese processing plants have generally begun to introduce more automated equipment, with commercial bone cutting machines seeing a significant increase in market share. Compared to traditional equipment, these machines effectively improve production efficiency, ensure food safety, and generate higher profit margins for businesses.

Features of Commercial Bone Cutting Machines

High Performance

The 310 model is equipped with a high-performance industrial-grade motor that delivers continuous and stable power, maintaining cutting speed even during extended operation. The high-torque design ensures smooth handling of large bones, hard bones, and frozen meat, reducing downtime for adjustments.

High-Precision Guide System

The saw blade runs smoothly, and the wear-resistant guide wheel and precision tension adjustment mechanism ensure straight, consistent cuts. Minimal tolerances ensure every cut meets customer specifications.

Easy to Clean

The equipment features a modular design, allowing for quick cleaning of the saw blade, guide plate, and table. All food-contact components are made of food-grade stainless steel, which is corrosion-resistant, easy to clean, and meets international food safety standards.

Multiple Safety Features

Equipped with an emergency stop switch, protective cover, overload protection system, and automatic power-off function, these features reduce operational risks. These safety features not only meet international certifications but also provide peace of mind for operators during demanding tasks.

Advantages of Bone Cutting Machines

- High Productivity: Compared to manual or low-power equipment, this significantly improves efficiency. This significantly alleviates production capacity pressures, especially during peak holiday order periods.

- Quality Assurance: Whether cutting fresh meat or frozen bones, the machine maintains consistent cutting thickness, eliminating customer complaints and returns due to uneven cutting.

- Reduced Labor Costs: A single Model 310 commercial bone cutting machine can replace the cutting work of multiple skilled workers, reducing labor pressure and training costs.

- Adaptable to Various Processing Needs: In addition to beef, lamb, and pork bones, it can also process large fish, frozen meat, and other hard ingredients. This machine allows businesses to expand their product offerings.

About Foodline Machinery

We are a manufacturer specializing in the research, development, and production of food processing machinery, with 20 years of experience in large-scale machinery manufacturing. The company boasts:

- International export experience: Our equipment has been exported to countries and regions including the United States, Canada, Mexico, and France.

- Strict quality management: From raw material procurement to finished product testing, the entire process complies with international food safety standards.

- A comprehensive after-sales service system: Remote technical guidance, training, and spare parts supply are provided to ensure long-term and stable operation of the equipment.

If you are also interested in this bone saw machine, please contact us. Let us be your trusted assistant! WhatsApp/Phone: +86 13838385752.