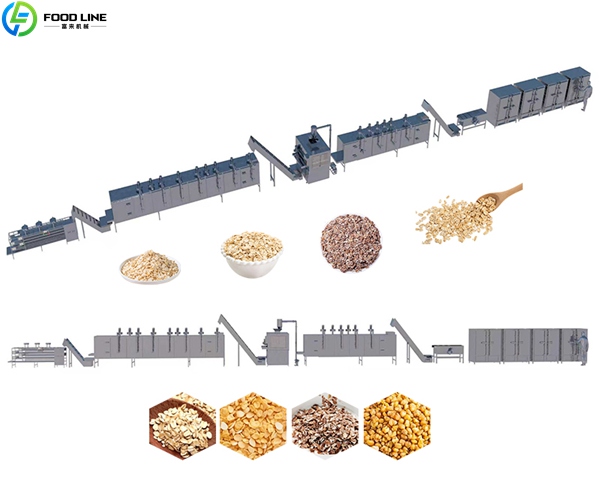

Overview of Canadian Customer Purchasing A Cereal Production Line

The client, a Canadian company owner, is a food processing enterprise specializing in the research and production of breakfast cereals, instant oatmeal, and healthy puffed snacks. Their products have long been supplied to local supermarkets and parts of the US market. With the continued growth in North American consumer demand for healthy breakfast foods, especially corn flakes, whole-grain cereals, and low-sugar breakfast cereals, the company plans to upgrade its existing production line and add a highly automated and stable cereal production line to meet the increasing order demand.

The client compared several food machinery manufacturers, focusing on the level of automation, production stability, finished product quality, energy consumption control, and after-sales service capabilities. After multiple rounds of technical communication and solution comparison, the client ultimately chose to purchase a corn flakes processing machine from our company. This production line will be used for the large-scale production of corn flakes and compound breakfast cereal products.

After using the equipment, Mr. Daniel Robertson, the purchasing manager, provided the following feedback: “We have been operating this production line for several months now, and its overall performance has exceeded our expectations. The production line runs smoothly, with stable output and high-quality corn flakes. Compared to our previous equipment, labor costs have been reduced, and production efficiency has been improved. This grain production line has become a key component of our expansion plans in Canada.”

Parameters of Cereal Production Line

| Equipment | Max Capacity / Output | Power | Weight | Dimensions (L×W×H) / Other Specs |

|---|---|---|---|---|

| Mixing Tank | 900 L | 4 kW | 180 kg | φ1150*2070 mm |

| Feed Pump | 5 m³ | 3 kW | – | Caliber: 40 mm |

| Impact Grinder | – | 11 kW | 230 kg | 990*440*1050 mm |

| Storage Tank | 900 L | 3 kW | 170 kg | φ1150*2070 mm |

| Feed Pump | 5 m³ | 3 kW | – | Caliber: 40 mm |

| Flake Drum Dryer | 10-12 ton/24h | 22 kW | 25 ton | 5200*3600*4800 mm Roller: φ2000*4000 mm Steam Pressure: 0.6-1.0 MPa Steam Consumption: 300 kg/h |

| Primary Crusher | – | 3 kW | 480 kg | 5750*540*1470 mm |

| Inclined Conveyor | – | 3 kW | 230 kg | 4020*406*500 mm |

| Flake Pelletizer | 450 kg/h | 3 kW | 120 kg | 1320*786*2010 mm |

| Cyclone Grinding Unit | 350-400 kg/h | 11 kW | – | 3500x820x2500 mm Spindle Speed: 4000 r/min Fineness: 60-80 mesh Material: 304 Stainless Steel Power Supply: 3-phase 380V 50-60Hz |

Corn Flakes Processing Machine Overview

A cereal production line is a process that includes raw material handling, mixing, puffing, flaking, drying, cooling, and subsequent packaging. It primarily produces corn flakes, breakfast cereal flakes, puffed cereals, and various other cereal products. This production line is widely applicable to food processing plants, cereal product companies, and manufacturers focusing on healthy breakfast foods. It is particularly suitable for customers with high requirements for food safety, production efficiency, and product consistency.

Features of Corn Flakes Production Line

- Automation: Operators can set parameters and monitor operation via a PLC touchscreen. This design reduces manual intervention and improves efficiency.

- Material: All parts in direct contact with materials are made of food-grade 304 stainless steel. The structural design facilitates cleaning and maintenance and meets food production standards.

- Quality: In the tableting and drying stages, the equipment uses precise temperature and pressure control to maintain a high degree of consistency in the thickness, crispness, and moisture content of the corn flakes.

- Variety: This cereal production line can also produce other puffed cereal products by changing molds and adjusting process parameters.

Advantages of Breakfast Cereal Production Line

- Capacity: The corn flakes processing machine can be customized to meet customer needs.

- Cost: Increased automation reduces reliance on manual labor. This lowers labor costs and reduces quality fluctuations.

- Maintenance: The equipment has a rational structure, easy-to-replace wear parts, and low daily maintenance costs.

- Return on Investment: This cereal production line has demonstrated high cost-effectiveness in actual customer operations, with a clear investment payback period.

Why Choose Foodline Equipment?

- Mechanical manufacturing experience

- Customized solutions

- Professional after-sales service

- Focus on long-term partnerships

Please contact us for quotes on single machines and production lines! WhatsApp/Phone: +86 13838385752.