Overview of Italian Customer Purchasing Puff Pastry Machine

The customer who purchased this puff pastry machine is a professional baking company from Italy. Mr. Marco Bianchi runs a baking factory that primarily supplies frozen puff pastry dough and semi-finished baked goods to chain coffee shops, supermarkets, and catering channels. With increasing order volume, the production model, which relied on manual labor and semi-automatic equipment, gradually revealed problems such as low efficiency, high labor costs, and inconsistent product quality.

Before the procurement, Mr. Marco clearly stated the following core requirements:

- Improve the layering stability of the dough

- Reduce reliance on workers

- Achieve continuous production

- Comply with EU food safety standards

- Integrate with existing dough mixers, dividers, and shaping machines

After comparing several suppliers, Mr. Marco ultimately chose to purchase our puff pastry machine.

Marco Bianchi said, “Before using this puff pastry machine, our old equipment was inefficient and heavily reliant on manual labor. Now the machine can reliably complete multiple folds and rolls. What pleases me most is that it has not only improved efficiency but also increased the quality of our products, which is crucial for large-scale supply.”

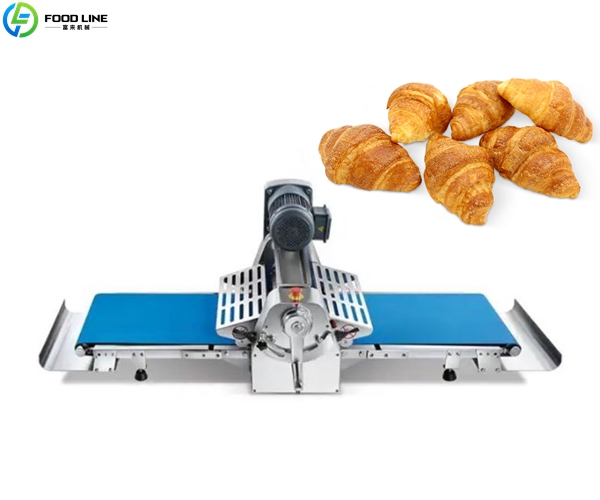

Parameters of Puff Pastry Dough Sheeter

| Model | FL-420 | FL-520 | FL-630 | TFL-420 | TFL-520 |

| Voltage(v) | 110/220/380 | 110/220/380 | 110/220/380 | 110/220/380 | 110/220/380 |

| Power(kw) | 0.75 | 0.75 | 0.75 | 0.4 | 0.75 |

| Conveyor(mm) | 400*1700 | 500*2000 | 610*2800 | 400*1700 | 500*2000 |

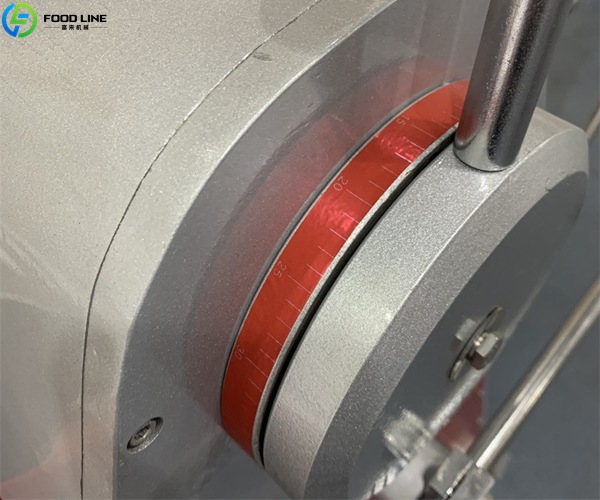

| Nip Roller Spacing(mm) | 1-50 | 1-50 | 1-50 | 1-50 | 1-50 |

| Rolling Amount(kg) | 4 | 5 | 6.5 | 4 | 5 |

| Dimensions(mm) | 855*2020*1285 | 955*2020*1285 | 1055*3320*1285 | 1900*800*700 | 2430*880*1230 |

| Weight(kg) | 260 | 300 | 350 | 110 | 240 |

Features of Puff Pastry Machine

- Conveying System: The equipment is equipped with a reversible conveyor belt system. Operators can perform multiple rolls and folds according to the product formula, resulting in more uniform dough layers.

- Thickness Adjustment: The puff pastry machine uses an adjustable mechanism to adjust the dough thickness. This ensures product quality and reduces quality fluctuations caused by human error.

- Material: All parts of the machine that come into contact with food are made of food-grade stainless steel. This facilitates daily cleaning and maintenance, meeting customer requirements for hygiene and compliance.

- Operation: Through the control system, operators only need basic training to become proficient, reducing reliance on manual labor.

Advantages of Industrial Puff Pastry Machine

- Cost: A single puff pastry sheeter can complete the rolling and folding processes that previously required multiple workers, reducing labor input.

- Quality: Standardized operating parameters ensure high-quality dough, effectively reducing the proportion of defective products.

- Efficiency: The puff pastry sheeter can be connected to various baking equipment to create a continuous production process, enabling factories to maintain delivery during peak order periods.

- Product Requirements: Whether it’s bread dough or cookie dough, this puff pastry dough sheeter can handle the demands by adjusting the parameters.

Why Choose Foodline Equipment?

- Customized solutions

- Export experience

- R&D team

- CE certification

- After-sales service

Feel free to contact us for a quote! WhatsApp/Phone: +86 13838385752.