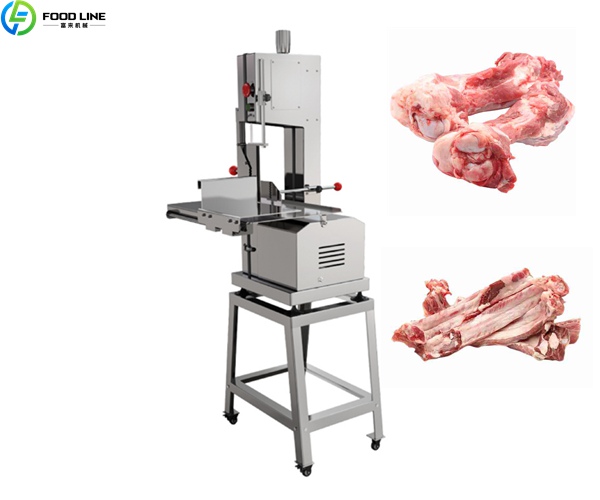

Carlos Eduardo Silva, a restaurateur from São Paulo, Brazil, contacted us. He runs a mid- to high-end restaurant specializing in steak and lamb. In recent years, the restaurant’s meat processing needs have continued to grow, and the kitchen’s cutting workload has become increasingly demanding. He urgently needed an efficient, stable, and compact bone saw to improve his productivity.

Carlos compared several domestic and international suppliers, carefully researching the performance and pricing of each brand. Ultimately, he chose our Model 250 table bone saw machine. We arranged an online video demonstration for him, detailing the machine’s cutting speed, safety features, and ease of cleaning. He also referenced our existing customer references in South America. This gave him confidence in the product’s durability and reliability. After using the equipment, Carlos provided the following feedback:

“This 250 model cuts precisely and very quickly. It’s also easy to clean. It reduces the chef’s workload, and the consistency of meat production has significantly improved. The shipping and installation process was smooth. The after-sales team is responsive and provides excellent service. I’m very satisfied with this purchase.”

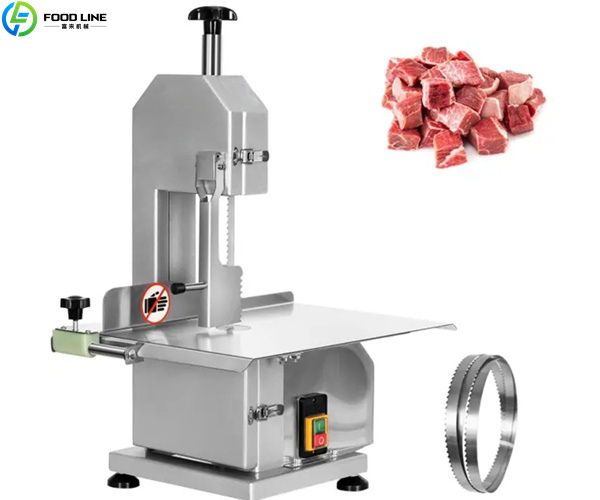

Parameters of the Bone Saw Machine

| Parameter | Specification |

|---|---|

| Product Name | FL-250 |

| Cutting Height | 0–250mm |

| Motor Power | 1500W (Pure Copper) |

| Cutting Width | 5–165mm |

| Rated Voltage | 220V (Customizable) |

| Machine Weight | 46kg |

| Cutting Speed | 300m/min |

| Platform Size | 530×360mm |

| Blade Model | 1650mm |

| Machine Dimensions | 530×490×880mm |

Table Bone Saw Machine Features

- Compact Tabletop Design: The 250 model features a tabletop design, offering a compact footprint and flexible layout. It’s ideal for restaurants, butcher shops, and small to medium-sized processing plants with limited kitchen space. No complex installation required; simply place firmly on the workbench and you’re ready to go.

- Powerful Power System: Equipped with a high-performance motor, it delivers stable power. It cuts large beef, lamb, and pork bones, as well as some frozen meats, smoothly and without stuttering.

- High-precision Guiding and Cutting System: Using wear-resistant guide wheels and a high-toughness saw blade, the saw cuts straight and uniformly.

- Multiple Safety Features: Equipped with a protective cover, emergency stop button, and safety switch, it effectively prevents accidental injuries during operation and meets the safety certification requirements of multiple countries.

- Multiple Models Available: In addition to the 250 model, we also offer 210, 280, and 310 models to meet diverse needs.

Bone Sawing Machine Advantages

- Significantly Improved Cutting Efficiency: Compared to manual sawing, this saw can increase work efficiency several times over, enabling rapid order preparation during peak periods.

- Improved Cutting Accuracy and Quality: Stable cutting paths, clean cuts, and consistent thickness contribute to standardized restaurant product quality and increased customer satisfaction.

- Reduced Labor Intensity: Operation requires only a gentle push of the raw material, reducing physical exertion and fatigue caused by repetitive work.

- Easy to Train and Operate: The control panel is simple and the button layout is clear, allowing new employees to quickly master its operation.

- Low Maintenance Costs: Durable and wear-resistant components offer long replacement cycles. Daily maintenance is simple, requiring only regular cleaning and checking the blade tension.

Overview of the Bone Saw Machine Market in Brazil

Brazil is a major global meat producer and consumer, ranking among the world’s top producers and consumers of beef and chicken. With the expansion of the restaurant industry and supermarket chains, demand for efficient and safe meat processing equipment continues to rise. In Brazil, particularly in major cities like São Paulo and Rio de Janeiro, restaurants and meat processing plants are showing widespread interest in tabletop bone saws, particularly those capable of efficient cutting in limited kitchen space while reducing manual labor.

Furthermore, countertop meat band saws are gaining increasing market acceptance in Brazil. Mechanized processing not only improves efficiency but also enhances food safety.

About Foodline Machinery

We specialize in the research, development, and manufacturing of food processing equipment. Our product line covers a wide range of models, including bone saws, meat grinders, and slicers. We boast:

- Extensive international export experience: Our products are sold to numerous countries and regions, including South America, North America, Europe, and Southeast Asia.

- Strict Quality Management System: From raw material selection to finished product testing, we ensure that each machine meets food safety standards.

- A wide range of models: Including 210, 250, 280, and 310 sizes to meet the needs of customers of varying sizes.

- Comprehensive after-sales service: Remote technical support, spare parts supply, and regular maintenance recommendations are provided.

We will continue to be committed to providing high-quality table bone saw machines and other food processing equipment to customers around the world, helping more companies achieve both production efficiency and food safety improvements. Welcome to consult! WhatsApp/Phone: +86 13838385752.