Customer Purchase Overview

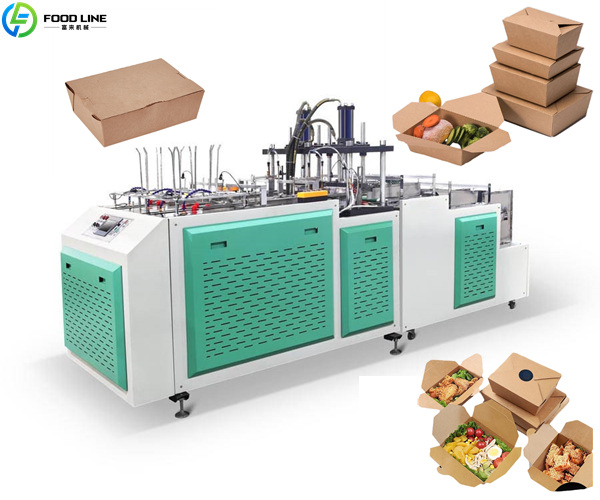

In Canada, David Kim runs a sushi restaurant. As takeout orders grew, David faced packaging challenges. Purchased takeout containers were either the wrong size or too flimsy. After comparing suppliers, he chose our takeaway pack making machine.

After implementing the takeaway pack making machine, “The first trial run of lunch boxes perfectly met our needs—they fit salmon sushi snugly, and closing the lid didn’t crush the ingredients at all,” David remarked. “Previously, I spent an hour daily checking packaging inventory. Now I can adjust production anytime based on order volume, eliminating stockout anxiety.”

David gave this takeaway pack making machine high praise: “This machine not only solved our packaging fit issues but also keeps our sushi looking its best during transport. We no longer need to repeatedly discuss details with suppliers. Now, even if we get a last-minute large team-building order, we can quickly produce enough packaging without any panic.”

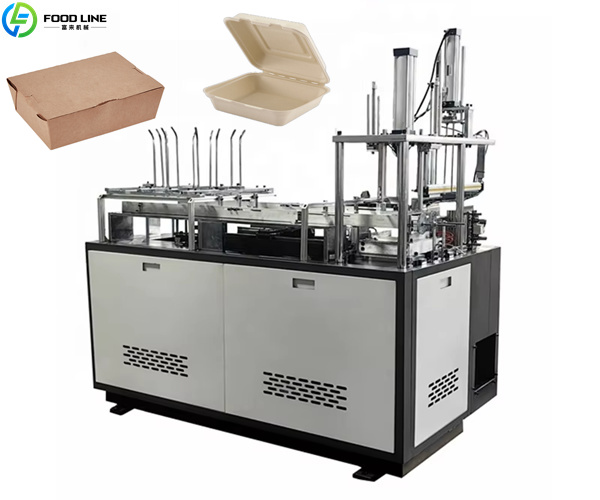

Parameters of Take Away Pack Making Machine

| Specification | Details |

|---|---|

| Model | FL-400 |

| Production Capacity | 35~45 pcs/min |

| Maximum Paper Size | 480x480mm |

| Suitable Material | 200~400g/m² PE coated paper, etc. |

| Total Power | 5kw |

| Voltage Requirement | 220V 50HZ |

| Total Weight | 350kg |

Free Quote! WhatsApp/Tel: +86 13838385752.

Workflow of Lunch Box Forming Machine

- Paper Feeding: The feeding mechanism precisely conveys raw materials such as PE-coated paper to each processing station.

- Heating: The equipment’s heating system uniformly warms the paper to the optimal forming temperature.

- Press Forming: Pneumatic and mechanical systems work in tandem to complete forming processes including film pressing, edge folding, and bottom sealing of the lunch box.

- Automatic Collection: Finished meal boxes are automatically sorted and collected by the receiving mechanism, completing the entire production cycle.

Features of Food Box Forming Machine

Multi-Specification Packaging

This takeaway pack making machine allows customization of packaging dimensions and shapes to meet the specific requirements of different food and beverage categories.

Intelligent Design

The food service industry commonly faces labor shortages and high labor costs, with complex equipment operation further increasing operational burdens. This takeaway pack making machine features a fully automated design that simplifies the operation process. Employees only need to neatly place paper into the feed inlet, and the machine automatically completes core processes such as pressing, forming, and cutting.

Pneumatic and Mechanical Fusion

The integration of pneumatic and mechanical systems delivers multiple advantages including high speed, high efficiency, stability, and environmental friendliness. The pneumatic system provides flexible drive capabilities, while the mechanical structure ensures precision and stability. Working in tandem, they jointly guarantee a more reliable meal tray forming process.

Advantages of Lunch Box Forming Equipment

Reducing Packaging Costs

In-house production replaces external procurement, lowering packaging costs. Raw material procurement costs are lower than purchasing finished packaging directly, and higher-value-for-money cardboard can be selected. In-house production avoids additional expenses associated with external procurement, such as cross-border transportation fees, supplier markups, and inventory waste from overstocking.

Operational Efficiency

The in-house production model frees businesses from reliance on external suppliers, eliminating concerns over delivery delays and packaging mismatches. This allows greater focus on food quality and service. Customized packaging better suits dish characteristics, reducing takeout complaints due to packaging issues and boosting customer satisfaction and repurchase rates.

Brand Image

Custom packaging not only complements the food but also becomes a brand representative. This rice box forming machine helps merchants strengthen brand recognition.

Foodline Equipment – Your Trust Partner

David ultimately chose our takeaway pack making machine not only for the product’s inherent advantages but also for the service guarantees we provide to customers—this is the core competitiveness of our brand.

- Professional R&D Team

- CE Certification

- After-Sales Service

- Export Experience

Choosing us means choosing a trusted partner. Contact us for a quote! WhatsApp/Phone: +86 13838385752.