Luca Moretti, an Italian entrepreneur, is the operations manager for a medium-sized sauce production company. With the brand’s rapid expansion across Europe, his company decided to upgrade its existing production line equipment to increase capacity and ensure filling accuracy. After comparing local and international suppliers, Luca ultimately selected our servo filling machine for filling tomato sauce and cream sauces.

After our initial communication, Luca expressed satisfaction with our service and professionalism. He said, “We’ve tested many brands of filling equipment, but your filling machine performs exceptionally well in terms of filling speed and accuracy, and the system control is also flexible. It’s exactly what our factory needs.”

After the equipment was delivered, Luca‘s team completed installation and commissioning under our remote guidance. Within two weeks of its official start-up, they reported, “This equipment runs smoothly, is easy to clean, and reduces manual intervention. We are very satisfied with this purchase.”

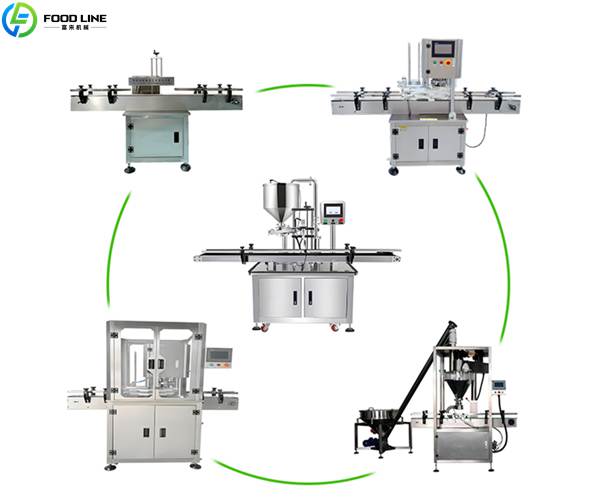

Parameter of Filling Machine

| Specification | Details |

|---|---|

| Filling range | 50–5000ML (customized according to customer requirements) |

| Number of filling heads | 2, 4, 6, 8, 10, 12 |

| Filling speed | 10–35 (Bottle/min) (Take 8 heads of 500ml as an example) |

| Working pressure | 0.6–0.8MPA |

| Bin volume | About 20lb (Take 8 heads as an example) |

| Machine size | About 42847*52180 (length-width-height) |

| Machine weight | About 600KG |

| Measurement accuracy | ±1% (Depending on the specific material) |

| Power/voltage | 2KW/220V |

Overview of the Italian Filling Machine Market

In recent years, Italy’s food industry has continued to expand, particularly in the natural and organic product sectors. To meet diverse packaging needs and stringent food safety standards, a growing number of small and medium-sized enterprises are turning to automated and intelligent packaging solutions. This has also driven demand for filling machines.

While Italy has some local filling machine manufacturers, their prices are generally high and after-sales service is limited, prompting some companies to turn their attention to smart packaging equipment manufactured in China. High cost-performance, mature technology, and comprehensive remote after-sales service are key factors contributing to the widespread acceptance of Chinese filling equipment.

Advantages of Servo Filling Machine

As a high-precision filling machine, this filling machine has the following significant advantages, which are the key factors for Luca to choose it:

- High-precision servo control system: Each filling action is independently controlled by a servo motor, with an error control within ±1%, improving product consistency and quality.

- High degree of automation: Supports automatic filling of various bottle types and materials of varying viscosities. Operators simply set parameters on the touch screen to complete the entire filling process.

- Reduced labor costs: Due to the system’s high degree of automation, only a few people are required to operate the entire machine, making it particularly suitable for automation upgrades for small and medium-sized enterprises.

- Food-grade safety standards: All parts that come into contact with materials are made of stainless steel, meeting international standards, ensuring product safety and contamination-free.

- Stable and reliable, with low failure rates: Core components are from internationally renowned brands, ensuring continuous and stable operation and reducing downtime for maintenance.

Features of Filling Machine

- Modular design facilitates future expansion and maintenance.

- Anti-drip filling head ensures a clean, neat bottle finish, enhancing packaging aesthetics.

- Intelligent sensor system automatically identifies container position and prevents filling if a bottle is missing, minimizing material waste.

Why Customers Choose Our Company

Luca’s decision to purchase our servo filling machine was based on several factors, in addition to the advantages of the product itself:

- Professional Overseas Service Experience: We have extensive export experience to the European market and understand the high standards of Italian customers for compliance, safety, and quality. We can provide CE certification, technical documentation, and remote installation guidance.

- Customized Solutions: After understanding Luca’s requirements for filling speed and bottle compatibility, we selected the appropriate model to ensure product compatibility.

- Reputation and Case Studies: We have numerous bottling project examples for clients to reference. Our work has received high praise from partners in the United States, Germany, and France, which has reinforced Luca‘s trust.

Through this successful collaboration with Italian customer Luca Moretti, our servo filling machine has once again proven its competitiveness. It not only meets the customer’s filling needs but also significantly improves production efficiency through intelligent design. In the future, we will provide more high-quality filling machine solutions to help customers achieve production automation upgrades. Welcome to contact us for more cases and technical support.