Russian Customers Purchase A Donut Production Line

A Russian food company introduced a donut production line this year. The company primarily manufactures donuts and instant coffee. After three months of supplier comparisons, they ultimately selected our company’s donut production line. To date, the production line has been operating stably, with daily output increasing by 40% and product pass rate rising from 89% to 97%.

General Manager Anna commented: “We previously relied on semi-manual processes, where production capacity and consistency were persistent pain points. After adopting your donut production line, the entire process—from dough mixing to frying and cooling—became fully controllable, significantly reducing batch-to-batch variations. The equipment’s intuitive interface allowed staff to operate independently within a week of training. More importantly, your after-sales service responds swiftly. Whenever we encounter recipe adjustments or maintenance issues, your technical team consistently provides solutions within 24 hours. Now we not only maintain stable supply to existing stores but also have the capacity to fulfill large-scale event orders.”

Parameters of Donut Processing Line

| Equipment | Size (mm) | Real Power | Motor Power | Installed Power | Output / Capacity |

|---|---|---|---|---|---|

| Mixer | 1310x800x1200 | 5 kW | 7.5 kW | 7.5 kW | 70 kg/batch (2-3 minutes) |

| Screw Conveyor | 2500x800x2300 | 1 kW | 1.1 kW | 1.1 kW | Suit for extruder |

| Electric Extruder | 2600x870x1950 | 60 kW | 75 kW | 90 kW | 300-500 kg/h |

| Holster | 2860x750x2300 | 0.2 kW | 0.37 kW | 0.37 kW | Suit for the line |

| Oven | 8400x1300x2100 | 50 kW | 1.5 kW | 66 kW | Suit for the line |

| Holster | 1800x700x1460 | 0.2 kW | 0.37 kW | 0.37 kW | Suit for the line |

| Double Roller | 3800x800x2000 | 1.2 kW | 0.75 kW | 1.5 kW | Suit for the line |

| Oil Sprayer | 930x630x760 | 0.3 kW | 0.37 kW | 0.37 kW | Suit for the line |

| Cooling Machine | 5000x700x1100 | 1 kW | 0.8 kW + 0.75 kW | 1.55 kW | 100-500 kg/h |

| Ten Head Weighing Packing Machine | 3500x2000x3700 | – | – | – | Packing Speed: 30-60 bags/min Bag Size (LxW): 50-300mm x 50-200mm Bag Making Mode: Pillow-type, Standing, Punch Max Bag Width: 400mm Film Thickness: 0.04-0.08mm |

Contact Us! WhatsApp/Phone: +86 13838385752.

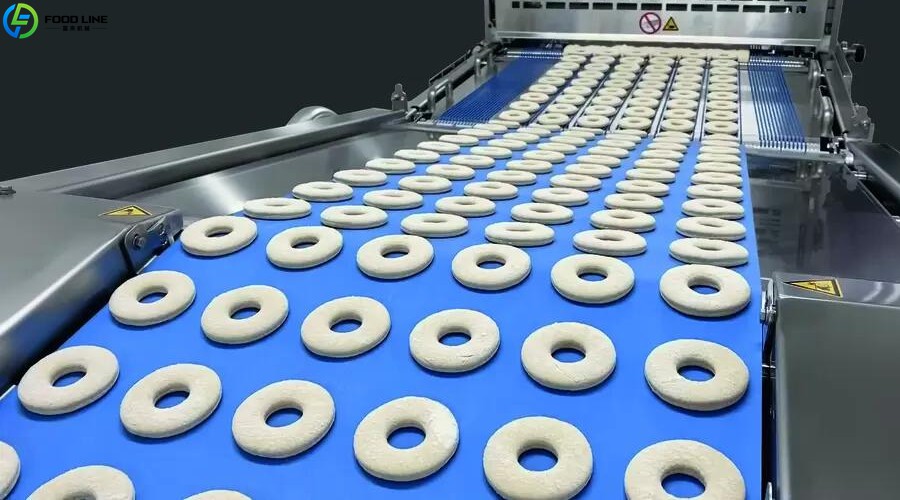

Automatic Donut Production Line Overview

Our donut production line is a scalable automated system covering the entire donut manufacturing process: from ingredient mixing, dough preparation, shaping, baking, cooling, to packaging. Constructed with food-grade stainless steel, it complies with international hygiene standards. Production capacity modules can be customized to meet specific client requirements. The equipment supports rapid switching between various donut types and accommodates adjustments for different recipes and sizes.

Features of Donut Making Machines

- Design: Each process module can be independently upgraded or expanded, facilitating gradual capacity scaling as business grows and reducing initial investment pressure.

- Control: Digital regulation of parameters (temperature, humidity, time, pressure, oil volume) with recipe storage and one-touch recall to minimize human error.

- Hygiene: Constructed with food-grade materials, featuring easy-to-clean structures and automatic cleaning functions. Equipped with safety guards and emergency shutdown devices.

- Energy Efficiency: Optimized heating and transmission systems reduce energy consumption. Grease extraction and waste oil recovery systems minimize environmental impact while meeting eco-friendly standards.

Advantages of Donut Production Line Machines

- Efficiency: Automated processes reduce manual intervention, increasing output per unit time.

- Quality: Standardized production minimizes batch variations, enhancing consistency in taste and appearance.

- Cost: Reduced labor requirements, energy consumption, and raw material waste improve profit margins.

- Adaptability: Compatible with diverse recipes and product types, supporting varied customer requirements.

About Foodline Equipment

- CE Certification

- After-Sales Service

- Professional Experience

For more information, feel free to reach out! WhatsApp/Phone: +86 13838385752.