Chicken is one of the most consumed meats globally. A professional chicken processing line is crucial for ensuring product hygiene. A chicken production line covers the entire process, from receiving live poultry, slaughtering, scalding, defecation, eviscerating, cooling to cutting and packaging.

The chicken processing production lines help businesses reduce labor costs and improve production standardization. We custom-design them based on the client’s production scale and site requirements, ensuring the entire production line better suits actual operational needs. Contact us for more information! WhatsApp/Phone: +86 13838385752.

Parameters of Chicken Processing Line

| Equipment Name | Power (kW) | Capacity / Key Parameter | Dimensions L×W×H (mm) | Other Specifications |

|---|---|---|---|---|

| Type Installation-Free Poultry Slaughtering Line | 63.5 | 500–800 pcs/hour | 11500 × 2300 × 2300 | Processing object: Broilers 2.0–2.5kg |

| Frame Vertical Poultry Coarse Hair Removal Machine | 8.8 | 2000–8000 pcs/hour | 3350 × 2300 × 2500 | – |

| A-Frame Vertical Poultry Precision Hair Removal Machine | 13.2 | 2000–8000 pcs/hour | 3350 × 2300 × 2500 | – |

| Poultry Scalding Machine | 5.2–90 | 1000–8000 pcs/hour | L × 900 × 2200 | – |

| Large Capacity Spiral Cooling Machine | 18 | Cooling Time: 35-45 min (adjustable) | L × 2700 × 2800 | – |

| Spiral Pre-Cooling Machine | 8-14 | Pre-cooling Time: 20-45 min (adjustable) | L × 2200 × 2000 | – |

| Four Power Horizontal Feather Removal Machine | 12 | 1000-2500 pcs/hour | 4200 × 1700 × 1200 | – |

| Poultry Wax Dipping Pool | – | Wax Temperature: 67-73°C | L × 1100 × 1050 | Steam Heating |

| Horizontal Speed Regulating Head And Neck Feather Removal Machine | 1.5 | Spindle Speed Adjustable | 2500 × 900 × 1600 | – |

| Fluff Feather Machine | 4.4 | – | 4000 × 950 × 2000 | For pre-scalding; Steam Heating |

| Belt Type Poultry Cage Conveyor | 1.5 | 1200 pcs cages/hour (adjustable) | L × 800 × 700 | For standard geometric cages; PVC belt |

| Climbing Lifting Belt | 0.75 – 2.2 | – | Depending on field customization | For product lifting; Food-grade oil resistant belt |

Chicken Processing Equipment Production Line Production Process

- Receiving and Quarantine: Live poultry undergo visual and sanitary inspections to ensure safe origin and compliance with slaughter requirements.

- Waiting for Slaughter: Poultry is placed in a designated area to reduce transport stress.

- Unloading and Hanging: Belt conveyors or manual assistance transport poultry in an orderly manner and hang it on hooks.

- Stunning: An electric stun machine stuns the poultry to ensure a safe slaughtering process.

- Slaughtering and Bleeding: Bleeding is performed to ensure clean and hygienic meat.

- Scalding: Poultry immerses in constant-temperature water to soften feather roots, preparing for feather removal.

- Feather Removal: Feathers are removed using coarse and fine feather removal machines.

- Evisceration: Operators remove the internal organs according to standard procedures and inspect their quality.

- Cooling: A pre-cooling machine is used for deacidification and detoxification to ensure tender meat.

- Segmentation and Further Processing: We perform subsequent processes such as segmentation, shaping, and packaging of the carcass.

Contact Us! WhatsApp/Phone: +86 13838385752.

Core Equipment of Chicken Processing Production Line

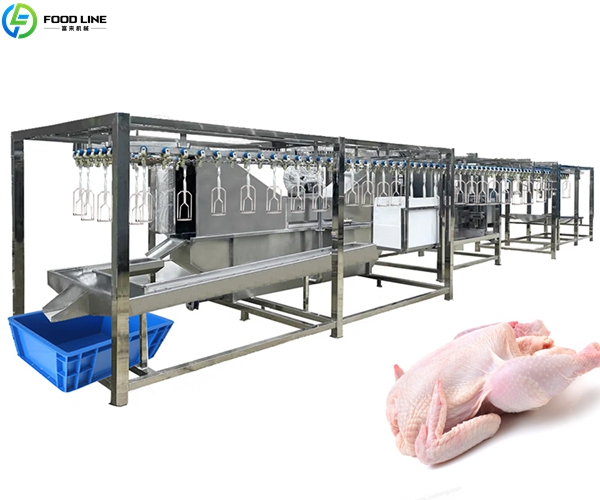

Container Type Installation Free Poultry Slaughtering Line

- The entire machine uses stainless steel construction, meeting high hygiene standards and exhibiting strong corrosion resistance.

- The “no-installation” structure significantly reduces installation costs and time.

- It offers a complete range of functions, from hanging poultry, slaughtering, scalding, and defecation to pre-cooling.

- It has a small footprint, making it suitable for work environments with limited space.

Vertical Chicken Coarse Hair Removal Machine

- Made entirely of stainless steel, sturdy and durable.

- The A-frame support is stable, and the defecation box has an opening for easy maintenance.

- The angle of the defecation box is freely adjustable to accommodate different poultry sizes.

- The automatic centering function ensures optimal defecation.

Poultry Scalding Machine

- Made entirely of stainless steel with a food-grade hygienic design.

- Features a closed chamber structure to minimize steam loss.

- Equipped with heat exchange heating to prevent scalding of poultry skin.

- Pneumatic agitation ensures even water temperature and thorough scalding.

- Modular assembly structure allows for customization to meet different customer production capacities.

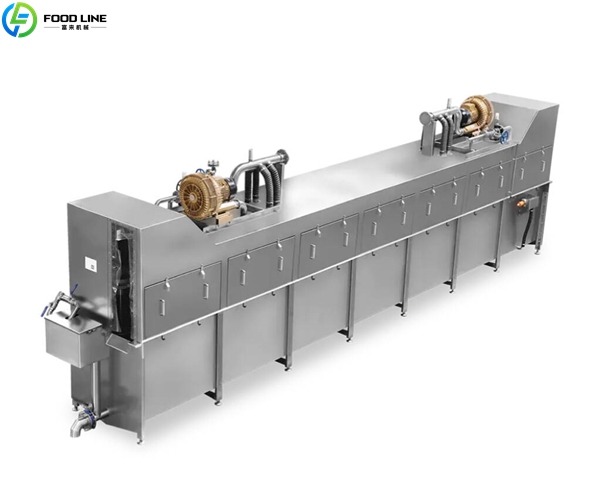

Large-capacity Spiral Precooler

- The spiral propulsion system ensures more even and thorough cooling of poultry.

- The blower system enhances cooling efficiency.

- Pre-cooling time can be adjusted according to customer requirements.

Poultry Wax Dipping Tank

- Steam heating ensures uniform temperature rise.

- A layered insulation design promotes energy efficiency.

- Separation of the wax melting and impregnation zones improves process control.

Belt-type Poultry Cage Conveyor

- Full stainless steel body, highly durable.

- Uses non-toxic and environmentally friendly PVC conveyor belt.

- Smooth operation, reliable performance, and easy maintenance.

Electric Stunner Machine

- Specifically designed for converting poultry from dynamic to static states, facilitating subsequent work.

- Stable performance.

- Safe and practical, reducing operator risks.

Features of Chicken Production Line

- Automation: The equipment utilizes an advanced PLC control system and sensor technology, requiring virtually no manual operation in all production stages (such as slaughtering, defecation, and cutting). Automation also ensures consistent and high-standard product quality.

- Professional Production Process: Every step of the chicken production line is meticulously planned, with standardized processes. The rational process design avoids duplication and cross-contamination between processes.

- Customization: Customized design services are provided based on the client’s site, production needs, and budget.

- Structure: We make all components from high-quality stainless steel, ensuring strong corrosion resistance and oxidation resistance. High-quality raw materials ensure stable operation of the equipment throughout the entire production process.

- Energy Consumption: The poultry scalding machine adopts a closed-box structure. Steam loss is minimized, and heat exchange heating reduces energy waste.

Advantages of Chicken Processing Equipment

- Efficiency: Automated equipment enables stable, high-volume production.

- Quality: Standardized operations ensure consistent appearance and taste of chicken.

- Safety: The entire production line uses food-grade materials.

- Cost Reduction: The equipment handles a large amount of repetitive labor, reducing manpower requirements.

- Scalability: Cutting lines, packaging lines, etc., can be added as needed to support business growth.

FAQ

Yes. We provide small slaughter lines with a capacity of 500–800 animals per hour and large slaughter lines that we can customize.

All equipment is made of stainless steel and meets food processing hygiene requirements.

Yes. We offer paid factory layout planning and equipment arrangement diagrams.

Why Choose Foodline Equipment?

- 20 Years of Industry Experience: Deeply rooted in the machinery and equipment field.

- Customized Solutions: Providing different specifications according to customer requirements.

- Export Experience: Extensive experience exporting equipment to multiple countries.

- After-Sales Support: A technical team provides rapid remote or on-site service.

In addition, we also offer hamburger patty forming equipment. For more information and pricing on poultry processing production lines, please feel free to contact us! WhatsApp/Phone: +86 13838385752.