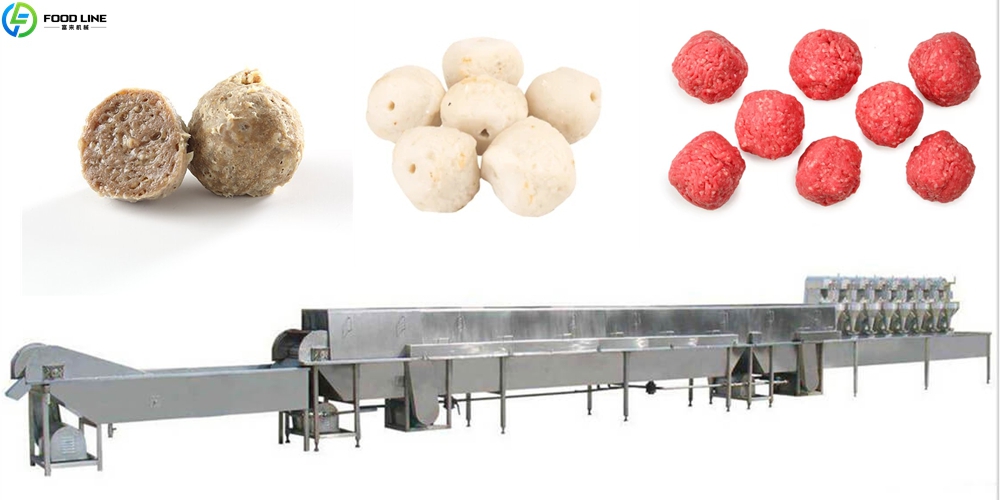

Meatballs have become an important product category for many food factories due to their tender texture, rich nutrition, and stable market demand. Meatball processing companies tend to adopt automated meatball production lines to improve efficiency.

A typical meatball production line consists of five main parts: raw material processing, forming, heat processing, cooling, and packaging. All devices on the production line work in close coordination, enabling continuous operation from meat processing to finished product packaging. To meet the needs of businesses of different sizes, the system allows you to tailor the configuration based on production requirements, site layout, or product specifications.Feel free to inquire! WhatsApp/Phone: +86 13838385752.

Specifications of Meatball Making Machines

Frozen Meat Grinder

| Model | 100 |

|---|---|

| Capacity | 300-400 kg/h |

| Motor Power | 5.5 kW |

| Plate Sizes | 5, 6, 8, 10, 12 mm |

| Feeding Inlet Size | 340 × 270 mm |

| Weight | 420 kg |

| Dimensions | 920 × 575 × 950 mm |

Pulping Machine

| Model | 150 |

|---|---|

| Power | 7.5 kW |

| Inner Diameter of Barrel | 550 mm |

| Outer Diameter of Barrel | 600 mm |

| Barrel Depth | 600 mm |

| Dimensions | 1500 × 750 × 1700 mm |

Meatball Machine

| Type | Solid |

|---|---|

| Output | 260 pcs/min |

| Power | 0.75 kW |

| Power Supply | 220/380 V |

| Mould Sizes | 18, 22, 26 mm |

| Weight | 70 kg |

| Dimensions | 400 × 700 × 1530 mm |

Shaping Line

| Model | 400 |

|---|---|

| Voltage | 380 V |

| Power | 72 kW |

| Dimensions | 4000 × 1450 × 1350 m |

Mesh Belt Conveyor

| Type | Mesh Belt Conveyor |

|---|---|

| Voltage | 380 V |

| Power | 5.25 kW |

| Mesh Belt Width | 800 mm |

| Dimensions | 4000 × 1630 × 1210 mm |

Vacuum Sealing Machine

| Model | 500 |

|---|---|

| Power Supply | 220V/380V |

| Avg. Power Consumption | 2.4 kW |

| Vacuum Chamber Size | 690 × 620 × 105 mm |

| Effective Sealing Size | 600 × 10/2 mm |

| Pumping Speed | 60 m³/h |

Meatball Production Line Workflow

The meatball production process includes: meat grinder → meat grinder → meatball forming machine → shaping line → cooking line → cooling line → packaging machine.

- Mincing: The raw meat is chopped into a uniform paste.

- Emulsification: A high-speed blade emulsifies the minced meat.

- Forming: The meatball forming machine automatically extrudes the meat paste into spherical shapes and ensures the meatballs remain uniform in size and round in appearance.

- Shaping: Hot water quickly coagulates the surface proteins of the meatballs, locks in their shape, and prevents them from falling apart or deforming during subsequent steaming or cooking.

- Steaming: The meatballs are heated with steam or hot water to ensure they are fully cooked inside.

- Cooling: The steamed meatballs reach a high temperature, so the cooling line rapidly lowers their temperature.

- Packaging: The meatballs are weighed, sealed, and packaged using a vacuum packaging machine.

Features of Meatball Making Equipment

- Automation: The entire meatball production line achieves a high level of automation, with each piece of equipment tightly integrated to support continuous operation. Automation reduces manual labor, lowers labor intensity, and maintains a high standard of hygiene.

- Quality: Parameters are controllable throughout the entire process, from mincing, emulsifying, shaping to setting and cooking. This ensures meatball quality and enhances market competitiveness.

- Modular Design: Users can choose equipment configurations based on factory size and capacity requirements. The production line can be upgraded or expanded, making production more flexible.

- Hygiene: All food-contact parts are made of 304 or 316 stainless steel. Easy to clean, corrosion-resistant, and meeting food processing hygiene standards. The closed processing flow also reduces the risk of contamination.

- Operation: The equipment has a user-friendly interface with intuitive and clear parameter settings. Durable components and low maintenance costs make it suitable for long-term continuous production.

Advantages of Meatball Processing Line

- Efficiency: Automated processes from raw materials to packaging reduce human intervention, increasing production speed and ensuring a continuous and stable supply.

- Taste: The production line includes emulsification in the pulping machine, temperature control in the cooking line, and rapid cooling processes. This results in meatballs that are elastic, have a delicate texture, and are round and aesthetically pleasing in shape, with consistent quality.

- Cost: Reduced labor costs and raw material waste. Standardized processes reduce the production of defective products, leading to lower overall production costs.

- Competitiveness: Standardized production processes make products more compliant with market demands, helping to enhance brand reputation. It is also suitable for various meatball products, such as beef meatballs, fish balls, and chicken meatballs.

FAQ

Yes. Meatball production lines support customization for small to large production volumes, and manufacturers match equipment according to the production scale.

The entire line is made of food-grade stainless steel. The smooth, corrosion-resistant surface and detachable structure make cleaning and maintenance very convenient.

Yes. By adjusting the formula, temperature, and molding parameters, it can produce various products such as beef meatballs, fish balls, pork meatballs, and chicken meatballs.

About Foodline Equipment

- Professional R&D team

- Extensive export experience

- One-stop service

- Strict quality control

In addition to meatball production lines, we also have meat patty forming machines with different output capacities. Please contact us for more details and a quote! WhatsApp/Phone: +86 13838385752.