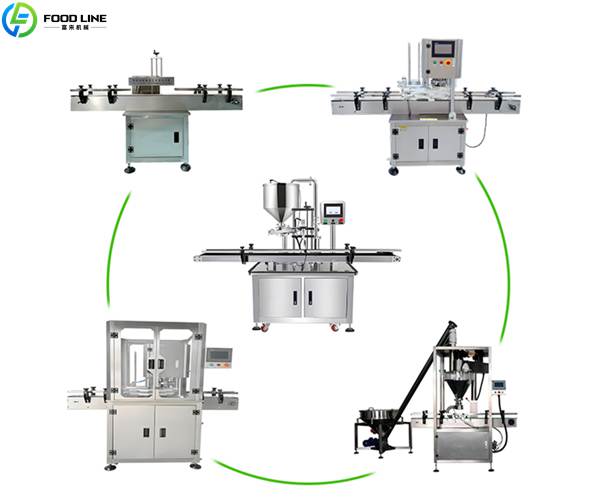

The automatic bottle filling and capping machine is a fully automated filling and capping machine that integrates filling, conveying, and capping. Compared to traditional manual or semi-automatic filling systems, this machine automates the entire process, from raw material intake to finished product packaging, significantly improving production capacity and quality.

Filling and sealing efficiency directly impacts production speed and product qualification rate. For companies seeking to balance production capacity and quality, selecting an automatic filling machine with stable performance, strong adaptability, and ease of operation is undoubtedly the best choice for reducing costs and enhancing efficiency. Now is the best time to upgrade your production line! Contact Us. WhatsApp/Phone: +86 13838385752.

Specifications of Fully Automatic Filling Machine

| Specification | Details |

|---|---|

| Filling range | 100–10000ML (customized according to customer requirements) |

| Filling speed | About 1–50 (Bottle/min) |

| Working pressure | 0.6–0.8MPA |

| Bin volume | About 65L |

| Machine size | About 180*810*1530mm |

| Machine weight | About 200KG |

| Measurement accuracy | ≤5g (Take 20 pumps as an example) |

| Power/voltage | 2.5KW/220V |

Applicable Product Range: Multiple Industries and Multiple Types of Support

This automatic bottle filling and capping machine is widely suitable for the following industries:

- Food Industry: Chili sauce, sesame paste, jam (with fruit pieces), honey, condensed milk, etc.

- Daily Chemical Industry: Toothpaste, scrub, facial cleansing gel, shampoo, etc.

- Industrial Industry: High-viscosity liquid products such as resin colloids, sealants, and asphalt coatings.

This fully automatic filling machine offers high compatibility and efficiency. It is the preferred filling solution for a variety of high-viscosity or particulate-containing products.

Automatic Filling Machines Features

- Smart touchscreen for transparent and controllable operation: Equipped with a highly sensitive industrial-grade touchscreen, the interface integrates parameter settings, filling speed control, and fault notifications. Every setting provides real-time data feedback, ensuring production flexibility and reliability.

- A feeding system designed specifically for high-viscosity and particulate materials: The hopper interior is polished and treated to prevent buildup. It features a large-diameter valve and a pressure-resistant feed mechanism, effectively preventing particle blockage and paste retention, ensuring smooth material feeding.

- Stable and Vibration-Resistant Conveyor System: The conveyor belt features a low-noise, high-strength structure, ensuring stable operation for hours without deflection. Equipped with an anti-shake device and bottle-gripping positioning mechanism, the machine maintains upright and precise alignment, even at high speeds.

- High-Efficiency Automatic Capping System: The capping system utilizes an intelligent torque control system, adjusting torque for different cap materials and specifications. This effectively prevents cap cracking due to overtightening or leaks due to over-loosening.

Advantages of Automatic Bottle Filling and Capping Machine

- Adaptable to both viscous and particulate materials, breaking through traditional methods: Conventional filling equipment often faces problems such as poor discharge and uneven filling when handling highly viscous or particulate-laden fluids. This equipment, with its precisely designed internal piping structure and buffering and flow-guiding system, can easily fill complex materials such as chili sauce, sesame paste, and resin products, truly achieving “one machine, multiple materials.”

- Long maintenance cycle, safer operation: The equipment uses industrial-grade components, resulting in a durable overall structure and a high degree of component compatibility. This allows for long maintenance intervals and minimal daily upkeep, significantly reducing operational pressure.

- More optimized cost control: Compared to manual or semi-automatic filling methods, this equipment doubles production capacity while significantly reducing labor, time, and material waste costs. It’s particularly suitable for medium-sized and larger enterprises planning expansions, adding new lines, and other upgrades.

FAQ

Yes, the device is equipped with an automatic capping system with a torque adjustment function to ensure that the cap is tightened tightly without slipping or leaking.

No, the filling head adopts an anti-drip design and is equipped with a back-suction system to ensure a clean and tidy outlet.

Why Choose Foodline Machinery?

- Focused on the food machinery industry: We have many years of experience in the food machinery industry and have a deep understanding of the processes used for hot sauce, colloids, and industrial coatings. We have also developed a series of auxiliary function modules that more precisely match process characteristics than traditional equipment.

- Flexible customization to support customer needs: The equipment structure and control system can be flexibly adjusted to suit the customer’s bottle shape, cap type, and filling fluid characteristics. Our experienced team of engineers can quickly respond and complete non-standard custom development.

- Stable Equipment: Our equipment undergoes multiple rounds of simulation testing before shipment, ensuring long-term, trouble-free operation. Its stability surpasses comparable equipment in the industry and is suitable for high-volume production environments.

- Global Service System, Guaranteed After-Sales Service: We have a sales and service network in Europe, America, Southeast Asia, and South America, offering a variety of services, including remote guidance and spare parts support, to ensure worry-free equipment operation 24/7.

In addition, we also sell packaging machines and labeling machines. If you are interested in these products, please get in touch with us! WhatsApp/Phone: +86 13838385752.