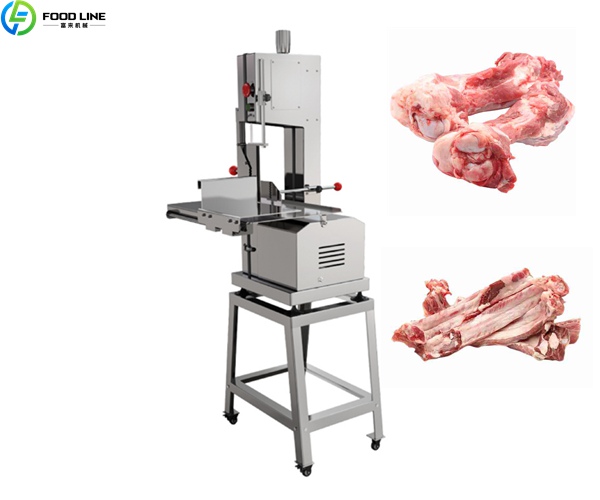

The 400 vertical bone saw meat cutting machine boasts a scientific and stable structure. It can easily handle both hard bones, such as pork and beef, as well as large cuts of meat. This equipment is not only an efficient production helper for meat processing plants and central kitchens, but also an indispensable equipment in the cutting process. If you are interested in this product, please feel free to consult! WhatsApp/Phone: +86 13838385752.

Bone Saw Machine Parameters

| Model | 400 Carbon Steel Bone Saw |

|---|---|

| Motor Power | 2200W (Pure Copper) |

| Rated Voltage | 220V (Customizable) |

| Cutting Speed | 300m/min |

| Saw Blade Model | 2390mm |

| Cutting Height | 0~400mm |

| Cutting Width | 5~250mm |

| Net Weight | 94kg |

| Platform Size | 725×565mm |

| Machine Dimensions | 740×650×1700mm |

Features of Bone Saw Meat Cutting Machine

- Cutting Performance: The 400mm cutting height and 250mm cutting width combination allows for processing large whole bones and large pieces of frozen meat in one go, eliminating the need for repeated cutting. Whether it’s segmenting a whole beef bone or slicing a large piece of frozen meat, it can be efficiently completed, meeting the cutting needs of large-scale production operations and helping to improve production line efficiency.

- Protection Design: The bone saw is equipped with an emergency stop/switch, which instantly shuts down the machine in the event of an emergency, reducing the risk of accidents. The double-push plate structure ensures stable feeding of food and isolates hands from the saw blade, preventing injuries from cutting. The stainless steel workbench is easy to clean and corrosion-resistant, meeting food processing hygiene standards, reducing bacterial growth and ensuring food safety.

- Details: The saw blade ensures stable blade transmission, preventing stuttering or deviation during cutting. The blade adjustment knob precisely adjusts the blade tension based on the food, adapting to different cutting needs. An adjustable pad on the bottom of the machine adjusts to varying floor flatness, ensuring smooth operation and reducing vibration and noise.

Advantages of Bone Saw Machine

- Efficiency: Compared to traditional manual bone saws or smaller equipment, the 400 bone saw boasts faster cutting speeds and larger single-process volumes. This reduces labor input and labor costs.

- Quality: Stable cutting performance ensures smooth, precise cuts, minimizing food waste. For example, when processing marinated meats, uniform cut sizes ensure consistent flavor. When producing pre-prepared meals, standardized bone and meat specifications enhance the appearance and consistency of finished products, helping companies create high-quality products.

- Costs: The machine body is constructed of durable materials, and key components (such as the saw blade pulley and push plate) are designed with performance and longevity in mind. Daily maintenance requires only cleaning the workbench and regularly inspecting the saw blade. These simple steps ensure long-term stable operation, minimizing downtime and component replacement costs.

Customer Success Stories

Case 1: A Mexican factory specializes in beef processing. Its original equipment had insufficient cutting height, requiring repeated splitting to process whole bones. This resulted in low efficiency and uneven bone sizes. The introduction of a 400-model bone saw, with a 400mm cutting height, allowed for direct cutting of whole bones, significantly increasing production capacity. This standardized cutting method resulted in uniform bone segment size, consistent product quality, and increased customer repurchase, becoming a key driver of the company’s expansion.

Case 2: A central kitchen in the United States needed to standardize food cutting standards. The precision of the 400-type bone saw ensures consistent pork and beef bone sizes across all stores, consistently improving the taste of dishes. Furthermore, the equipment’s easy cleaning and maintenance meet the strict hygiene and maintenance requirements of central kitchens. Over a year of operation, the equipment has experienced no downtime, ensuring continuous production line operation.

Why Choose Foodline Machinery?

- Professional R&D and Production Capabilities: We have been deeply engaged in the machinery and equipment industry for 20 years and have an independent R&D team and production base. Our equipment undergoes hundreds of tests and optimizations from design to production, and our core components are independently developed and manufactured. This ensures stable performance and reliable quality, adapting to the complex demands of the meat processing industry.

- Comprehensive After-Sales Service: We provide installation guidance and operational training, teaching employees proper use and routine maintenance. We also conduct regular customer visits to proactively identify equipment hazards and safeguard production.

- Customized Services: Our equipment supports customized services. We can select the right equipment based on your company’s specific processing needs, precisely matching it to your production line and solving your problems at a lower cost.

The 400 vertical bone saw meat cutting machine, with its efficient, safe, and stable performance, has become the choice of many meat processing companies. If you’re struggling with low meat-cutting efficiency and inconsistent quality, try the 400 vertical bone saw and experience a new level of efficiency! Welcome to contact us! WhatsApp/Phone: +86 13838385752.

In addition to the 400 model, we also have 210, 250, and 280 models of bone sawing machines.