If you’re looking to increase production and reduce costs, investing in a brine injection machine is a wise choice. Our equipment is more than just a tool. It’s a solution that boosts your efficiency. Our goal is to increase your profitability while ensuring excellent results with every batch. If you are interested in this product, please contact us! WhatsApp/Phone: +86 13838385752.

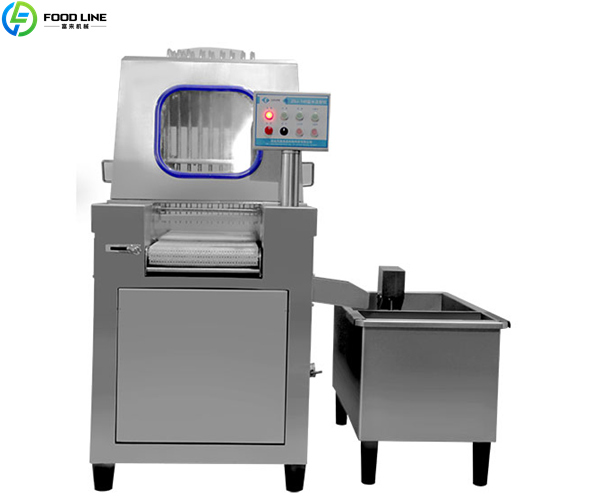

Brine Injector Equipment Overview

The brine injection machine is designed to inject brine solution and marinade into meat. This shortens marinating time, tenderizes meat, and increases product yield. Ultimately, this results in a more flavorful product and higher batch yields. Made of stainless steel and meeting food hygiene standards, this equipment is a reliable and safe choice for professional processors.

Specifications of Brine Injector Machine

| Model | FL-120 |

|---|---|

| Injection Needles | 120 pcs |

| Production Capacity | 500-1500 kg/h |

| Motor Power | 1.5 kW (Variable Frequency) |

| Water Pump Power | 3 kW |

| Water Pump Pressure | 2 — 6.3 kg (adjustable) |

| Tank Width | 420 mm |

| Needle Vertical Stroke | 170 mm |

| Injection Speed | Variable Frequency Control |

| Chain Step Distance | 120 mm |

| Optional Needle Spec. | Ø304 mm |

| Host Machine Dimensions | 1350*1250*1720 mm |

| Feeder Cart Dimensions | 860*460*650 mm |

| Weight | 550kg |

Features of Meat Injector Machine

Stainless Steel Construction

The side panels, frame, water tank, and needle assembly are all made of SUS304 stainless steel, ensuring hygiene, corrosion resistance, and a long service life.

Needle Protection

The injection needle automatically lifts upon encountering bone, preventing damage and supporting bone-in meat processing.

Water Distribution Tank Design

Prevents needle clogging and ensures smooth injection.

Filtration System

A top-mounted filter removes fine meat particles, keeping the brine clean and preventing clogging.

Pressure Control

The system’s built-in accumulator maintains stable pressure for even brine distribution.

Injection Capacity

Equipped with 120 stainless steel needles, it can process 500-1500 kg of meat per hour, with adjustable pump pressure between 2 and 6.3 bar.

Clean and Maintain

The removable chain plate design allows for easy cleaning and ensures the highest hygiene standards.

Insulated Design

The storage tank can be insulated for injecting marinades containing oil or fat, maintaining consistent injection quality.

Free Quote! WhatsApp/Tel: +86 13838385752.

Advantages of Saline Injector Machine

Efficiency

Marination time is significantly reduced, increasing yields.

Flavor

Seasoning is evenly distributed, ensuring excellent taste and uniform texture.

Yield

Optimized moisture retention and marinade absorption allow processors to produce more product with the same ingredients.

Labor

Automation reduces manual operations, lowers labor costs, and minimizes errors.

Versatility

Suitable for a variety of meats, including ham, bacon, poultry, and seafood.

Performance

Utilizes high-strength bearings, a pure copper motor, a stainless steel pump, and electrical components that meet national standards to ensure long-term stability.

Working Principle of Brine Injector

The operating principle of this brine injection machine is simple yet efficient. Meat is fed into the machine via a conveyor system, where a series of injection needles evenly inject brine into the muscle fibers. The machine’s water circulation and filtration systems ensure continuous particle removal, preventing clogging of the pump or needles.

An automatic needle protection system ensures the needle automatically lifts if it encounters bone or hard objects, preventing damage. An integrated pressure stabilizer ensures consistent injection. The operator can adjust the step speed, pressure, and injection volume.

For meats marinated in oil or sauce, the machine can be equipped with an insulated reservoir to maintain a consistent temperature and ensure uniform injection.

Applicable Products

This brine injection machine is suitable for a variety of meat processing needs and is suitable for pork, beef, lamb, fish, chicken, and other meat products. It is also ideal for manufacturers of ham, kebabs, grilled meats, and similar foods. Its robust design, simple operation, and convenient cleaning system ensure consistent, high-quality results for a wide range of meat processing applications.

FAQ

Equipped with 120 needles, this machine can process 500-1500 kg of meat per hour, making it ideal for medium- to large-scale production.

Yes. The insulated storage tank is suitable for injecting oil-based marinades or sauces.

Yes. Thanks to its automatic lifting needle design, the machine can process both boneless and bone-in meat without damaging the needles.

Foodline Machinery – Your Trust Partner

When searching for a brine injection machine, choosing the right supplier is just as important as choosing the right machine itself. We stand out with the following advantages:

- Industry Experience: Years of expertise specializing in food machinery and equipment.

- Customization Options: Customize machines to meet your specific production needs.

- High-Quality Components: Stainless steel construction, copper-core motors, and rugged pumps ensure reliability.

- After-Sales Support: From installation to training and maintenance, our services ensure long-term performance.

If you’re looking for a solution to upgrade your meat processing line, our brine injection machine is the ideal choice. Whether you process ham, bacon, poultry, or seafood, this commercial brine injection machine can help you meet your needs. Contact us today to learn more about our saline injection machines! WhatsApp/Phone: +86 13838385752.

Besides this, we also sell bone sawing machines.