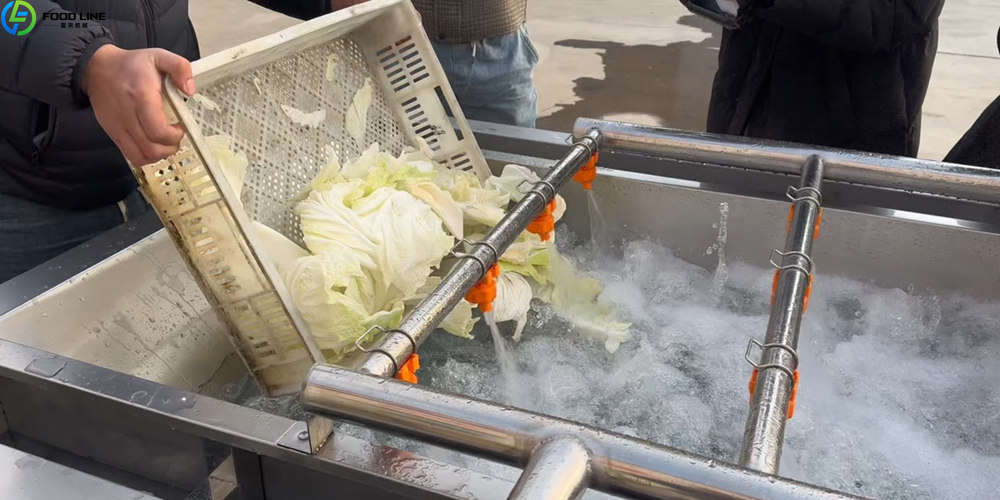

The Bubble Washing machine is a medium-to-large-scale cleaning machine designed for agricultural products such as vegetables and fruits. Based on traditional bubble washing, it incorporates a high-pressure spray system and a lifting and conveying structure. This achieves multi-stage cleaning and continuous discharge, improving cleaning depth and production continuity.

The bubbling cleaning machine can also be added to the production line to form a production line with the blanching machine, elevator, etc. If you are interested in this device, please feel free to contact us! WhatsApp/Phone:+86 13838385752.

Specifications of Vegetable Bubble Washer

| Model | FL-400A |

|---|---|

| Size | 4000 × 1650 × 1800 mm |

| Voltage | 380 V |

| Power | 4.45 KW |

| Total Output | 800-1000 kg/h |

Features of Fruit Bubble Washing Machine

High-Pressure Spray and Bubble Cleaning Dual System

The top of the machine is equipped with a circulating water high-pressure spray device. While bubbles are tumbling and cleaning, spraying is applied downward from above. This achieves three-dimensional cleaning, enhancing cleaning effectiveness for complex vegetables.

Elevating Discharge and Anti-Recontamination Design

The discharge section features a clean water spray to prevent re-contamination of the material during discharge. The lifting mesh belt utilizes food-grade plastic chain plates to reduce friction damage to the material surface. This is particularly suitable for delicate products such as strawberries, cherry tomatoes, and tender leafy vegetables.

Conveyor System

A dedicated scraper is installed on the inside of the conveyor belt. It helps push the material out thoroughly and also stabilizes it during low-water cleaning. This prevents it from scattering or accumulating due to water turbulence, ensuring uniform cleaning.

Circulating Water Tank

A separate small water tank is located on the side of the machine, enabling efficient water circulation and filtration. This improves water resource utilization, reduces freshwater consumption, and reduces wastewater discharge.

Customizable

The lifting structure can be customized according to customer needs, and features such as UV sterilization and ozone sterilization can be added.

Free Quote! WhatsApp/Tel: +86 13838385752.

Advantages of Bubble Washing Machine Vegetable and Fruit

Thorough Cleaning

The dual air bubble and spray cleaning mechanism effectively removes sand and impurities trapped in crevices and on surfaces.

Low Material Damage

The plastic chain elevator and water flow design effectively ensure material integrity.

Production Line Compatibility

Adjustable discharge height and speed make it suitable for subsequent processes such as blanching, slitting, and packaging.

Water Saving

The circulating water system effectively reduces production costs and meets environmental requirements.

Customization Support

A variety of customization options are available to meet the specific needs of different product categories and production lines.

Applicable Products

- Leafy vegetables: spinach, lettuce, etc.

- Fruits: tomatoes, peppers, etc.

- Flowers: cauliflower, strawberries, etc.

- Mushrooms: enoki mushrooms, shiitake mushrooms, etc.

Custom Success Stories

Case 1: Production line at a US fruit processing company

The company’s original cleaning process was inefficient and resulted in high material loss. After introducing a bubble washer, it integrated with the existing blanching and drying machines, reducing cleaning loss and achieving a stable processing capacity of 900 kg per hour, improving overall production efficiency.

Case 2: Large-Scale Vegetable Distribution Center

A French company previously used a traditional rinsing method, which consumed a lot of water and resulted in uneven cleaning results. After switching to this equipment, the circulating water system and high-pressure spray function improved vegetable cleanliness, resulting in a significant increase in customer satisfaction.

Case 3: A German Frozen Vegetable Exporter

This company primarily exports its products, placing high demands on cleanliness and microbial control. Adding ozone sterilization to their equipment not only achieved the desired cleaning results but also reduced the total bacterial count, earning them multiple international food safety certifications.

About Foodline Equipment

- Professional Manufacturing Experience: We have a dedicated R&D team, and all products undergo rigorous testing before export.

- Customization: We can customize solutions based on your production volume and process requirements.

- One-Stop Service: We provide comprehensive support, from equipment selection and production line design to installation and commissioning guidance.

- Export Experience: Our equipment has been exported to numerous regions and countries, including North America, South America, and Europe.

Whether it is a new production line or an upgrade of existing equipment, this equipment can be used. If you have any related needs, please contact us for a quote and information. We also offer other models of bubble washers. WhatsApp/Phone: +86 13838385752.