This commercial garlic peeling machine uses an air compressor as its primary power source. Through integrated electrical control, it automatically guides, peels, and discharges garlic. Compared to traditional manual peeling, this machine can process large quantities of garlic in a shorter time, with a single machine output of up to 70 kg, meeting the needs of small and medium-sized businesses as well as large production lines.

The machine is equipped with a peeling drum and incorporates multi-point jet vortex pressurization technology to ensure uniform pressure during the peeling process. This design allows for efficient peeling while maintaining the integrity of the garlic cloves. A garlic peeler can be used standalone or integrated into a garlic production line. If you’re interested in this machine, please contact us! WhatsApp/Phone: +86 13838385752.

Parameters of Commercial Garlic Peeling Machines

| Model | FL-TP300 |

|---|---|

| Voltage | 220V |

| Power | 2.2kw |

| Weight | 100kg |

| Output | 70kg |

| Dimensions | 600*600*1280mm |

Features of Garlic Peeling Machines

Degree of Automation

The machine is controlled by both electricity and pneumatics. The entire garlic feeding, peeling, and discharging process requires no manual intervention, improving production efficiency.

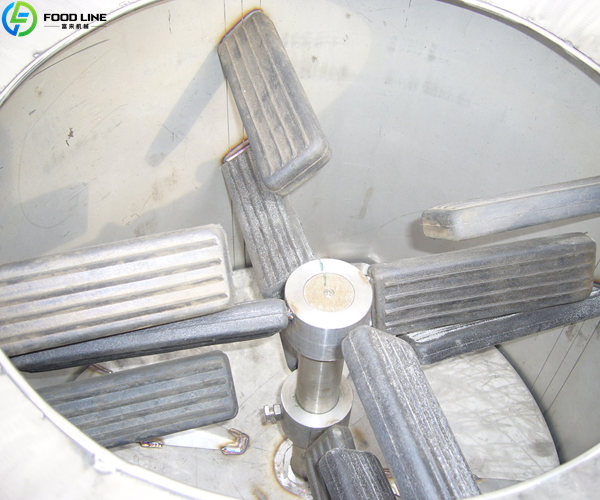

Multi-point Jet Vortex Pressurization Technology

This design ensures uniform and thorough peeling, effectively reducing damage to the garlic cloves and maintaining a smooth and clean surface.

Built-in Peeling Bucket

During operation, the peeling bucket synchronizes with other processes. This design shortens operation time and improves overall efficiency.

Application Scenarios

It is suitable for vegetable processing plants, condiment processing plants, instant noodle factories, and individual businesses in large wholesale markets.

Production Capacity

With a single machine output of 70kg, it can meet the daily needs of small and medium-sized enterprises while also providing stable operation on production lines.

Free Quote! WhatsApp/Tel: +86 13838385752.

Advantages of Garlic Peeler

Save Labor Costs

Traditional manual garlic peeling is not only time-consuming and labor-intensive, but also highly labor-intensive. This commercial garlic peeler replaces multiple manual operations, significantly reducing labor costs.

Quality

The peeling machine utilizes advanced vortex pressure technology to ensure that the garlic is not damaged during the peeling process. This leaves the garlic cloves intact and their appearance ideal for further processing or direct sales.

Operation and Maintenance

The machine features a compact structure, a small footprint, and a user-friendly interface. Even first-time users can quickly master the process. Daily cleaning and maintenance are also very convenient.

Versatile

Whether used as a stand-alone unit or integrated into a garlic production line, this machine integrates with existing processes without requiring major modifications.

Stable and Durable

The use of high-quality materials and advanced manufacturing processes ensures long-term stability and longevity.

Working Principle of Garlic Peeling Machine

The peeling machine operates as follows:

- Material Guidance: The equipment automatically conveys the garlic into the peeling drum via an electrical control system.

- Peeling: An air compressor generates high-pressure airflow, and a multi-point spray device creates a vortex-like pressure increase within the peeling drum, separating the garlic skin from the cloves.

- Synchronized Processing: The built-in peeling drum and spray device operate synchronously to ensure uniform pressure distribution on the garlic.

- Discharging: After peeling, the garlic is automatically discharged, and the peeled skin is discharged through a dedicated channel, maintaining a clean working environment.

Why Choose Foodline Equipment

Professional Manufacturing Experience

We have many years of R&D and manufacturing experience in the food machinery field. We are able to deeply understand customer needs and provide practical and efficient equipment solutions.

Quality Assurance

Our equipment is CE-certified. Every commercial garlic peeling machine undergoes rigorous testing before shipment to ensure stability and durability.

After-Sales Service

From equipment selection and installation and commissioning to operator training and long-term maintenance, we provide comprehensive support to ensure customers can use their equipment smoothly.

Customizable Solutions

In addition to providing standard equipment, we can also provide customized designs based on your production scale and process flow.

Export Experience

Our equipment has been exported to numerous countries and regions and has received high praise from our customers.

Our commercial garlic peeling machine not only saves labor costs but also ensures garlic quality. It’s a valuable tool for processing vegetables, condiments, instant noodles, and even wholesale markets. See how our Russian customers use the garlic peeling machine. If you’re looking for a reliable machine, please contact us! WhatsApp/Phone: +86 13838385752.