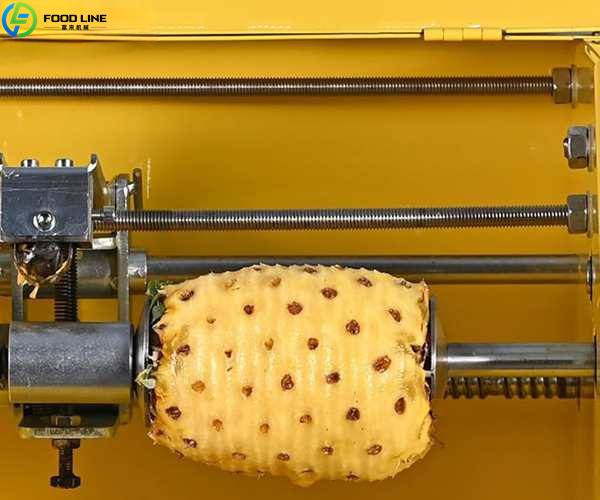

Commercial pineapple peeler is a highly efficient automated equipment designed for restaurant chains, food processing plants, and canned food production lines. It uses a 304 food-grade stainless steel body and an adaptive knife system. The equipment can automatically complete the entire process of peeling, cutting, core removal, and slicing the pineapple. If you want to know more about this product, please get in touch with us! WhatsApp/Phone: +86 13838385752

Pineapple Peeling Machine Parameter

| Type | Pineapple Peeling Machine |

|---|---|

| Capacity | 500 pcs/hour |

| Peeling Thickness | Adjustable 1.5–15mm |

| Fruit Height Range | 80–400mm |

| Fruit Diameter Range | 80–220mm |

| Coring Diameter | Customizable 16–30mm |

| Power | 1.5kW (220V, 50Hz) |

| Weight | 400kg |

| Dimensions (L×W×H) | 2450×900×1700mm |

Advantages of Commercial Pineapple Peeler

- Efficiency: Our automatic pineapple peeling machine is very efficient. It can process 500-1000 pineapples per hour, which is equivalent to the workload of several skilled workers. Based on 8 hours of operation per day, it can replace about 1920 man-hours per month, greatly reducing operating costs.

- Pulp utilization: Equipped with self-adaptive blade technology, the machine can automatically sense the surface shape of the pineapple and intelligently adjust the peeling path. Compared with manual peeling, it effectively reduces pulp waste. It can produce more pulp and further increase the output value.

- Operational safety: The closed operation cabin is equipped with an automatic discharging system to prevent skin discomfort caused by bromelain splashing. It also avoids itching, stinging, and other problems caused by manual contact. The equipment complies with CE safety certification and ISO9001 quality management system standards to ensure safety and standardization during use.

Peeling Machine Features

- 304 stainless steel: The whole machine adopts a food-grade 304 stainless steel one-piece design. The equipment has strong corrosion resistance and rust resistance. The smooth, seamless structure has no dead corners, making cleaning more convenient and greatly improving the efficiency of hygiene management. It has passed the food machinery industry hygiene and safety certification to ensure that every process meets food safety standards.

- AI visual recognition + adaptive control system: The equipment has a built-in AI visual recognition system and adaptive control algorithm, equipped with a high-definition touch screen operation interface and a powerful fruit shape database, which can accurately identify parameters such as the height and diameter of the pineapple. The system intelligently adjusts the blade trajectory according to the different shapes of each fruit. It greatly improves the peeling consistency and product qualification rate, and significantly reduces manual intervention.

- Modular multi-purpose knife set: The knife head is designed to be quickly disassembled, and can be replaced with a slicing knife, core knife, or skinning knife within 5 minutes to meet different processing needs such as fruit cones, fruit segments, and fruit slices.

- IoT Remote Management: It supports production statistics, fault warning, and consumable life monitoring, and can receive order parameter instructions online to achieve production scheduling.

FAQ

The commercial pineapple peeler is equipped with a laser scanning system and a pneumatic fruit holding device, which can detect the fruit size in real time and automatically adjust the chuck position and the movement trajectory of the cutter head. Whether it is a mini pineapple or a giant pineapple, it can achieve a high coverage rate of peeling to ensure complete peeling.

Yes, all models are CE certified and ISO9001 quality management system certified. English operating manuals, mechanical test reports and export-grade wooden packaging that meets international transportation requirements can be provided with the equipment to meet the import standards of countries and regions such as Europe, America, and Southeast Asia.

The equipment is made of stainless steel, which is easy to clean and maintain. After stopping, rinse the knife holder and the slag tank with clean water. The maintenance process does not require professional operation, which effectively reduces labor costs and downtime.

Why Choose Foodline Machinery?

We are committed to providing smarter, safer, and more efficient solutions. Our pineapple peeling equipment is made of 304 food-grade stainless steel and advanced technology to comprehensively improve peeling accuracy, pulp utilization, and operational safety. Not only that, but we also provide a complete after-sales service system. It includes remote technical support, operation training, and regular maintenance guidance. We ensure customers have no worries during use. You may be a factory, a fruit and vegetable processing company, or an export trading company. We can create a cost-effective solution for you.

In addition to peeling machines, we also have washing machines for processing fruits and vegetables. If you have any needs, don’t hesitate to get in touch with us. WhatsApp/Phone: +86 13838385752