Liquid filling machines are automated equipment designed to streamline the packaging process for liquid materials. They are specifically designed to handle materials of varying viscosities and eliminate issues such as dripping and air bubbles. Unlike general-purpose filling machines designed for low-viscosity liquids, these machines are uniquely optimized to effectively address issues such as adherence to surfaces, uneven flow, and air entrapment that can occur during the filling process.

Whether it is filling daily chemicals or industrial barrel materials, the machine can maintain accuracy and efficiency. Welcome to contact us. WhatsApp/Phone: +86 13838385752.

Specifications of Filling Machine

| Parameter | Specification |

|---|---|

| Filling Range | 50–5000ML (customized according to customer requirements) |

| Filling Speed | 10–20 Bottles/min (Take 500ml as an example) |

| Working Pressure | 0.6–0.8MPA |

| Machine Size | About 12007501200 mm (length * width * height) |

| Machine Weight | About 150KG |

| Measurement Accuracy | ±1% (Depending on the specific material) |

| Power/Voltage | 1.0KW / 220V |

Features of Liquid Filling Machine

- Adaptive Viscosity Handling: This liquid filling machine is equipped with an adjustable pumping system and variable speed controller to accommodate liquid materials of varying viscosities. For example, by adjusting pressure and flow, it can smoothly handle low-viscosity liquids like alcoholic beverages, as well as high-viscosity materials like essential oils. This ensures uniform filling, preventing blockages and uneven distribution.

- Anti-Drip and Anti-Splash Design: Liquid materials can easily drip or adhere to nozzles, potentially contaminating packaging or causing material waste. This machine’s design effectively prevents residual liquid from dripping onto containers or conveyors.

- High-Precision Filling Control: Equipped with a servo-driven pump and digital sensors, the machine achieves filling accuracy within ±1%, even for thick liquids.

- Flexible container compatibility: It supports a wide range of container types, including tubes, bottles, cans, and drums made of materials such as plastic, glass, and metal. The device easily adapts to different container sizes and shapes.

Advantages of Filling Equipment

- Reduced Material Waste: The anti-drip design and precise volume control minimize liquid waste, which is especially important for high-cost products such as cosmetic serums or ointments. This prevents residual liquid from clinging to the nozzle or spilling. Compared to manual filling or conventional filling machines, businesses can reduce material loss.

- Improved Product Quality: Eliminating bubbles and ensuring uniform filling enhances a product’s visual appeal and stability. For example, bubble-free essences maintain a smooth texture, while precisely filled alcohol meets dosage requirements, reducing the risk of non-compliance in the pharmaceutical industry.

- Improved Production Efficiency: Automated filling processes reduce reliance on manual labor. Production time is significantly reduced compared to manual methods.

- Cross-Industry Versatility: This machine can handle a wide range of viscosities and container types, making it suitable for various industries, including food and chemicals. This versatility eliminates the need for separate equipment for different products, reducing overall investment costs for companies with diverse product lines.

Suitable Products

This liquid filling machine is suitable for liquid materials of various viscosities and is an indispensable tool in three key industries:

- Food Industry: Suitable for beverages, sauces, and more. Its anti-drip feature ensures clean cans, while its defoaming technology maintains a smooth mouthfeel for these liquid edibles.

- Cosmetics Industry: Suitable for filling lotions, serums, makeup removers, and toners. Precise filling ensures consistent product volume in tubes or cans, while its anti-drip nozzle ensures hygienic skincare products.

- Pharmaceutical Industry: Suitable for filling essential oils, test reagents, and eye drops. The equipment meets strict hygiene standards and provides precise dosing, making it suitable for regulated medical products.

Customer Success Stories

Case 1: Mr. García owns an olive oil production company in Spain. With the growing demand for olive oil, his traditional manual bottling process could no longer keep up with the increasing orders. Mr. García invested in our fully automatic liquid filling and sealing machine. Its precise volumetric filling and hygienic stainless steel contact parts ensure zero product waste and consistently high quality.

Customer feedback: “This liquid filling machine has transformed our production. The transition was smooth, training was easy, and we are now ready for further expansion.”

Case 2: A mid-sized skincare brand in Kuala Lumpur was about to launch a new moisturizing lotion. They needed an efficient, gentle, and precise filling system to handle their delicate, low-viscosity formula and prevent contamination. They chose our filler. Its adjustable filling range and user-friendly controls perfectly matched their small-batch, high-mix production needs.

Customer feedback: “Our team loves this filler. It saves time, reduces waste, and maintains high quality.”

Foodline Machinery-Your Trust Partner

Choosing the right liquid filling machine requires a partner who understands the mechanical world. Our company stands out thanks to three key advantages:

- 20 Years of Equipment Experience: We are a major food machinery company with 20 years of experience. We also have a dedicated R&D team and dedicated after-sales service.

- Rigorous Quality Testing: Each liquid filling machine undergoes continuous operational testing to verify its durability and accuracy. We use high-quality components to ensure long-term reliability.

- End-to-End Support: We provide more than just equipment: Our team also provides operator training and 24/7 technical support, ensuring your production line runs smoothly even during peak demand.

Liquid filling machines are specialized tools that can transform liquid packaging, eliminating problems like dripping, bubbles, and inefficiencies to meet the needs of diverse industries. Choosing the right manufacturer ensures you get a machine that meets your needs, making it a wise long-term investment. Welcome to consult! WhatsApp/Phone: +86 13838385752.

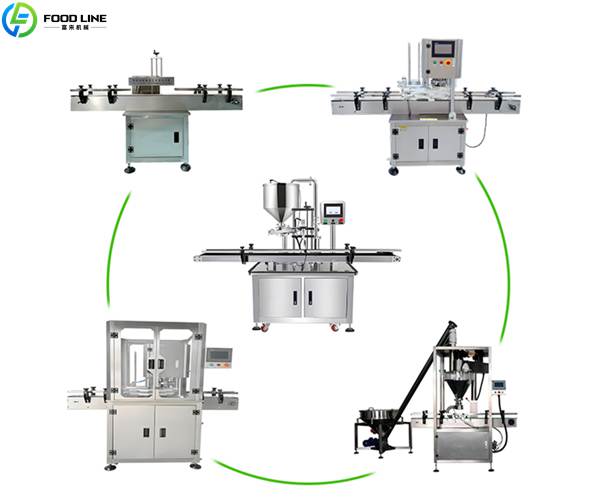

Additionally, our company offers packaging machines and labeling machines for sale.