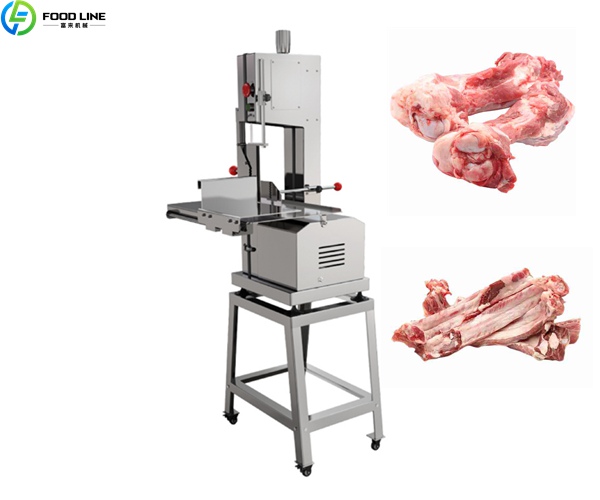

How to quickly, efficiently, and safely cut large bones or whole pieces of frozen meat has always been a critical challenge for meat processing operators. Traditional manual bone sawing is inefficient, unsafe, and produces unsightly finished products. To address this need, the 280 meat and bone saw machine, with its powerful cutting capacity, sophisticated structural design, and safe, user-friendly features, is an ideal choice for medium- to large-scale meat processing facilities.

Welcome to contact us for more information! WhatsApp/Phone: +86 13838385752.

Bone Saw Machine Parameters

| Specification | Details |

|---|---|

| Product Name | FL-B280 |

| Motor Power | 2200W (Pure Copper) |

| Rated Voltage | 220V (Customizable) |

| Cutting Speed | 300m/min |

| Saw Blade Model | 1710mm |

| Cutting Height | 0~280mm |

| Cutting Width | 5~160mm |

| Net Weight | 48kg |

| Platform Size | 570×370mm |

| Body Size | 590×500×910mm |

Features of Meat and Bone Saw Machine

- The 280 Bone Saw is a commercial tabletop bone saw specifically designed for processing large bones and large frozen meats. Its overall structure is constructed of carbon steel and equipped with a food-grade stainless steel worktable, which is rust-resistant, corrosion-resistant, easy to clean, and fully complies with food industry hygiene standards.

- With a cutting height of up to 280mm and a cutting width of 160mm, this machine can handle nearly all the large-sized bone segmentation needs commonly encountered in catering and meat processing plants. The worktable, measuring 570mm long and 370mm wide, provides ample space for placement and operation when processing large bones or whole pieces of frozen meat, enhancing work efficiency.

- The bone saw is equipped with a double push-plate safety mechanism and a red emergency stop button, ensuring immediate interruption in emergencies and protecting the operator. The machine also features a blade tension adjustment knob, allowing users to quickly adjust the blade tension according to the hardness of the material, extending the blade’s life.

- The simple control panel and one-touch on/off switch make operation efficient and intuitive. The layout of the motor’s heat dissipation holes is also reasonable, which helps the machine maintain stable operation under long-term high loads.

Advantages of Bone Saw Machine

Compared to traditional manual bone saws or low-end bone saws, the 280 bone saw offers significant advantages in functionality and performance:

- Large cutting range: Cutting heights up to 280mm and widths up to 160mm allow for portioning whole fish, large bones, and whole frozen meat, reducing pre-processing steps.

- Highly Safe Operation: An emergency stop switch and dual safety push plates prevent hand injuries from misoperation, ensuring personnel safety.

- Easy-to-maintain design: The saw blade is easily disassembled for cleaning, and the motor dissipates heat efficiently, minimizing maintenance.

- Small footprint: The tabletop machine measures only 910mm in height, 590mm in length, and 500mm in width, making it ideal for medium- to large-scale restaurant kitchens or meat processing rooms.

- Powerful power: The efficient motor and high-quality saw blade effortlessly handle cutting high-density and high-hardness aggregates.

Bone Saw Machine Equipment Operating Procedure

To ensure optimal use of your meat and bone saw machine, the following is a recommended standard operating procedure:

- Equipment Inspection: Verify that the saw blade is properly tensioned, the emergency stop switch is engaged, and the power connection is secure.

- Blade Adjustment: Adjust the blade tension using the knob according to the thickness and hardness of the material being cut.

- Material Positioning: Place frozen meat or large bones flat and evenly on the stainless steel workbench, keeping them as close to the edge as possible to ensure stability.

- Machine Start: Press the green start button and observe whether the machine operates smoothly.

- Safe Push: Use the dual push plates to gently push the material toward the saw blade, avoiding direct hand contact.

- When cutting is complete: Turn off the power, remove the saw blade promptly for cleaning, wipe the workbench, and keep the machine dry.

- Regular Maintenance: Regularly check the motor cooling vents for unobstructed space and lubricate transmission components to extend the machine’s service life.

FAQ

During normal operation, the noise level is within a reasonable range, much lower than that of traditional bone sawing methods.

The workbench is made of food-grade stainless steel, which is corrosion-resistant and will not rust easily with proper maintenance.

The saw blade is easy to install and remove, and detailed instructions are included, so even beginners can quickly master it.

Maintenance is simple. Regular cleaning, checking the blade tension, and proper lubrication of the transmission components are all that’s required.

Why Choose Foodline Machinery?

We have extensive industry experience and a mature after-sales system in the R&D, production, and sales of food machinery, providing professional and reliable support to our customers. Choosing us will give you:

- Factory Direct: We operate our own factory, eliminating middlemen and ensuring transparent pricing.

- Professional Manufacturing: We possess years of experience and qualifications in food machinery manufacturing.

- Various Models Available: Choose a model based on your requirements to meet diverse needs.

- After-Sales Service: We offer remote video guidance and repair support.

If you’re looking for a bone sawing machine that efficiently cuts large bones, whole fish, and frozen meat while maintaining safety and hygiene standards, the Model 280 bone saw is definitely worth considering. Contact us now for more product videos and quotes. WhatsApp/Phone: +86 13838385752.

In addition, we also have 210, 250 models of meat and bone saw machines.